2-30 PERIODIC MAINTENANCE

Maintenance Procedure

Drive Train

Drive Chain Lubrication Condition Inspection

•

If a special lubricant is not available, a heavy oil such as

SAE 90 is preferred to a lighter oil because it will stay on

the chain l onger and provide better lubrication.

•

If the chain appears especially dirty, clean it before lubri-

cation.

CAUTION

The O-rings between the side plates seal in the lu-

bricant between the pin and the bushing. To avoid

damaging the O-rings and resultant loss of lubri-

cant, observe the following rules.

Use only kerosene or diesel oil for cleaning of the

O-ring of the drive chain.

Any other cleaning solution such as gasoline

or trichloroethylene will cause deterioration and

swelling of the O-ring.

Immediately blow the chain dry with compressed air

after cleaning.

Complete cleaning and drying the chain within 10

minutes.

•

Apply oil to the sides of the rollers so that oil will penetrate

to the rollers and bushings. Apply the oil to the O-rings so

that the O-rings will be coated with oil.

•

Wipe off any excess oil.

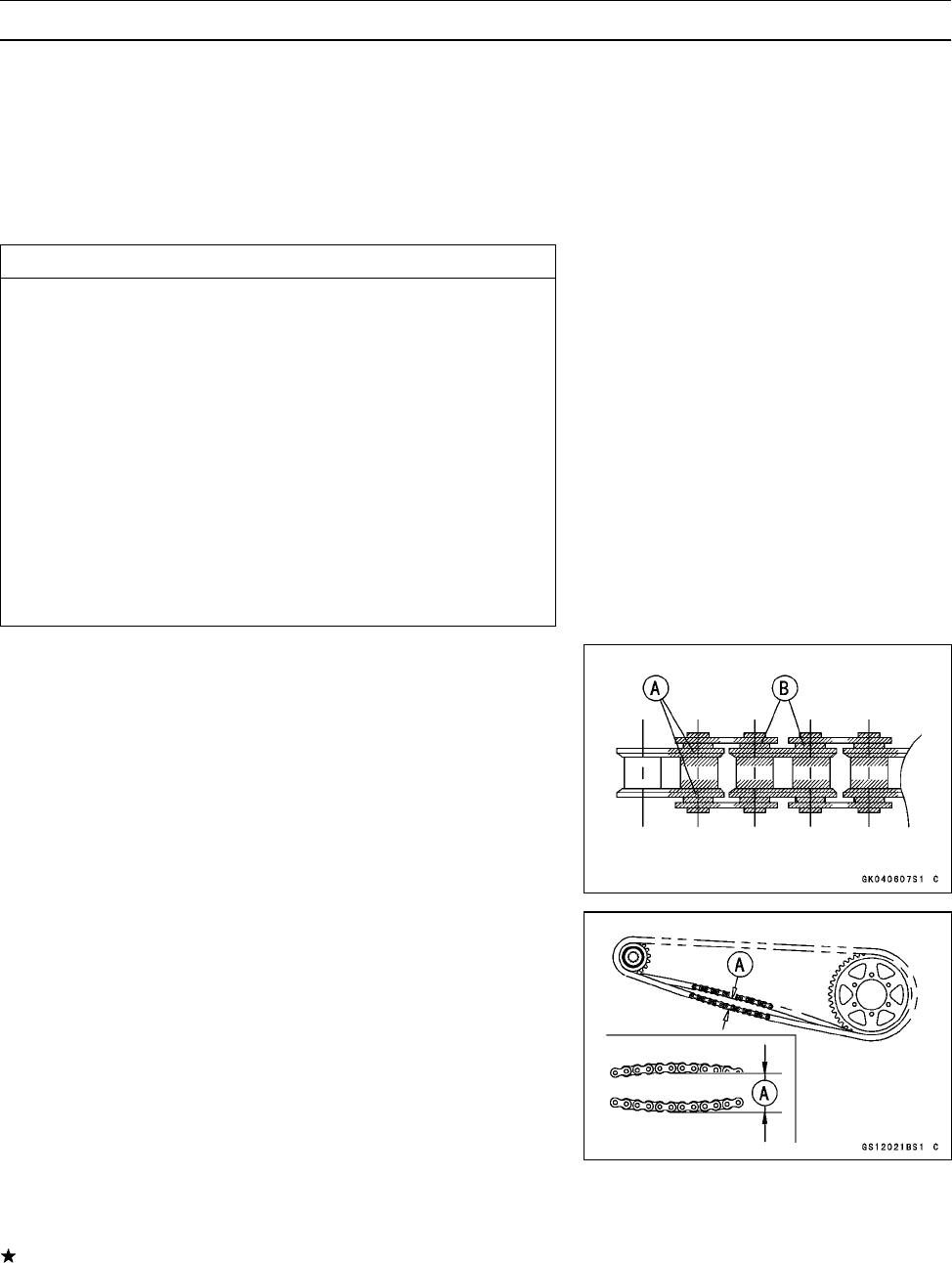

Oil Applied Areas [A]

O-ring [B]

Drive Chain Slack Inspection

NOTE

○

Check the slack with the motorcycle setting on its side

stand.

○

Clean the chain if it is dirty, and lubricate it if it appears

dry.

•

Check the wheel alignment (see W heel Alignment Inspec-

tion).

•

Rotate the rear wheel to find the position where the chain

is tightest.

•

Measure the vertical movement (chain slack) [A] midway

between the sprockets.

If the chain slack exceeds the standard, adjust it.

Chain Slack

Standard: 30 ∼ 35 mm (1.2 ∼ 1.4 in.)

www.zxforums.com

www.zxforums.com

www.zxforums.com

www.zxforums.com

www.zxforums.com

www.zxforums.com

www.zxforums.com