10-10 WHEELS/TIRES

Wheels (Rims)

Wheel Inspection

•

Raise the front/rear wheel off the ground.

Special Tools - Jack: 57001-1238

Jack Attachment: 57001-1608

•

Spin the wheel lightly, and check for roughness or binding.

If roughness or binding is found, replace the hub bearings.

•

Inspect the wheel for small cracks, dents, bending, or

warp.

If there is any damage to the wheel, replace the wheel.

•

Remove the wheel, and support it with the tire by the axle.

•

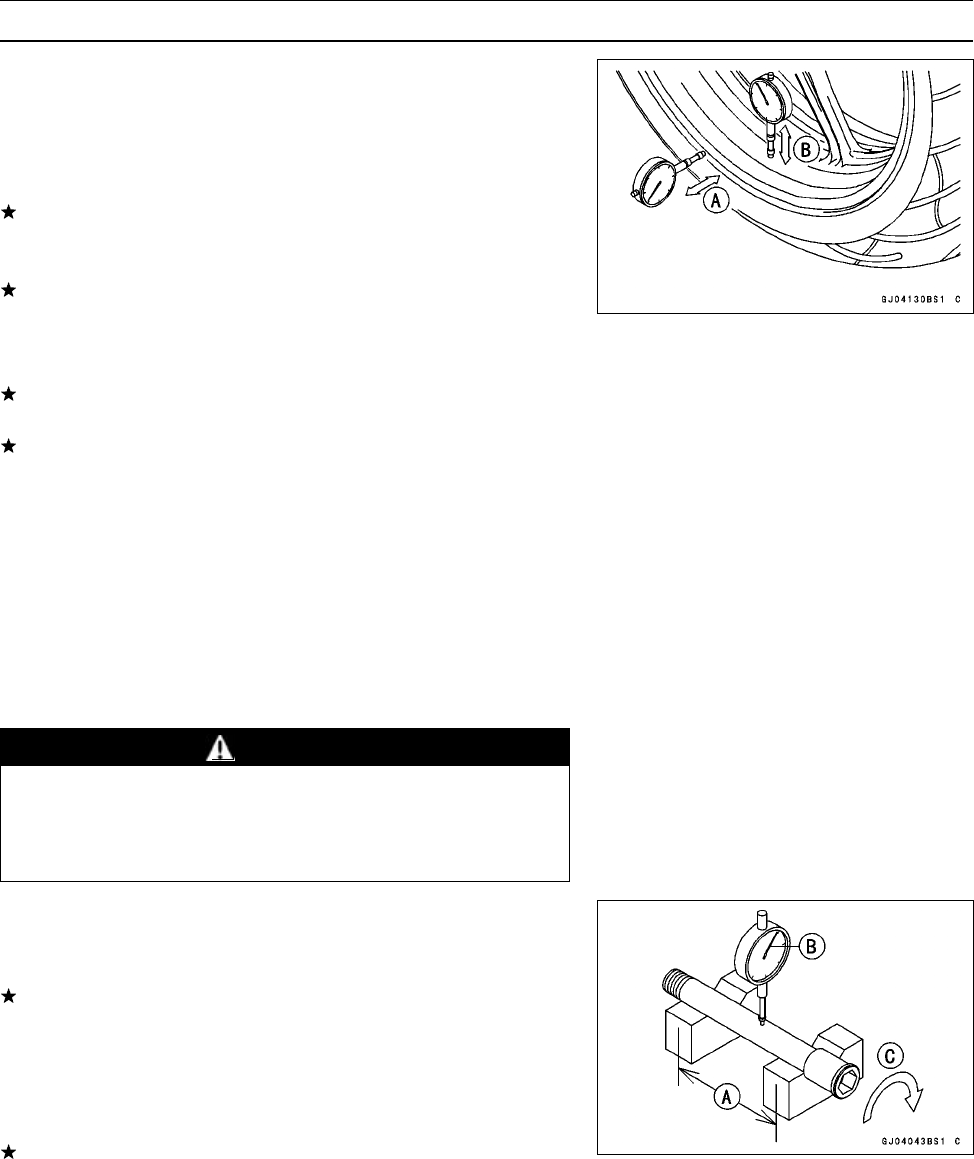

Measure the rim runout, axial [A] and radial [B], with a dial

gauge.

If rim runout exceeds the service limit, check the hub bear-

ings.

If the problem is not due to the bearings, replace the

wheel.

Rim Runout (with tire installed)

Standard:

Axial TIR 0.5 mm (0.02 in.) or less

Radial TIR 0.8 mm (0.03 in.) or less

Service Limit:

Axial TIR 1.0 mm (0.04 in.)

Radial TIR 1.0 mm (0.04 in.)

WARNING

Never attempt to repair a damaged wheel. If there

is any damage besides wheel bearings, the wheel

must be replaced to insure safe operational condi-

tion.

Axle Inspection

•

Remove the front and rear axles.

•

Visually inspect the front and rear axle for damages.

If the axle is damaged or bent, replace it.

•

Place the axle in V blocks that are 100 mm (3.94 in.) [A]

apart, and set a dial gauge [B] on the axle at a point

halfway between the blocks. Turn [C] the axle to mea-

sure the runout. The difference between the highest and

lowest dial readings is the amount of runout.

If axle runout exceeds the service limit, replace the axle.

Axle Runout/100 mm (3.94 in.)

Standard: TIR 0.03 mm (0.0012 in.) or less

Service Limit: TIR 0.2 mm (0.01 in.)

www.zxforums.com

www.zxforums.com

www.zxforums.com

www.zxforums.com

www.zxforums.com

www.zxforums.com

www.zxforums.com