17-80 ELECTRICAL SYSTEM

Actuator Control System

•

Support the vehicle on a stand or a jack so that the wheels

are off the ground.

•

Connect:

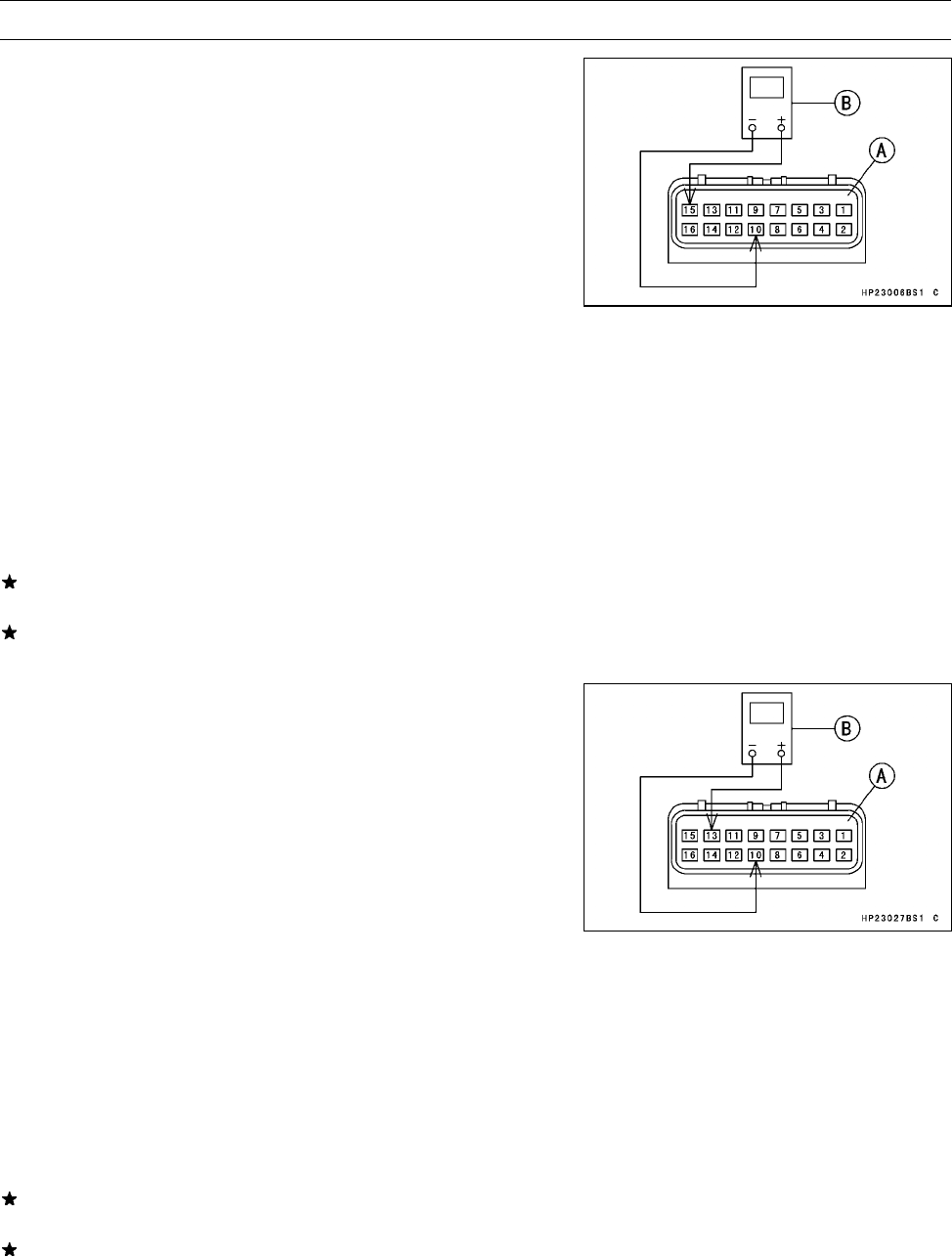

Controller Connector [A]

Hand Tester [B] (range: DC 25 V)

Tester (+ ) → Connector (W/R) Terminal [15]

Tester (–) → Connector (BK/Y) Terminal [10]

○

Install the needle adapters on the tester leads.

Special Tools - Hand Tester: 57001-1394

Needle Adapter Set: 57001-1457

•

Turn ON the ignition switch.

•

Spin a rear wheel as forward rotation.

•

After the wheels stop and one second elapses, turn O FF

the ignition switch.

•

After two seconds elapses, m easure the controller output

voltage for the engine brake actuator until the actuator

stops.

Controller O utput Voltage (to engine brake actuator)

Standard:

5 ∼ 12 V

If the reading is not standard, check the forward/reverse

detecting sensor.

If the forward/reverse detecting sensor is normal, replace

the actuator controller unit.

•

Support the vehicle on a stand or a jack so that the wheels

are off the ground.

•

Run the engine and shift to the 4WD position.

•

Stop the engine and turn OFF the ignition switch.

•

Connect:

Controller Connector [A]

Hand Tester [B] (range: DC 25 V)

Tester (+ ) → Connector (W/Y) Terminal [13]

Tester (–) → Connector (BK/Y) Terminal [10]

○

Install the needle adapters on the tester leads.

Special Tools - Hand Tester: 57001-1394

Needle Adapter Set: 57001-1457

•

Turn ON the ignition switch.

•

Shift to the 2WD position.

•

Measure the controller output voltage for the 2WD/4WD

actuator until the actuator stops.

Controller Output Voltage (to 2WD/4WD actuator)

Standard:

5 ∼ 12 V

If the reading is not standard, check the 2W D/4WD shift

switch.

If the 2WD/4WD shift switch is normal, replace the actu-

ator controller unit.