9-16 CRANKSHAFT/T RANSMISSION

Crankshaft and Connecting Rods

(2) Rotation Angle Method

If you don’t have a point micrometer, you may tighten the

nuts using the “Rotation Angle Method”.

•

Be sure to clean the bolts and nuts thoroughly with a high

-flash point solvent, because the new bolts and nuts are

treated with an anti-rust solution.

WARNING

Clean the bolts and nuts in a well-ventilated area,

and take care that there is no spark or flame any-

where near the working area. This includes any ap-

pliance with a pilot light. Because of the danger

or highly flammable liquids, do not use gasoline or

low-flash point solvents to clean them.

CAUTION

Immediately dry the bolts and nuts with com-

pressed air after cleaning.

Clean and dry the bolts and nuts com pletely.

•

Install new bolts in reused connecting rods.

•

Apply a small am ount of molybdenum disulfide oil to the

following:

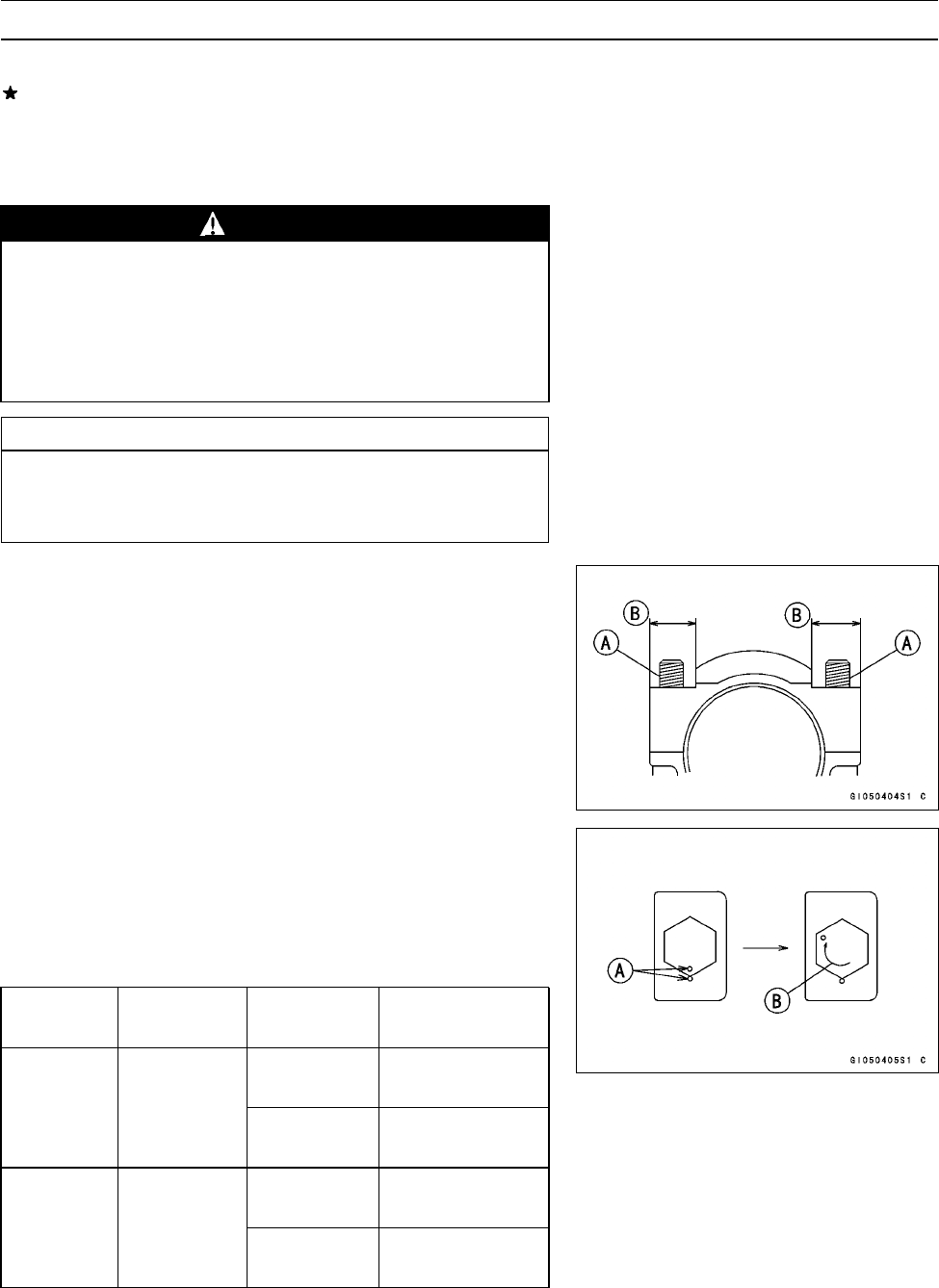

Threads [A] of Nuts and Bolts

Seating Surfaces [B] of Nuts and Con-rods

•

First, tighten the nuts to the specified torque. See the

table below.

•

Next, tighten the nuts 120° ±5° .

○

Mark [A] the connecting rod big end caps and nuts so that

nuts can be turned 120° [B] properly.

○

Tighten the hexagon nut by 2 corners.

Torque + Angle

Connecting

Rod Assy

Bolt Nu t

N·m (kgf·m, ft·lb)

Attached to 18 (1.8, 13.0)

new con-rod +120°

20 (2.0, 14.5)

New

Use the bolts

attached to

new con-rod.

New

+120°

24 (2.4, 17.4)

Used

+120°

25 (2.6, 18.8)

Used

Replace the

bolts with new

ones

New

+120°

Crankshaft/Connecting Rod Cleaning

•

After removing the connecting rods from the crankshaft,

clean them with a high-flash point solvent.

•

Blow the crankshaft oil passages with compressed air to

remove any foreign particles or residue that may have

accumulated in the passages.