2-30 PERIODIC MAINTENANCE

Periodic Maintenance Procedures

If it does not, adjust and inspect the brake light switch.

•

While holding the switch body, turn the adjusting nut [A]

to adjust the switch.

CAUTION

To avoid damaging the electrical connections in-

side the switch, be sure that the switch body does

not turn during adjustment.

•

Remove the right side cover (see Frame chapter).

•

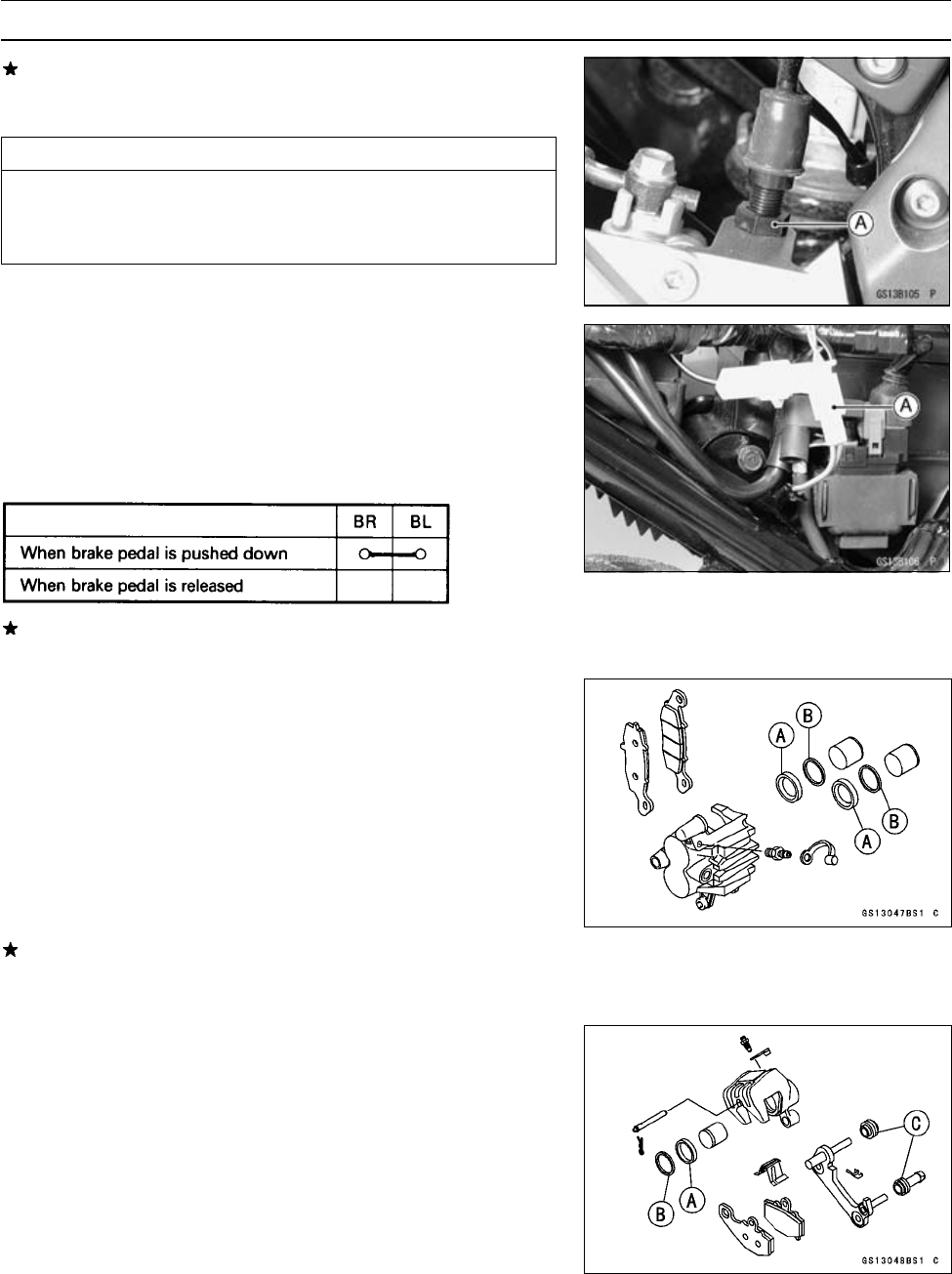

Disconnect the connector [A].

•

Using a hand tester, inspect to see that only t he connec-

tion shown in the table have continuity (about zero ohms).

Special Tool - H and Tester: 57001–1394

Rear Brake Light Switch Connections:

If the switch has an open or short, replace it with a new

one.

Caliper Fluid Seal Damage

The fluid seals [A] around the piston maintain the proper

pad/disc clearance. If the seals are not satisfactory, pad

wear will increase, and constant pad drag on the disc will

raise brake and brake fluid temperature.

•

Remove the calipers (see Brakes chapter).

•

Replace the fluid seals under any of the following condi-

tions; (a) fluid leakage around the pad; (b) brakes over-

heat (c) there is a large difference in inner and outer pad

wear; (d) the seal is stuck to the piston.

If the fluid seal is replaced, replace the dust seals [ B] as

well. Also, replace all seals every other time the pads are

changed.

Caliper Dust Seal/Friction Boot Damage

•

Remove the calipers (see Brakes chapter).

•

Check that the dust seals [B] and friction boots [C] are not

cracked, worn, swollen, or otherwise damaged.

•

If they show any damage, remove the caliper bracket and

replace them.