12-46 FIN AL DRIVE

Front Final Gear Case

Pinion Gear Unit Assembly

○

The pinion gear and ring gear are lapped as a set in the

factory to get the best tooth contact. They must be re-

placed as a set.

•

Visually inspect the bearing for abrasion, color change, or

other damage.

If there is any doubt as to the condition of a bearing, re-

place the bearing.

•

Be sure to check and adjust the bevel gear backlash and

tooth contact, when any of the backlash-related parts are

replaced (see Front Final Bevel Gear Adjustment).

•

Press the bearing on the pinion gear until it is bottomed.

•

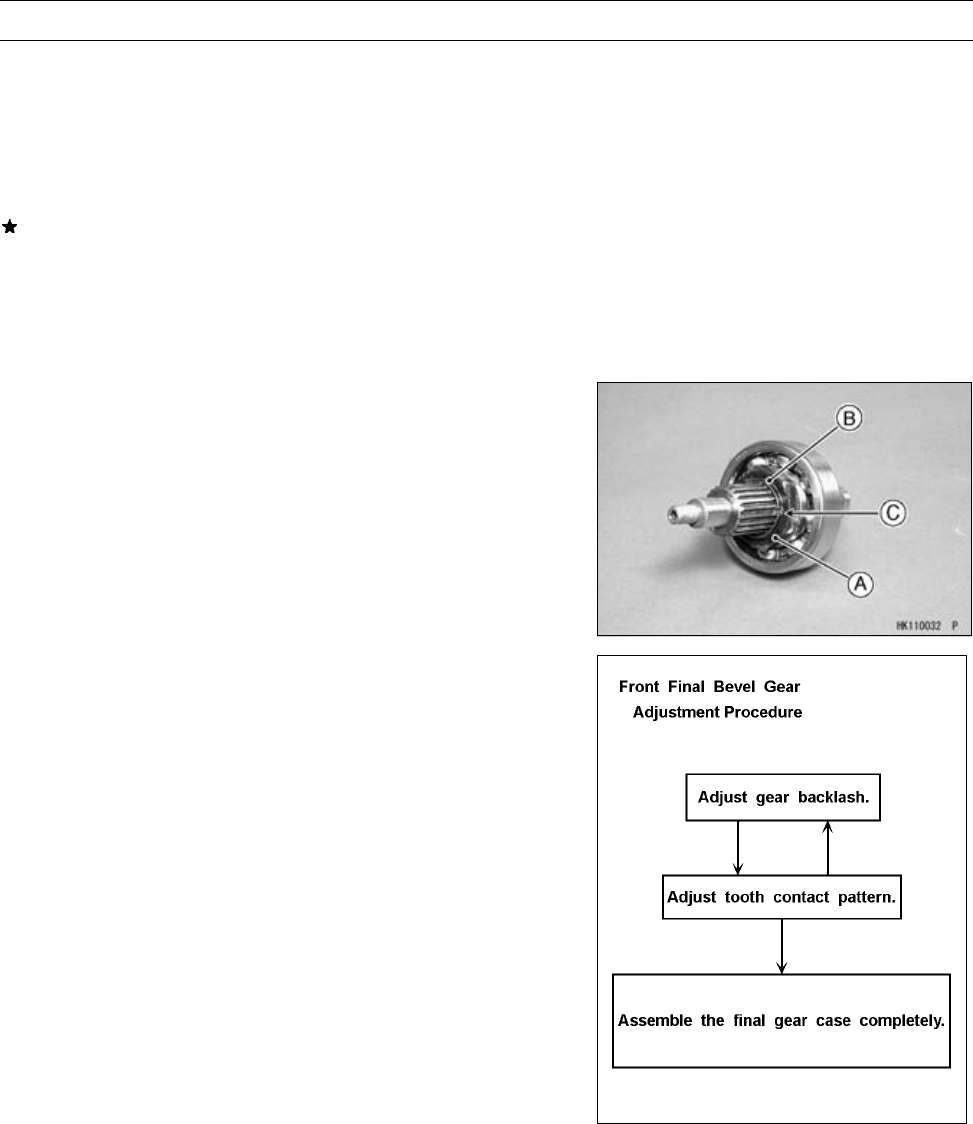

Install the pinion gear bearing holder nut [A] so that the

projection [B] faces outward.

•

Tighten:

Special Tool - Pinion Gear Holder, m1.0: 57001-1485

Torque - Pinion Gear Bearing Holder Nut: 127 N·m (13

kgf·m, 94 ft·lb)

•

Stake [C] the nut with a punch at three positions to secure

it.

Front Final Bevel G ear Adjustment

The backlash (distance one gear will move back and forth

without moving the mate gear) and tooth contact pattern

of the bevel gears must be correct to prevent the gears from

making noise and being damaged.

Above two adjustments are of critical importance and

must be carried out following t he correct sequence and

method.

•

When any one of the backlash-related parts are replaced,

check and adjust the bevel gear backlash, and tooth con-

tact by replacing shims.

○

The amount of backlash is influenced by the ring gear

position more than by the pinion gear position.

○

Tooth contact location is influenced by the pinion gear po-

sition more than by the ring gear position.