ENGINE 3-61

CRANKSHAFT AND CONROD

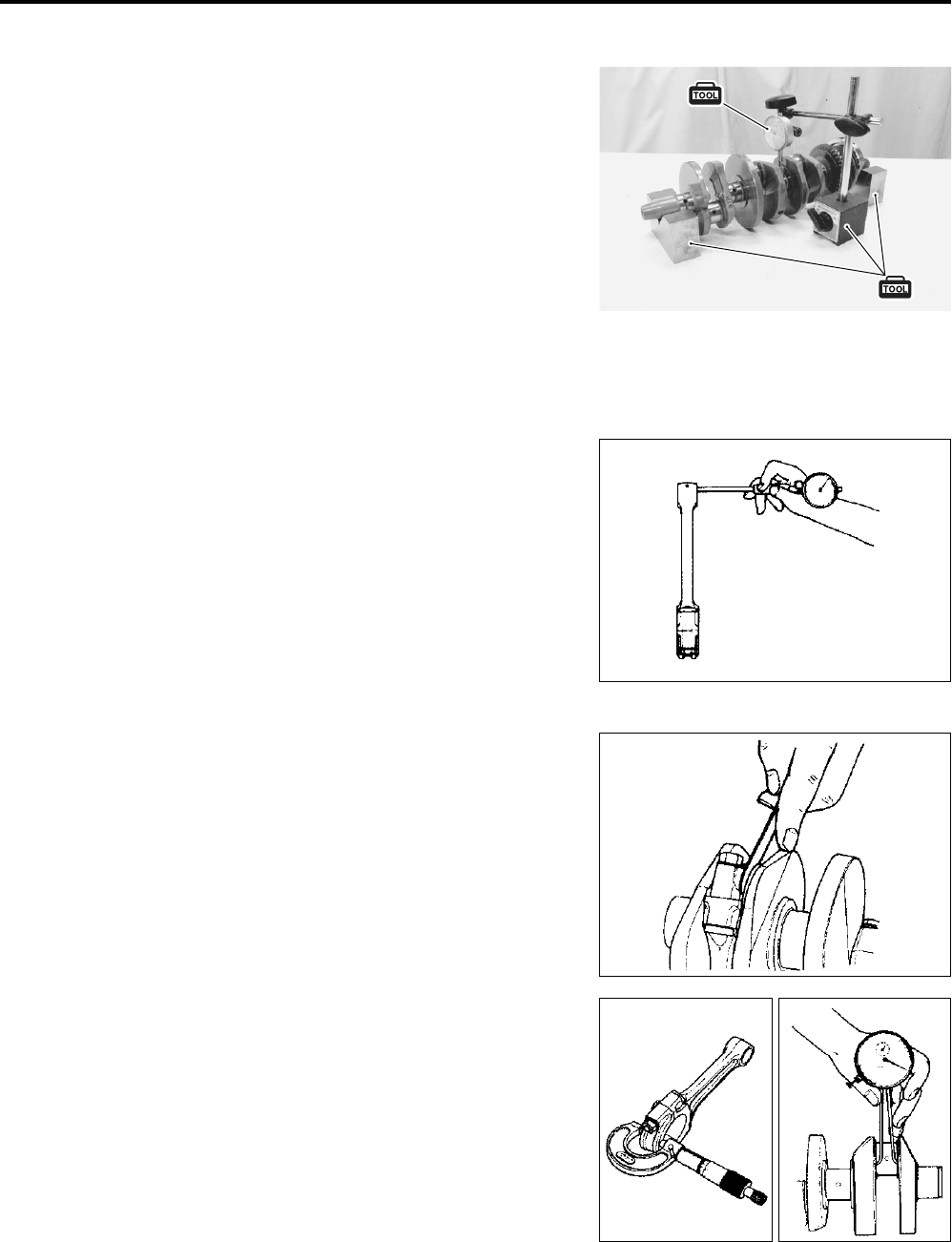

CRANKSHAFT RUNOUT

• Support the crankshaft with V-blocks as shown, with the two

end journals resting on the blocks.

• Set up the dial gauge, as shown.

• Rotate the crankshaft slowly to read the runout.

• Replace the crankshaft if the runout is greater than the limit.

Crankshaft runout:

Service Limit: 0.05 mm (0.002 in)

09900-20607: Dial gauge (1/100 mm, 10 mm)

09900-20701: Magnetic stand

09900-21304: V-block set (100 mm)

CONROD SMALL END I.D.

• Using a small bore gauge, measure the inside diameter of the

conrod small end.

Conrod small end I.D.:

Service Limit: 14.040 mm (0.5528 in)

09900-20602: Dial gauge (1/1000 mm, 1 mm)

09900-22401: Small bore gauge (10 – 18 mm)

• If the inside diameter of the conrod small end exceeds the

limit, replace the conrod.

CONROD BIG END SIDE CLEARANCE

• Inspect the conrod side clearance by using a thickness

gauge.

• If the clearance exceeds the limit, remove the conrod and

inspect the conrod big end width and the crank pin width.

• If the width exceed the limit, replace conrod or crankshaft.

Conrod big end side clearance:

Service Limit: 0.30 mm (0.012 in)

09900-20803: Thickness gauge

Conrod big end width:

Standard: 19.95 – 20.00 mm (0.7854 – 0.7874 in)

09900-20205: Micrometer (0 – 25 mm)

Crank pin width:

Standard: 20.10 – 20.15 mm (0.7913 – 0.7933 in)

09900-20605: Dial calipers (1/100 mm, 10 – 34 mm)