2-22 PERIODIC MAINTENANCE

Periodic Maintenance Procedures

Engine Top End

Air Suction Valve Inspection

•

Remove the air suction valve (see Engine Top End chap-

ter).

•

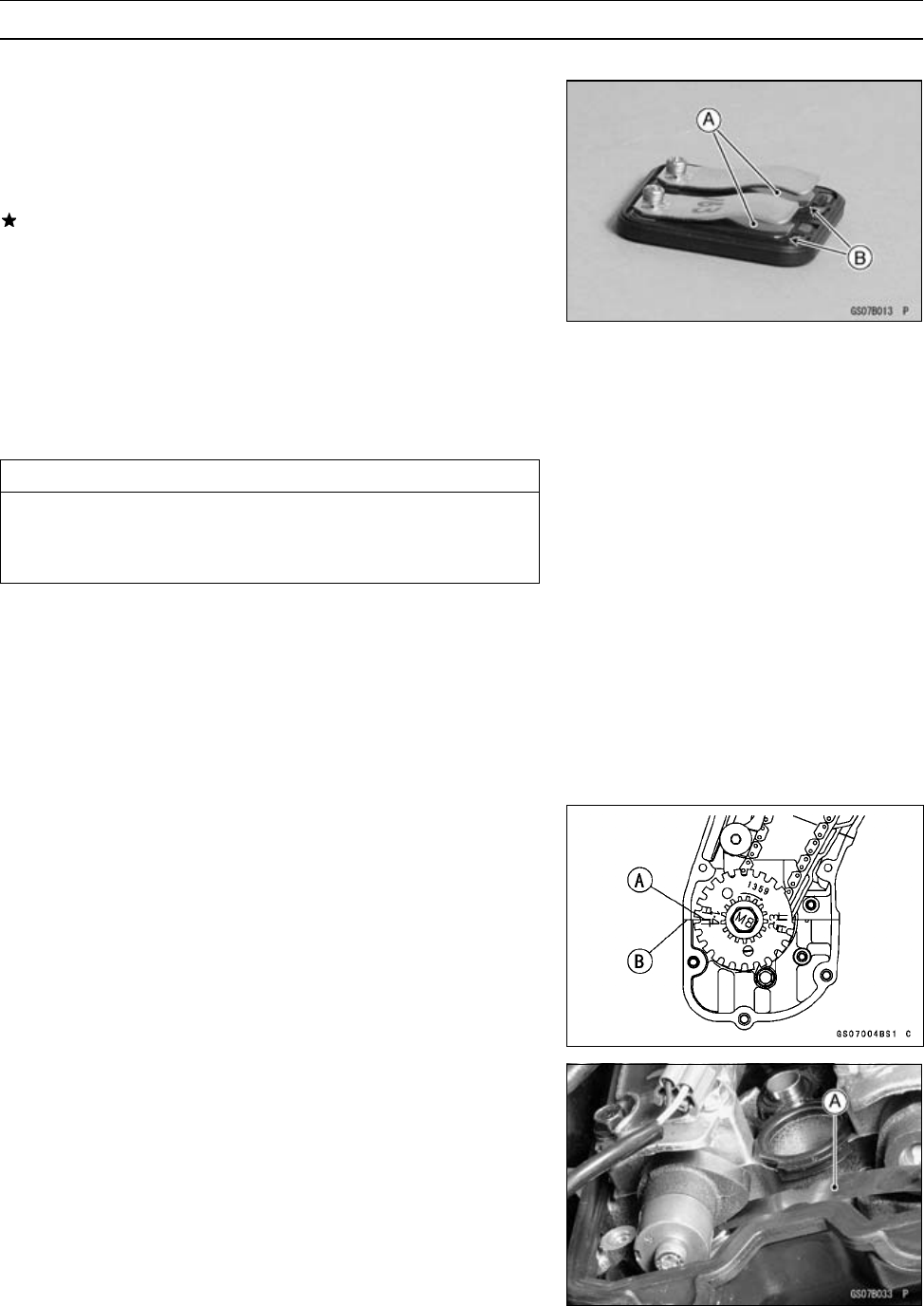

Visually inspect the reeds for cracks, folds, warps, heat

damage or other damage.

If there is any doubt as to the condition of the reeds [A],

replace the air suction valve as an assembly.

•

Check the reed contact areas [B] of the valve holder for

grooves, scratches, any signs of separation from the

holder or heat damage.

•

If there is any doubt as to the condition of the reed contact

areas, replace the air suction valve as an assembly.

•

If any carbon or other foreign particles have accumulated

between the reed and the reed contact area, wash the

valve assembly clean with a high-flash point solvent.

CAUTION

Do not scrape off the deposits with a scraper as this

could dam age the rubber, requiring replacement of

the suction valve assembly.

Valve Clearance Inspection

NOTE

○

Valve clearance must be checked and adjusted when

the engine is cold (at room temperature).

•

Remove:

Pickup Coil C over

Cylinder Head Cover (see Engine Top End chapter)

•

Position the crankshaft at 1,4 piston TDC.

TDC Mark [A] for #1, 4 Pistons

Timing Mark (crankcase halves mating surface) [B]

•

Using the thickness gauge [A], m easure the valve clear-

ance between the cam and the valve lifter.

Valve Clearance

Standard:

Inlet:

0.15 ∼ 0.24 mm (0.0059 ∼ 0.0094 in.)

Exhaust:

0.22 ∼ 0.31 mm (0.0087 ∼ 0.0122 in.)