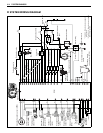

FI SYSTEM DIAGNOSIS 4-11

COMPENSATION OF INJECTION TIME (VOLUME)

The following different signals are output from the respective sensors for compensation of the fuel injection

time (volume).

INJECTION STOP CONTROL

SIGNAL DESCRIPTION

ATMOSPHERIC PRESSURE SENSOR

SIGNAL

When atmospheric pressure is low, the sensor sends the

signal to the ECM and reduce the injection time (volume).

ENGINE COOLANT TEMPERATURE SEN-

SOR SIGNAL

When engine coolant temperature is low, injection time (vol-

ume) is increased.

INTAKE AIR TEMPERATURE SENSOR

SIGNAL

When intake air temperature is low, injection time (volume)

is increased.

HEATED OXYGEN SENSOR SIGNAL

(For E-02, 19)

Air/fuel ratio is compensated to the theoretical ratio from

density of oxygen in exhaust gasses. The compensation

occurs in such a way that more fuel is supplied if detected

air/fuel ratio is lean and less fuel is supplied if it is rich.

BATTERY VOLTAGE SIGNAL ECM operates on the battery voltage and at the same time,

it monitors the voltage signal for compensation of the fuel

injection time (volume). A longer injection time is needed to

adjust injection volume in the case of low voltage.

ENGINE RPM SIGNAL At high speed, the injection time (volume) is increased. This

is the compensation of the SRAD.

STARTING SIGNAL When starting engine, additional fuel is injected during

cranking engine.

ACCELERATION SIGNAL/

DECELERATION SIGNAL

During acceleration, the fuel injection time (volume) is

increased in accordance with the throttle opening speed and

engine rpm. During deceleration, the fuel injection time (vol-

ume) is decreased.

SIGNAL DESCRIPTION

TIP-OVER SENSOR SIGNAL

(FUEL SHUT-OFF)

When the motorcycle tips over, the tip-over sensor sends a

signal to the ECM. Then, this signal cuts OFF current sup-

plied to the fuel pump, fuel injectors and ignition coils.

OVER-REV. LIMITER SIGNAL The fuel injectors stop operation when engine rpm reaches

rev. limit rpm.