FI SYSTEM DIAGNOSIS 4-41

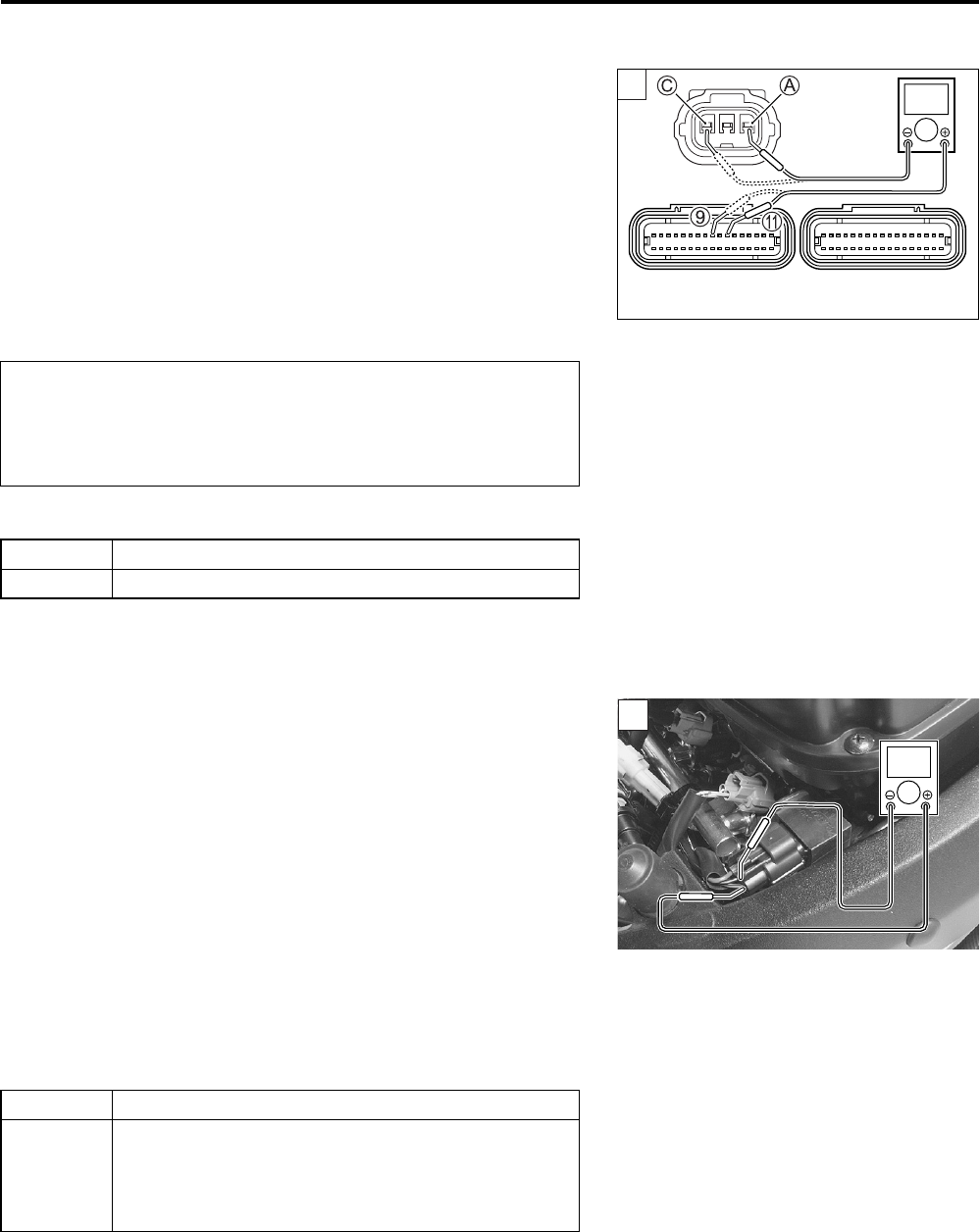

7) Disconnect the ECM coupler.

8) Check the continuity between R wire A and terminal A.

9) Also, check the continuity between G/B wire C and terminal

9.

IAPS lead wire continuity:

Continuity ()

09900-25008: Multi-circuit tester set

09900-25009: Needle pointed probe set

Tester knob indication: Continuity test ()

Is the continuity OK?

10)After repairing the trouble, clear the DTC using SDS tool.

(4-27)

Step 2

1) Connect the IAP sensor coupler and ECM coupler.

2) Insert the needle pointed probes to the lead wire coupler.

3) Start the engine at idle speed and measure the IAP sensor

output voltage at the wire side coupler (between G/B and

B/Br wires).

IAP sensor output voltage: Approx. 2.7 V at idle speed

(+ G/B – - B/Br)

09900-25008: Multi-circuit tester set

09900-25009: Needle pointed probe set

Tester knob indication: Voltage ()

Is the voltage OK?

4) After repairing the trouble, clear the DTC using SDS tool.

(4-27)

When using the multi-circuit tester, do not storongly

touch the terminal of the ECM coupler with a needle

pointed tester probe to prevent the terminal damage

or terminal bend.

YES Go to Step 1 (4-38) and go to Step 2.

NO R or G/B wire open, or G/B wire shorted to ground

YES Go to Step 3.

NO

• Check the vacuum hose for crack or damage.

• Open or short circuit in the G/B wire

• If vacuum hose and wire are OK, replace the

IAP sensor with a new one.

1

!

(Black)

(Gray)

ECM couplers (Harness side)

2

V