CRANKSHAFT/TRANSMISSION 9-19

Crankshaft and Connecting Rods

•

Install new bolts in reused connecting rods.

•

Dent both bolt head and bolt tip with a punch as shown.

•

Before tightening, use a point micrometer to measure the

length of new connecting rod bolts and record the values

to find the bolt stretch.

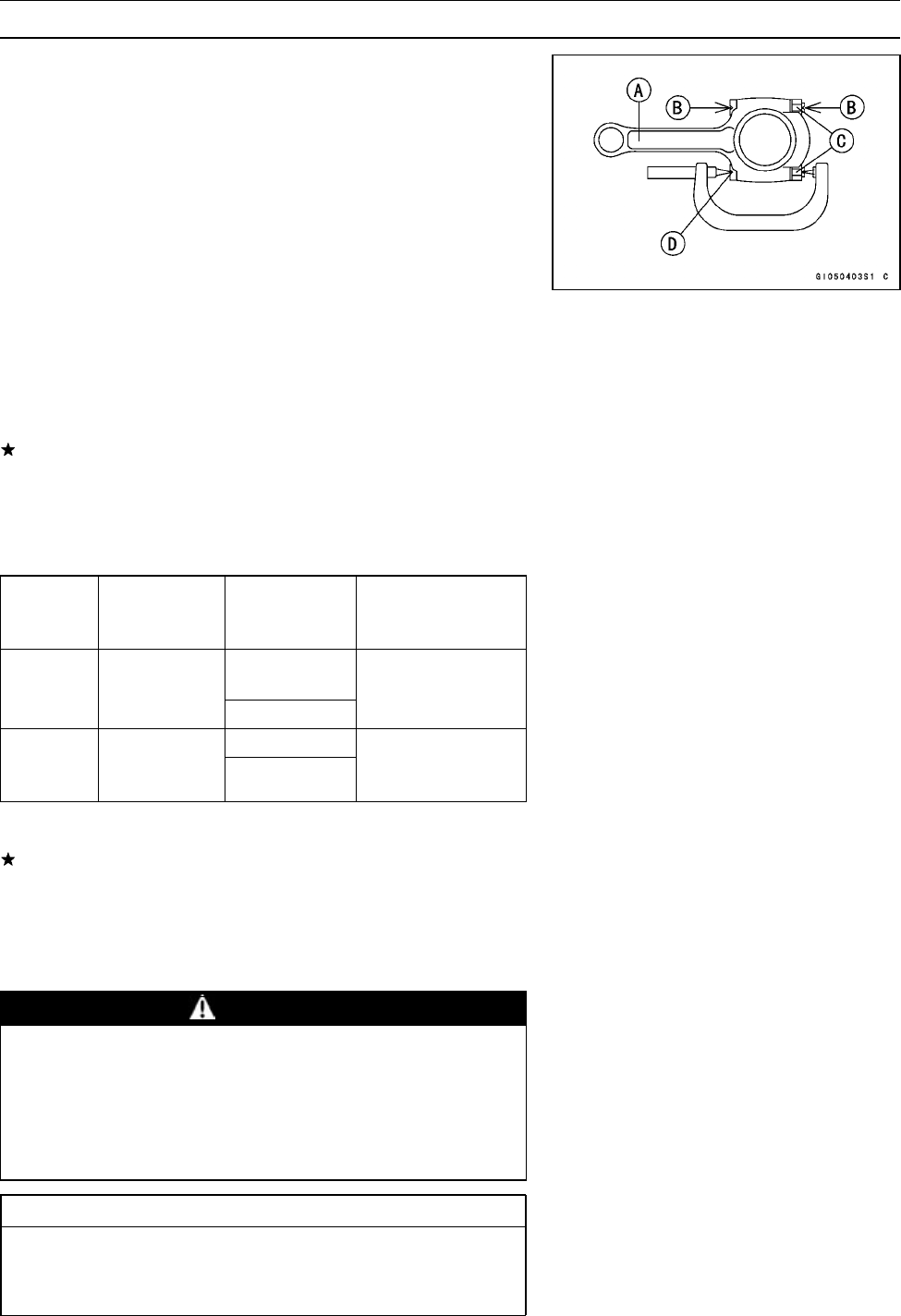

Connecting Rod [A]

Dent here with a punch [B].

Nuts [C]

Fit micrometer pins into dents [D].

•

Apply a small amount of molybdenum disulfide oil solution

to the following.

Threads of Nuts and Bolts

Seating Surfaces of Nuts and Connecting rods

•

Tighten the big end nuts until the bolt elongation reaches

the length specified in the table.

•

Check the length of the connecting rod bolts.

If the stretch is more than the usable range, the bolt has

stretched too m uch. An overelongated bolt may break in

use.

Bolt Length after

tightening

–

Bolt Length before

tightening

=

Bolt Stretch

Connect-

ing Rod

Assy

Bolt Nut

Usable Range of

Connecting Rod

Bolt Stretch

Attached to

new con-rod

New

Use the bolts

attached to

new con-rod.

New

0.24 ∼ 0.34 mm

(0.0094 ∼ 0.0134

in.)

Used

Used

Replace the

bolts with new

ones.

New

0.24 ∼ 0.34 mm

(0.0094 ∼ 0.0134

in.)

(2) Rotation Angle Method

If you don’t have a point micrometer, you may tighten the

nuts using the “Rotation Angle Method”.

•

Be sure to clean the bolts, nuts and connecting rods thor-

oughly with a high-flash point solvent, because the new

connecting rods, bolts and nuts are treated with an anti

-rust solution.

WARNING

Clean the bolts, nuts and connecting rods in a well

-ventilated area, and take care that there is no spark

or flame anywhere near the w orking area. This in-

cludes any appliance with a pilot light. Because of

the danger or highly flammable liquids, do not use

gasoline or low-flash point solvents to clean them.

CAUTION

Immediately dry the bolts and nuts with com-

pressed air after cleaning.

Clean and dry the bolts and nuts completely.

www.zxforums.com

www.zxforums.com

www.zxforums.com

www.zxforums.com

www.zxforums.com

www.zxforums.com

www.zxforums.com