11 -12 FINAL DRIVE

Sprocket, Coupling

•

Replace the grease seal with a new one.

•

Press in the grease seal so that the seal surface is flush

with the end of the hole.

○

Apply high temperature grease to the grease seal lips.

Special Tool - Bearing Driver Set: 57001–1129

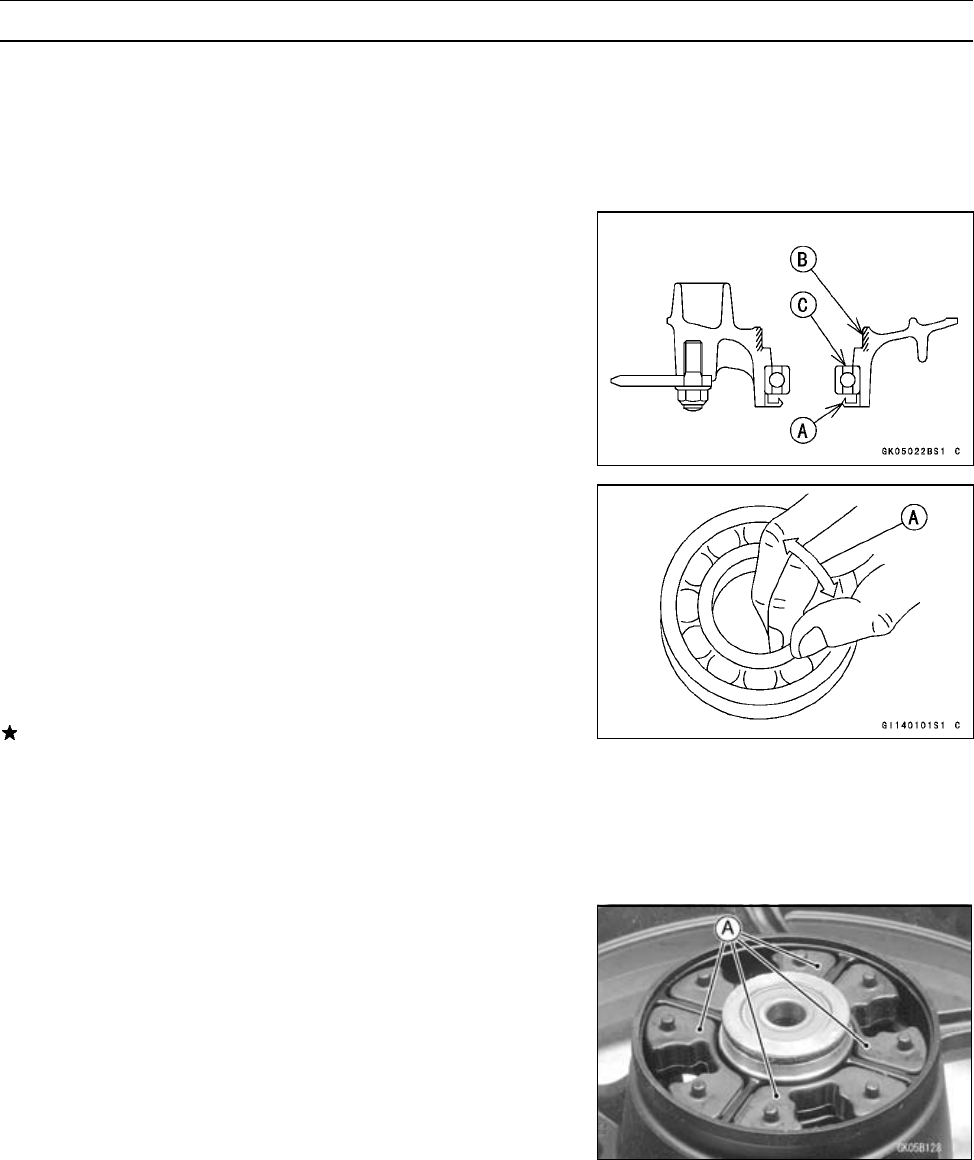

Coupli ng Installation

•

Grease the following and install the coupling.

Coupling Grease Seal [A]

Coupling Internal Surface [B]

Ball Bearing [C]

Coupling Bearing Inspection

Since the coupling bearing is made to extremely close

tolerances, the clearance can not normally be m easured.

NOTE

○

It is not necessary to remove the coupling bearing for

inspection. If the bearing is removed, it will need to be

replaced with a new one.

•

Spin [A] it by hand to check its condition.

If it is noisy, does not spin smoothly, or has any rough

spots, it m ust be replaced.

Coupling Bearing Lubrication

•

Pack the bearing with good quality bearing grease. Turn

the bearing around by hand a few times to make sure the

grease is distributed uniformly inside the bearing.

Coupling Damper Inspection

•

Remove the rear wheel coupling, and inspect the rubber

dampers [A].

•

Replace the damper if it appears damaged or deterio-

rated.