9-14 CRANKSHAFT/T RANSMISSION

Crankshaft and Connecting Rods

•

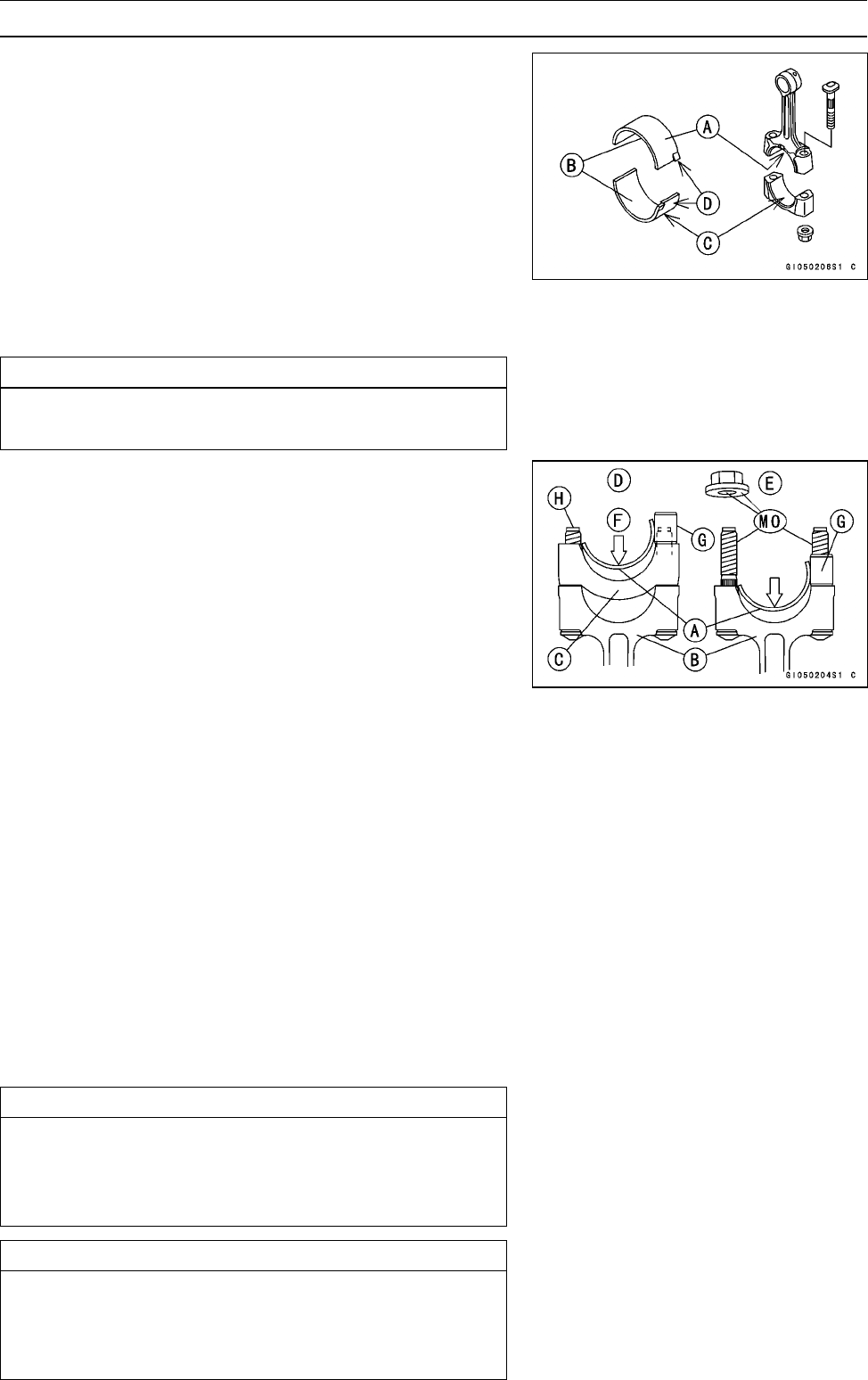

Apply molybdenum disulfide grease [A] to the outer sur-

face of the upper insert and the inner surface of the con-

necting rod big end.

•

Apply molybdenum disulfide oil [B] to the inner surfaces

of upper and lower bearing inserts.

○

The molybdenum disulfide oil is a m ixture of engine oil

and molybdenum disulfide grease with a weight ratio

(10:1).

○

Do not apply any grease or oil [C] to the cap inside and

cap insert outside.

○

Install the inserts so that their nails [D] are on the same

side and fit them into the recess of the connecting rod and

cap.

CAUTION

Wrong application of oil and grease could cause

bearing damage.

○

When installing the inserts [A], be careful not to damage

the insert surface with the edge of the connecting rod [B]

or the cap [C]. One way to install inserts is as follows:

Installation [D] to Cap

Installation [E] to Connecting Rod

Push [F]

Spare Dowel Pin [G]

Connecting Rod Bolts [H]

•

Install the cap on the connecting rod, aligning the weight

and diameter marks.

•

Remove debris and clean the surface of inserts.

•

Apply molybdenum disulfide oil [MO] to the threads and

seating surfaces of the big end nuts and bolts.

•

Install the crankshaft (see Crankshaft Installation).

•

Install each connecting rod on its original crankpin.

○

The connecting rod big end is bolted using the “plastic

region fastening method”.

○

This method precisely achieves the needed clamping

force without exceeding i t unnecessarily, allowing the

use of thinner, lighter bolts further decreasing connecting

rod weight.

○

There are two types of the plastic region fastening. One is

a bolt length measurement method and other is a rotation

angle method. Observe one of the following two, but the

bolt length measurement method is preferable because

this is a more reliable way to tighten the big end nuts.

CAUTION

The connecting rod bolts are designed to stretch

when tightened. Never reuse the connecting rod

bolts. See the table below for correct bolt and nut

usage.

CAUTION

Be careful not to overtighten the nuts.

The bolts must be positioned on the seating surface

correctly to prevent the bolt heads from hitting the

crankcase.