CRANKSHAFT/TRANSMISSION 10-27

Ball Bearing, Needle Bearing, and Oil S eal

Ball and Needle Bearing Replacement

CAUTION

Do not remove the ball or needle bearings unless it

is necessary. Removal may damage them.

•

Using a press or puller, remove the ball bearing and/or

three needle bearings.

NOTE

○

In the absence of the above mentioned tools, satisfac-

tory results may be obtained by heating the case to ap-

proximately 93°C (200°F) max., and tapping the bearing

in or out.

CAUTION

Do not heat the case w ith a torch. This will warp the

case. Soak the case in oil and heat the oil.

•

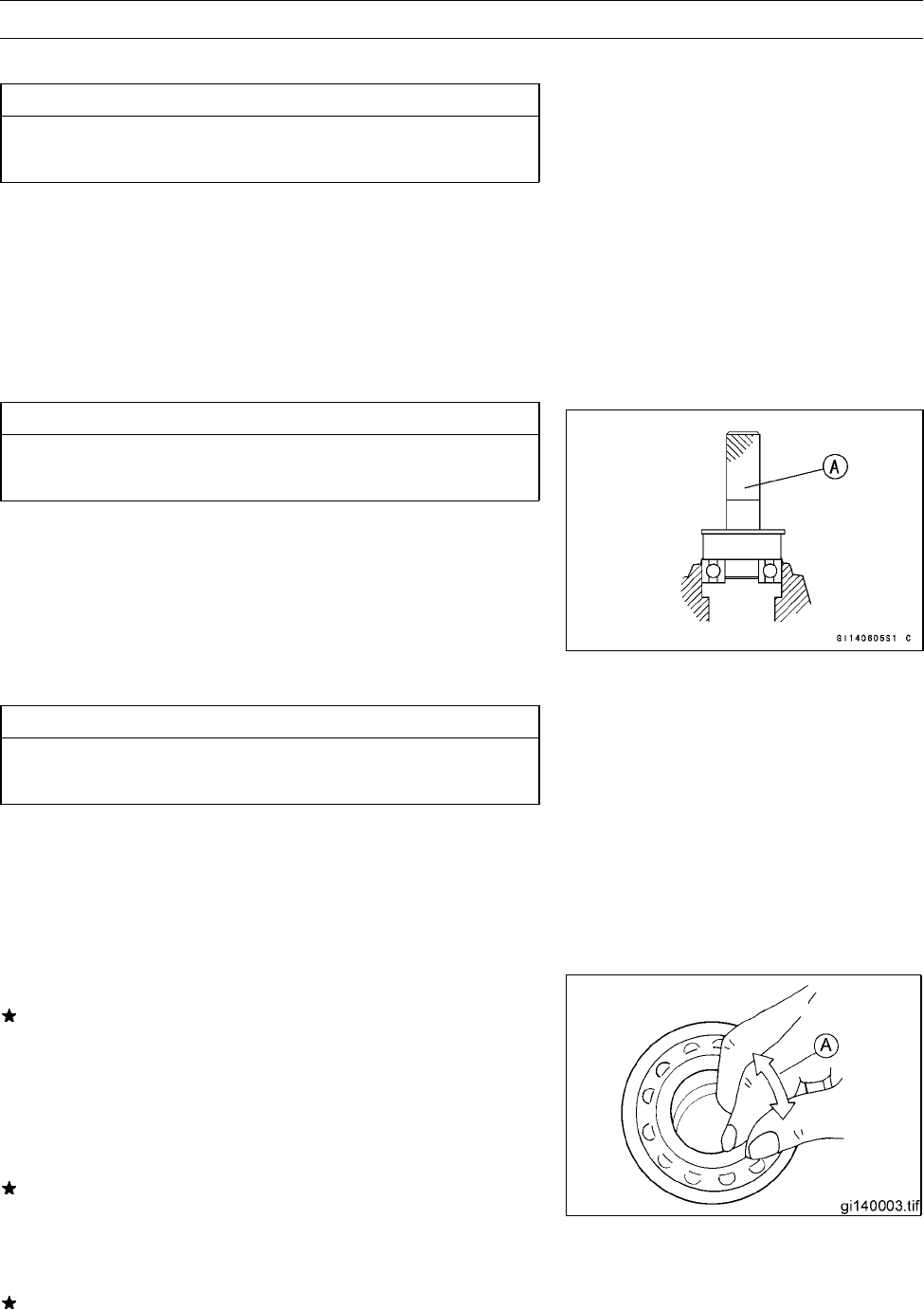

Using a press and the bearing driver set [A], install the

new ball bearing until it stops at the bottom of its housing.

○

Three new needle bearings must be pressed into the

crankcase so that the end is flush with the end of the

hole.

Special Tool - Bearing Driver Set: 57001-1129

Ball and Needle Bearing Wear

CAUTION

Do not remove the bearings for inspection. Re-

moval may damage them.

•

Check the ball bearings.

○

Since the ball bearings are made to extremely close toler-

ances, the wear must be judged by feel rather than mea-

surement. Clean each bearing in a high-flash point sol-

vent, dry it (do not spin the bearing while it is dry), and oil

it with engine oil.

○

Spin [A] the bearing by hand to check its condition.

If the bearing is noisy, does not spin smoothly, or has any

rough spots, replace it.

•

Check the needle bearings.

○

The rollers in a needle bearing normally wear very little,

and wear is difficult to measure. Instead of measuring,

inspect the bearing for abrasion, color change, or other

damage.

If there is any doubt as to the condition of a needle bear-

ing, replace it.

Oil Seal Inspection

•

Inspect the oil seals.

Replace it if the lips are misshapen, discolored (indicating

that the rubber has deteriorated), hardened or otherwise

damaged.