CRANKSHAFT AND CONROD

CRANKSHAFT RUNOUT

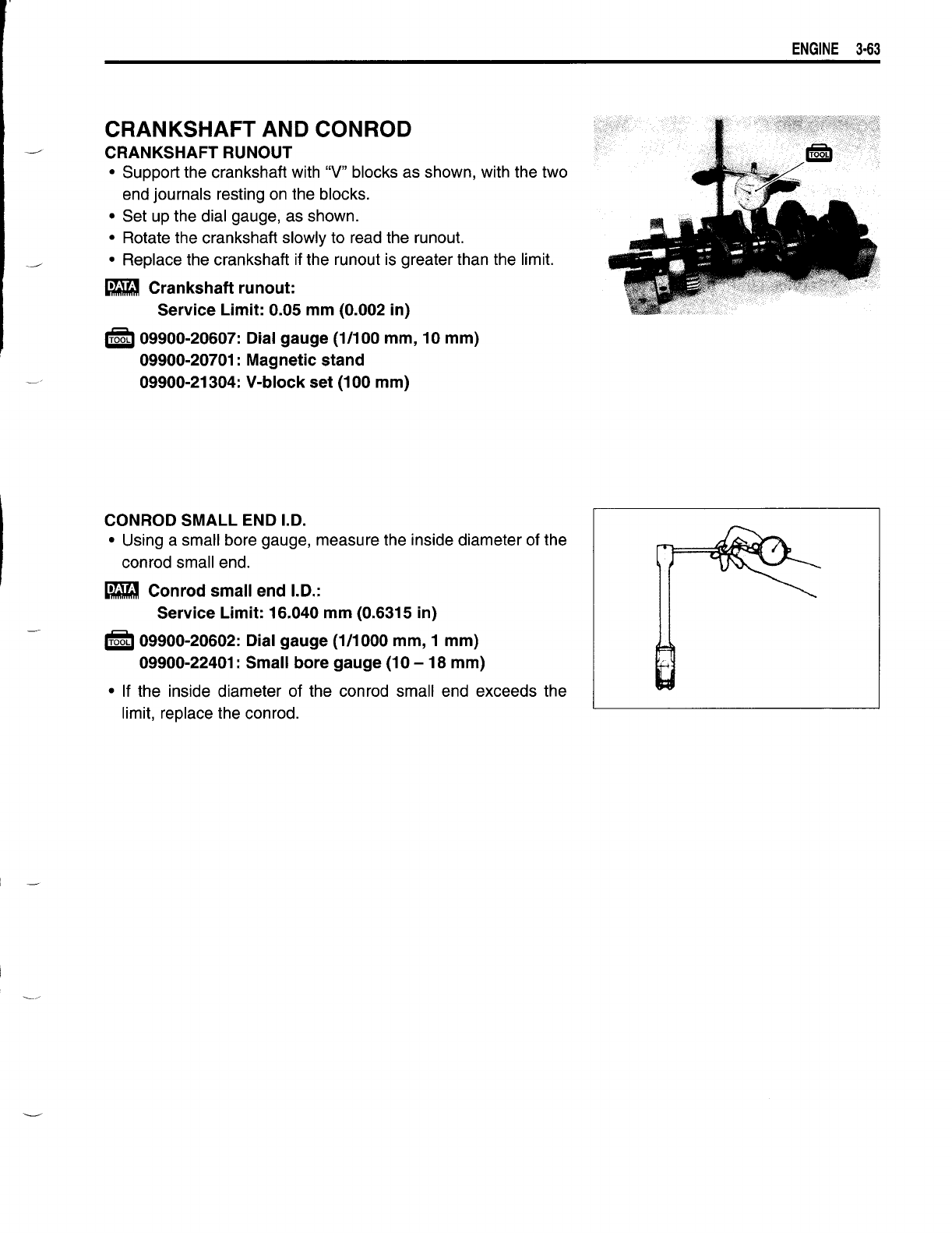

• Support the crankshaft with "V" blocks as shown, with the two

end journals resting on the blocks.

• Set up the dial gauge, as shown.

• Rotate the crankshaft slowly to read the runout.

• Replace the crankshaft if the runout is greater than the limit.

_ Crankshaft runout:

Service Limit:

0.05 mm (0.002 in)

'TiKI

09900-20607: Dial gauge (1/100 mm, 10 mm)

09900-20701: Magnetic stand

09900-21304: V-block set (100 mm)

CONROD SMALL END I.D.

• Using a small bore gauge, measure the inside diameter of the

conrad small end.

_ Conrad small end I.D.:

Service Limit:

16.040 mm (0.6315 in)

,KiOti

09900-20602: Dial gauge (1/1000 mm, 1 mm)

09900-22401: Small bore gauge

(10-

18 mm)

• If the inside diameter of the conrad small end exceeds the

limit, replace the conrad.

ENGINE

3·63