PERIODIC MAINTENANCE 2-29

Periodic M aintenance Procedures

Drive Chain Lubrication

•

If a special lubricant is not available, a heavy oil such as

SAE 90 is preferred to a lighter oil because it will stay on

the chain longer and provide better lubrication.

•

If the chain appears especially dirty, clean it before lubri-

cation.

CAUTION

The O -rings between the side plates seal in the lu-

bricant between the pin and the bushing. To avoid

damaging the O-rings and resultant loss of lubri-

cant, observe the following rules.

Use only kerosene or diesel oil for cleaning an O

-ring drive chain. Any other cleaning solution such

as gasoline or trichloroethylene will cause deterio-

ration and swelling of the O-ring. Immediately blow

the chain dry with compressed air after cleaning.

Complete cleaning and drying the chain within 10

minutes.

•

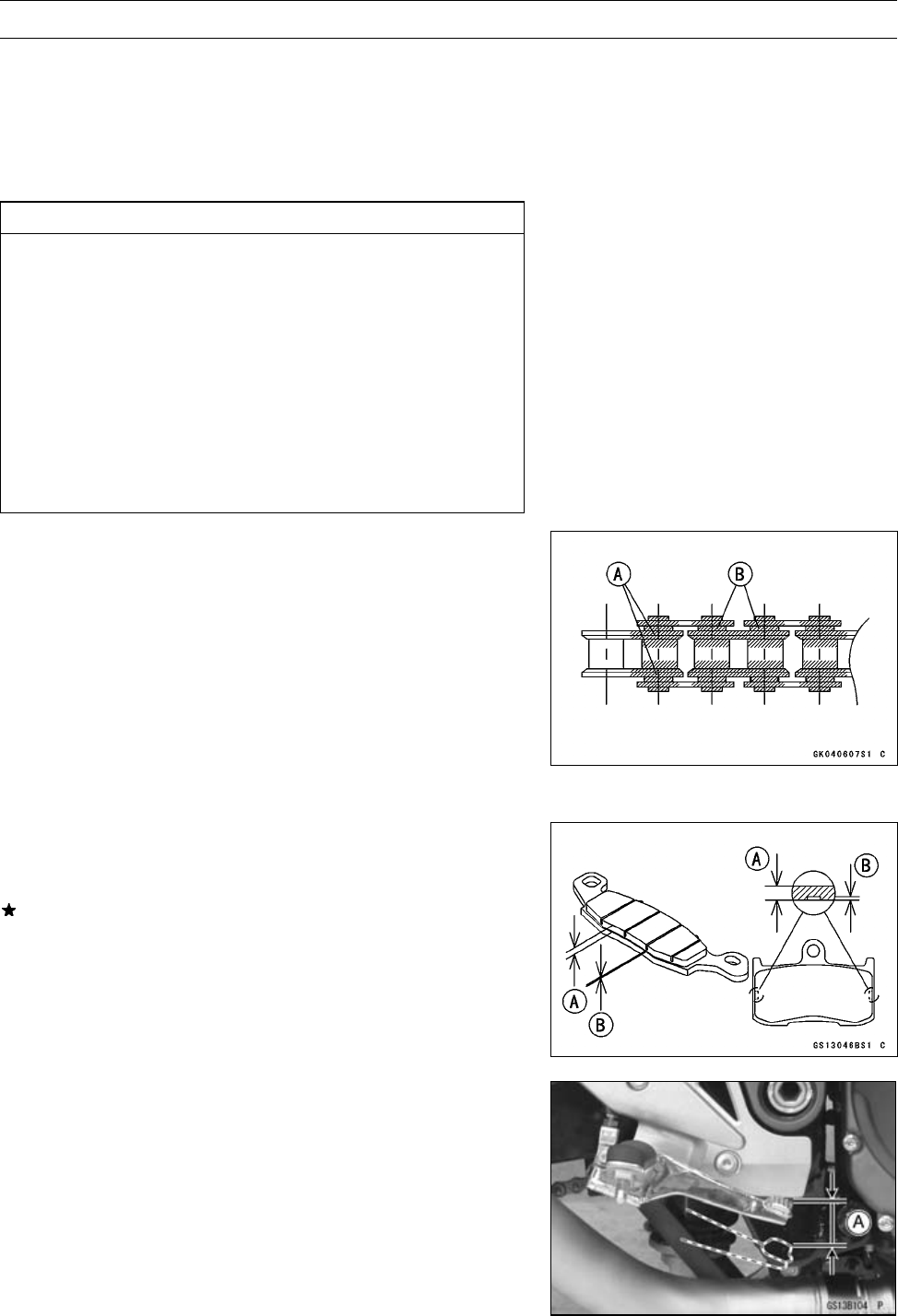

Apply oil to the sides of the rollers so that oil will penetrate

to the r ollers and bushings. Apply the oil to the O-rings so

that the O-rings will be coated with oil.

•

Wipe off any excess oil.

Oil Applied Areas [A]

O-rings [B]

Brakes

Brake Pad Wear Inspection

•

Remove the brake pads (see Brakes chapter).

•

Check the lining thickness [A] of the pads in each caliper.

If the lining thickness of either pad is less than the service

limit [B], replace both pads in the caliper as a set.

Pad Lining Thickness

Standard: Front 4.5 mm (0.18 in.)

Rear 5 mm (0.20 in.)

Service Limit: 1 mm (0.04 in.)

Rear Brake Light Switch Inspection/Adjustment

•

Turn on the ignition switch.

•

Check the operation of the rear brake light switch by de-

pressing the brake pedal. The brake light should go on

after about 10 mm (0.39 in.) of the pedal travel [A].