ENGINE TOP E ND 5-31

Cylinder, Pistons

Piston Ring, Piston Ring Groove Wear

•

Check for uneven groove wear by inspecting the ring seat-

ing.

The rings should fit perfectly parallel to groove surfaces.

If not, replace the piston and all the piston rings.

•

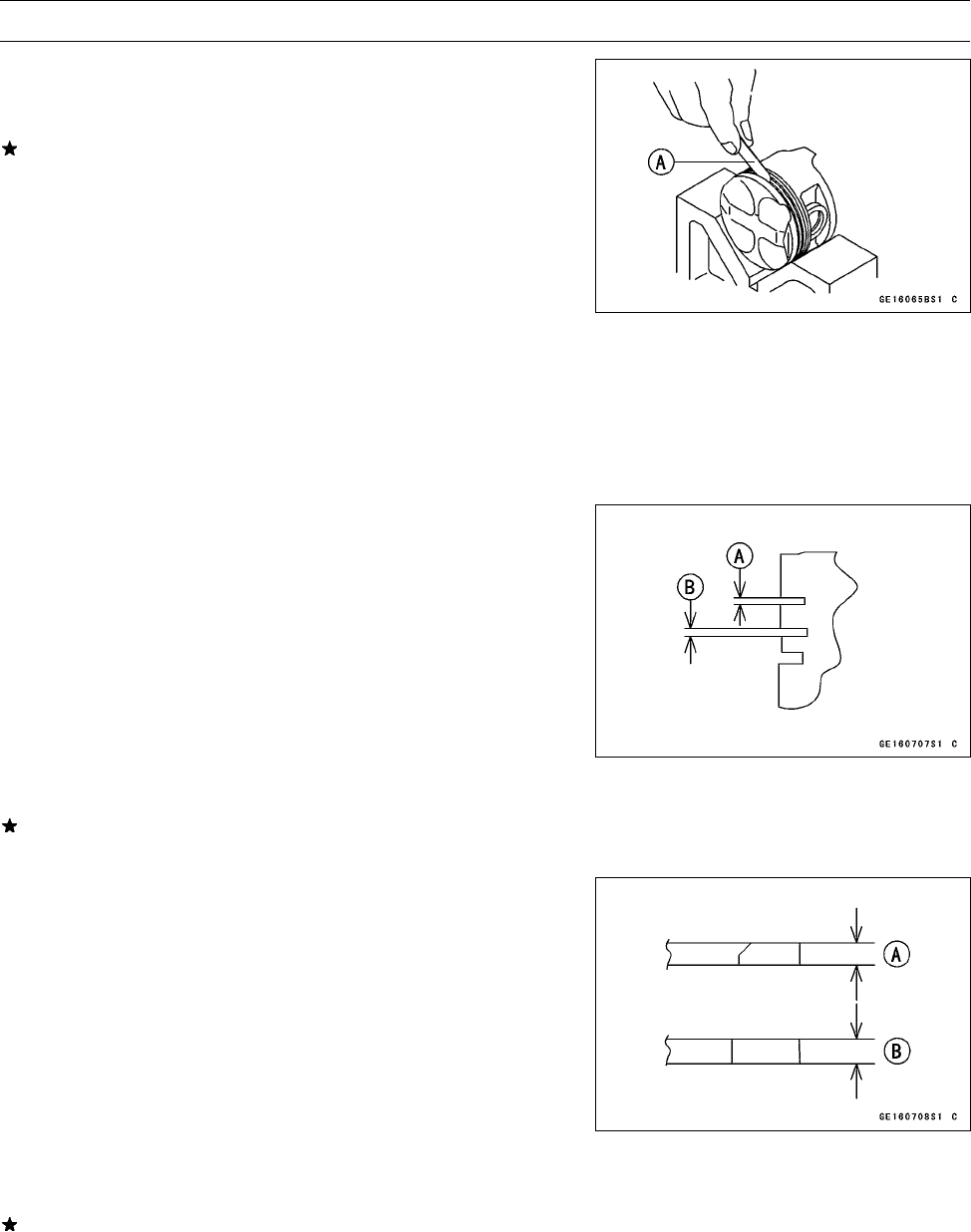

With the piston r ings in their grooves, make several mea-

surements with a thickness gauge [A] to determine piston

ring/groove clearance.

Piston Ring/Groove Clearance

Top

Standard: 0.04 ∼ 0.08 mm (0.0016 ∼ 0.0031 in.)

Service Limit: 0.18 m m (0.007 1 in.)

Second

Standard: 0.02 ∼ 0.06 mm (0.0008 ∼ 0.0024 in.)

Service Limit: 0.16 m m (0.006 3 in.)

PistonRingGrooveWidth

•

Measure the piston ring groove width.

○

Use a vernier caliper at several points around the piston.

Piston Ring Groove Width

Top [A]

Standard: 0.83 ∼ 0.85 mm (0.0327 ∼ 0.0335 in.)

Service Limit: 0.93 mm (0.037 in.)

Second [B]

Standard: 0.81 ∼ 0.83 mm (0.0319 ∼ 0.0327 in.)

Service Limit: 0.91 mm (0.036 in.)

If the width of any of the two grooves is wider than the

service limit at any point, replace the piston.

Piston Ring Thickness

•

Measure the piston ring thickness.

○

Use the micrometer to measure at s everal points around

the ring.

Piston Ring Thickness

Top [A]

Standard: 0.77 ∼ 0.79 mm (0.0303 ∼ 0.0311 in.)

Service Limit: 0.70 mm (0.028 in.)

Second [B]

Standard: 0.77 ∼ 0.79 mm (0.0303 ∼ 0.0311 in.)

Service Limit: 0.70 mm (0.028 in.)

If any of the measurements is less than the service limit

on either of the rings, replace all the rings.

NOTE

○

When using new rings in a used piston, check for un-

even groove wear. The rings should fit perfectly parallel

to the groove sides. If not, replace the piston.