3·64

ENGINE

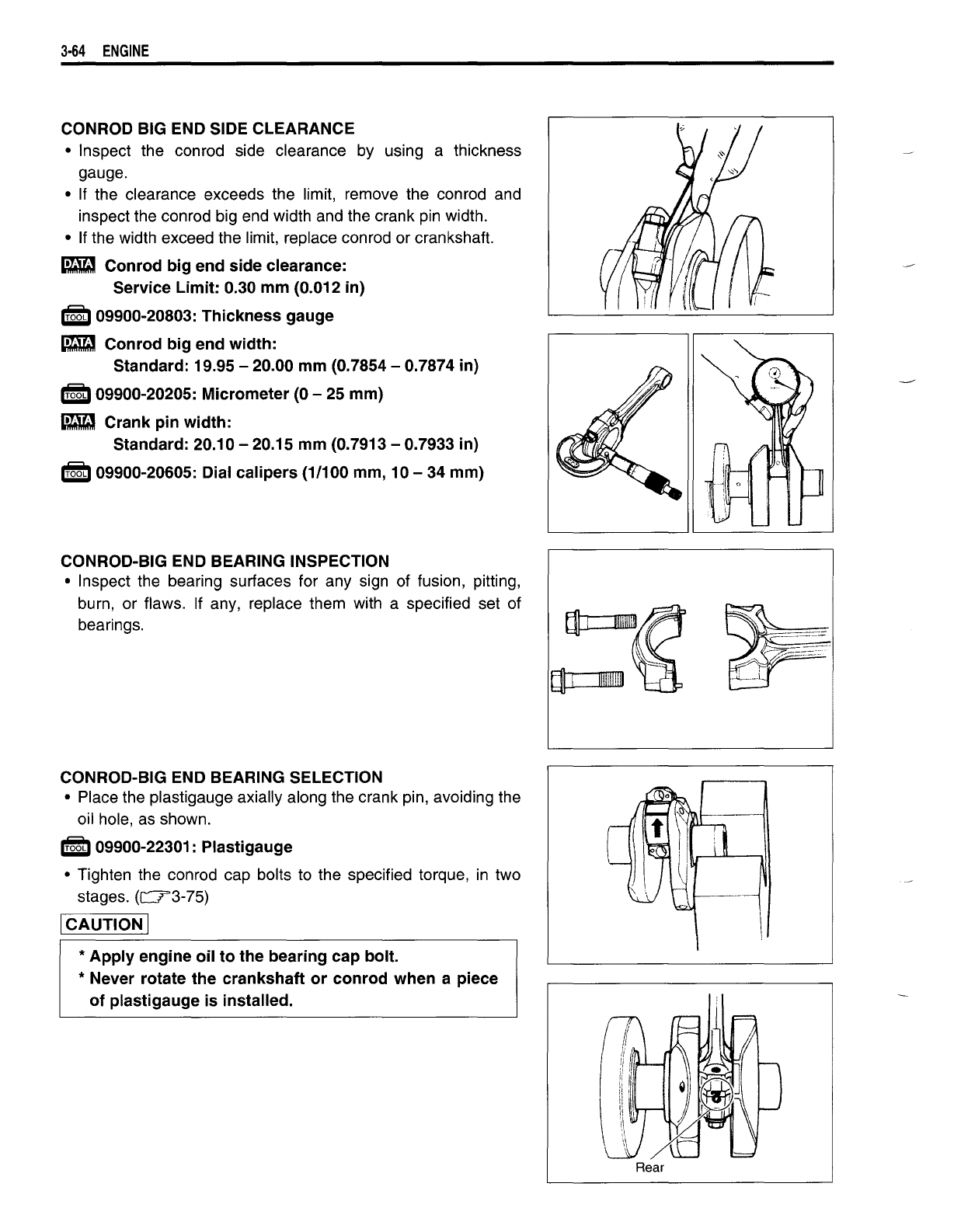

CONROD BIG END SIDE CLEARANCE

• Inspect the conrad side clearance by using a thickness

gauge.

• If the clearance exceeds the limit, remove the conrad and

inspect the conrad big end width and the crank pin width.

• If the width exceed the limit, replace conrad or crankshaft.

_ Conrod big

end

side clearance:

Service

Limit:

0.30 mm (0.012 in)

IT'OOti

09900-20803:

Thickness

gauge

_ Conrod

big

end

width:

Standard: 19.95 - 20.00 mm (0.7854 - 0.7874 in)

lroot,

09900-20205: Micrometer (0 - 25 mm)

_ Crank pin

width:

Standard: 20.10 - 20.15 mm (0.7913 - 0.7933 in)

IT'OOt,

09900-20605: Dial calipers (1/100 mm, 10 - 34 mm)

CONROD-BIG END BEARING INSPECTION

• Inspect the bearing surfaces for any sign of fusion, pitting,

burn, or flaws. If any, replace them with a specified set of

bearings.

Ilmil~

111111I1i11~

CONROD-BIG END BEARING SELECTION

• Place the plastigauge axially along the crank pin, avoiding the

oil hole, as shown.

l';!OOti

09900-22301: Plastigauge

• Tighten the conrad cap bolts to the specified torque, in two

stages.

(CT'3-75)

ICAUTION I

*

Apply

engine

oil

to

the

bearing

cap

bolt.

* Never rotate

the

crankshaft

or

conrod

when a piece

of

plastigauge is installed.

Rear