PERIODIC MAINTENANCE 2-27

Periodic M aintenance Procedures

Final Drive

Drive Chain Slack Inspection

NOTE

○

Check the slack with the m otorcycle setting on its side

stand.

○

Clean the chain if it is dirty, and lubricate it if it appears

dry.

•

Check the wheel alignment (see Wheel Alignment Inspec-

tion).

•

Rotate the rear w heel to find the position where the chain

is tightest.

•

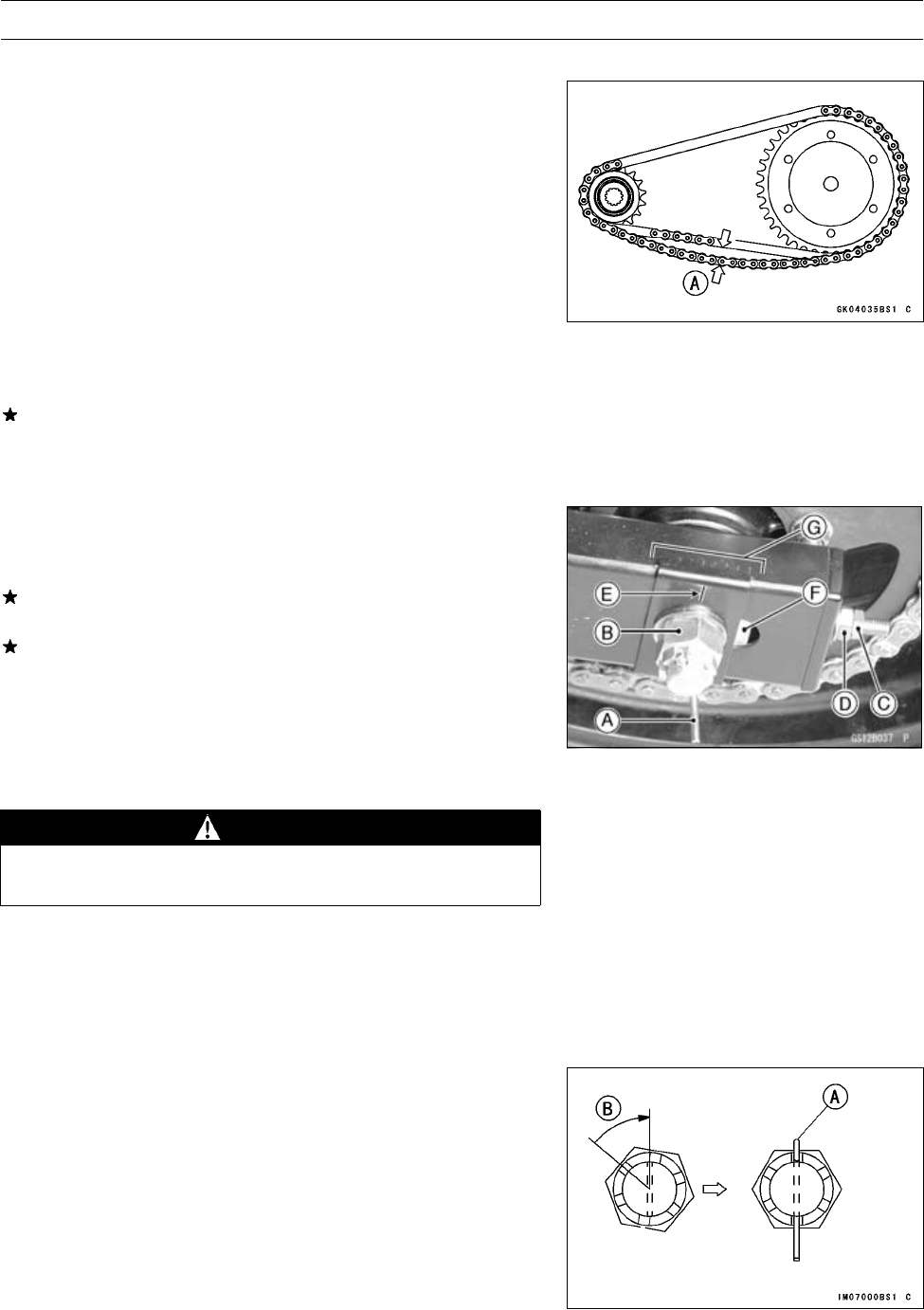

Measure the vertical movem ent (chain slack) [A] midway

between the sprockets.

If the chain slack exceeds the standard, adjust it.

Chain Slack

Standard: 2 5 ∼ 35 mm (1.0 ∼ 1.4 in.)

Drive Chain Slack Adjustment

•

Remove the cotter pin [A], and loosen the axle nut [B].

•

Loosen the both chain adjuster locknuts [C].

If the chain is too loose, turn out the left and right chain

adjuster [D] evenly.

If the chain is too tight, turn in the left and right chain

adjusters evenly, and kick the wheel forward.

•

Turn both chain adjusters evenly until the drive chain has

the correct amount of slack. To keep the chain and w heel

properly aligned, the notch [E] on the left wheel alignment

indicator [F] should align with the same swingarm mark or

position [G] that the right indicator notch aligns with.

WARNING

Misalignment of the wheel w ill result in abnormal

wear and may result in an unsafe riding condition.

•

Tighten both chain adjuster locknuts securely.

•

Tighten the axle nut.

Torque - Rear Axle Nut: 108 N·m (11 kgf·m, 80 ft·lb)

•

Turn the wheel, measure the chain slack again at the tight-

est position, and readjust if necessary.

•

Insert a new cotter pin [A].

NOTE

○

When inserting the cotter pin, if the slots in the nut do

not align with the cotter pin hole in the axle, tighten the

nut clockwise [B] up to next alignment.

○

It should be within 30 degree.

○

Loosen once and tighten again when the slot goes past

the nearest hole.