CHASSIS 8-91

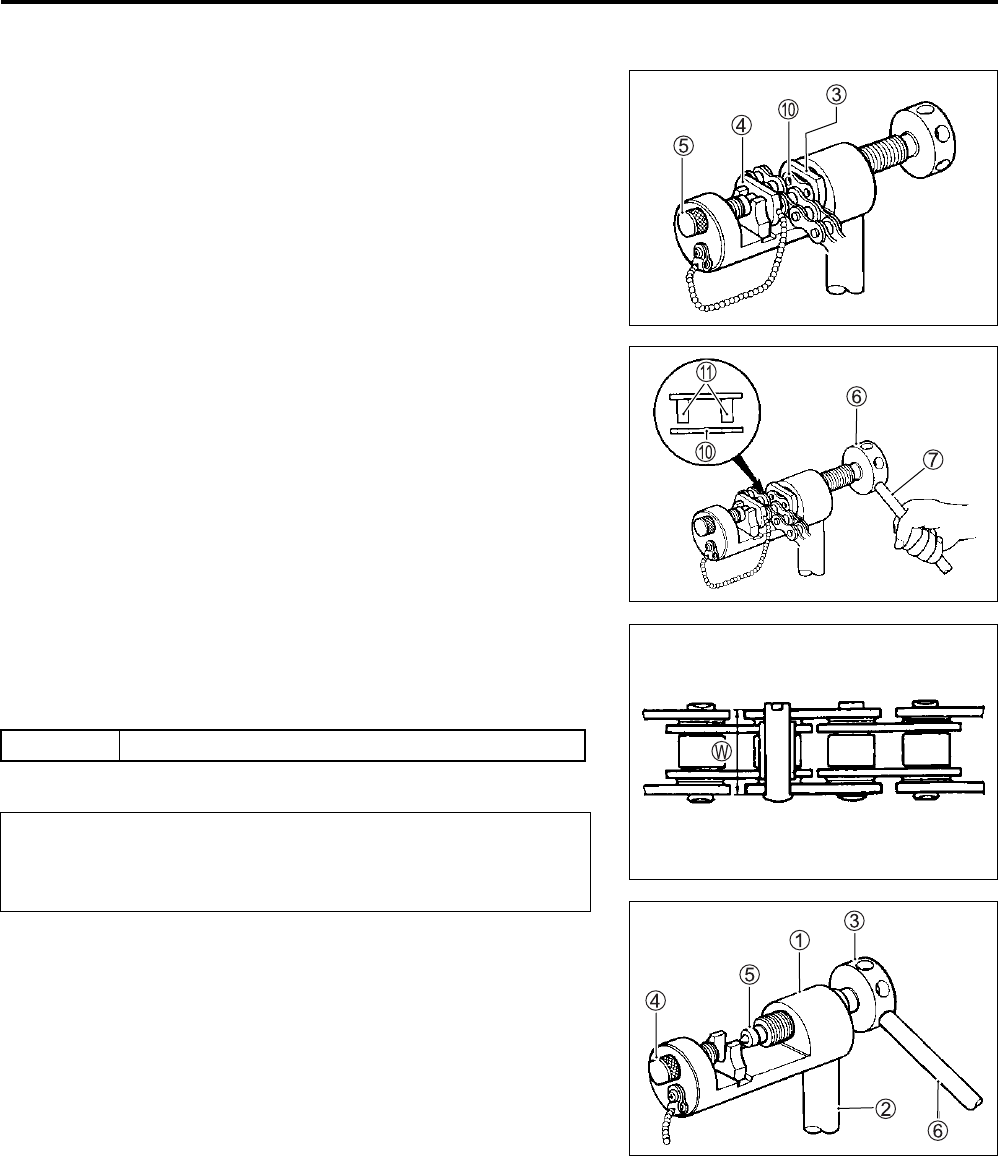

• Apply grease on the recessed portion of the joint plate holder

3 and set the joint plate 0.

NOTE:

When positioning the joint plate

0

on the tool, its stamp mark

must face the joint plate holder

3

side.

• Set the drive chain on the tool as illustrated and turn in the

adjuster bolt 5 to secure the wedge holder & wedge pin 4.

• Turn in the pressure bolt “A” 6 and align two joint pins A

properly with the respective holes of the joint plate 0

• Turn in the pressure bolt “A” 6 further using the bar 7 to

press the joint plate over the joint pins.

• Continue pressing the joint plate until the distance between

the two joint plates come to the specification.

Joint plate distance specification W

JOINT PIN STAKING

• Set up the special tool as shown in the illustration.

1 Tool body

2 Grip handle

3 Pressure bolt “A”

4 Adjuster bolt (without hole)

5 Staking pin (stowed inside grip handle behind rubber cap)

6 Bar

NOTE:

Before staking the joint pin, apply a small quantity of grease to

the staking pin

5

.

RK 18.6 – 18.9 mm (0.732 – 0.744 in)

Should pressing of the joint plate be made excessively

beyond the specified dimension, the work should be

redone using the new joint parts.