17-48 ELECTRICAL SYSTEM

Electric Starter System

•

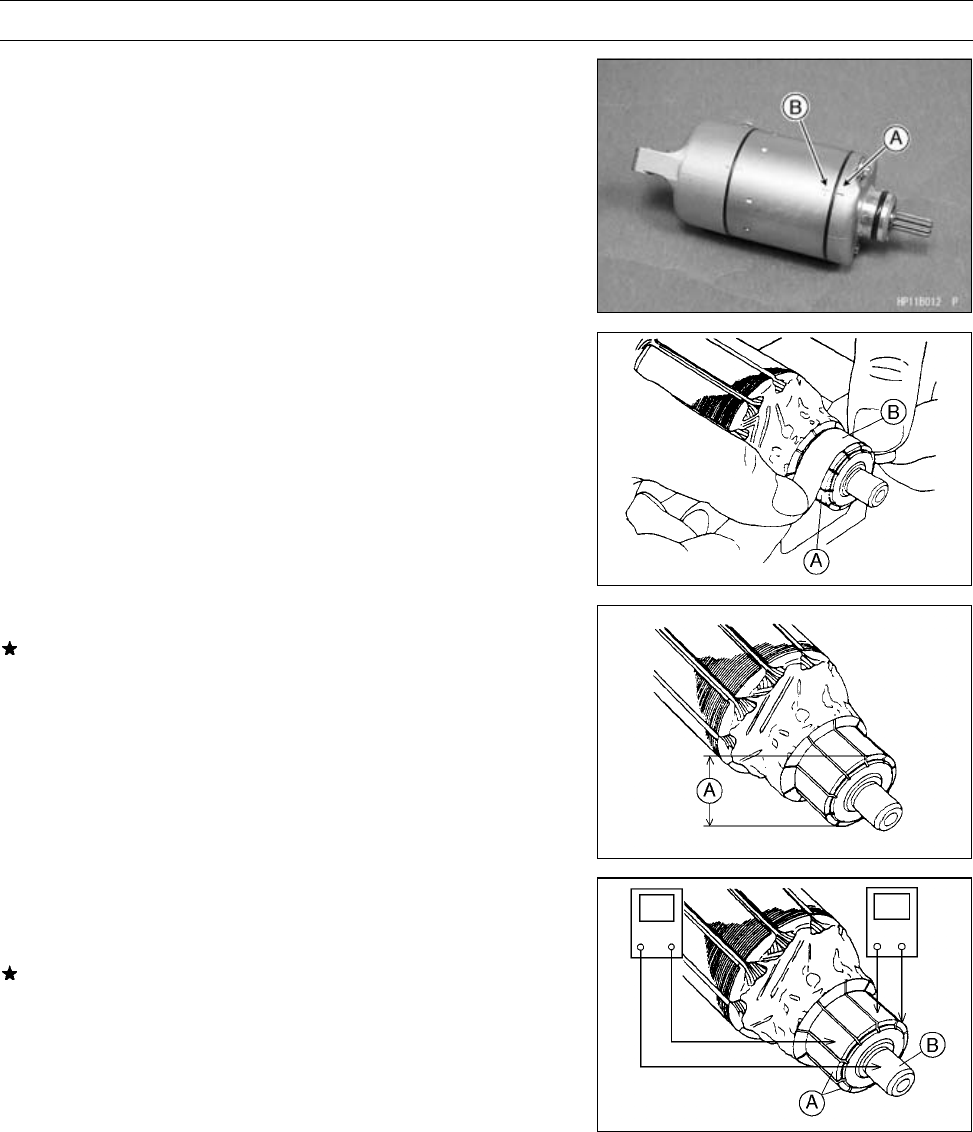

Align the mark [A] on the left end cover with the mark [B]

on the yoke.

•

Tighten:

To rque - Starter Motor Bolts: 4.9 N·m (0.50 kgf·m, 43 in·l b)

Commutator Cleaning/Inspection

•

Smooth the commutator surface [A] if necessary with fine

emery cloth [B], and clean out the grooves.

•

Measure the diameter [A] of the commutator.

Replace the starter motor with a new one if the commu-

tator diameter is less than the service limit.

Commutator Diameter

Standard: 28 mm (1.10 in.)

Service Limit: 27 mm (1.06 in.)

Armature Inspection

•

Using the × 1 Ω range, measure the resistance between

any two commutator segments [ A].

If there is a high resistance or no reading (∞) between

any two segments, a winding is open. Replace the starter

motor.

•

Using the highest range, measure the resistance between

the segments and the shaft [B].

•

If there is any reading at all, the armature has a short.

Replace the starter motor.

NOTE

○

Even if the foregoing checks show the armature t o be

good, it may be defective in some manner not readily

detectable with the hand tester. I f all other starter motor

and starter motor circuit components check good, but

the starter motor still does not turn over or only turns

over weakly, replace the starter motor with a new one.