6-12 CLUTCH

Clutch

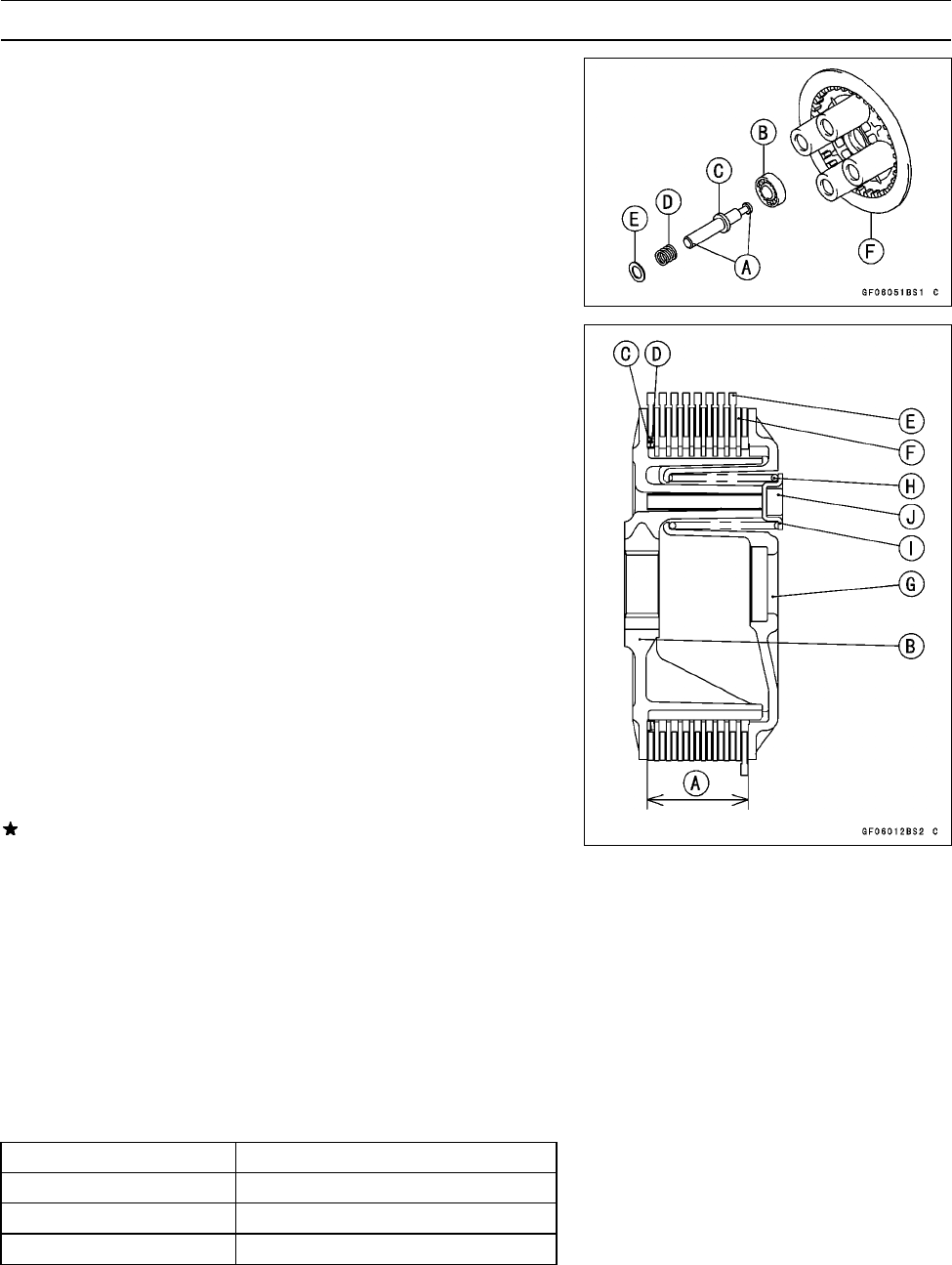

•

Apply molybdenum disulfide grease to the pusher ends

[A] and install the bearing [B], pusher [C], spring [D] and

washer [E] in the clutch spring plate [F].

○

Apply engine oil to the needle bearing.

•

Install the clutch spring plate, springs and spring holders,

and tighten the clutch spring bolts.

Torque - Clutch Spring Bolts: 8.8 N·m (0.90 kgf·m, 78 in·lb)

•

Install the clutch cover (see Clutch Cover Installation).

Clutch Plate Assembly Inspection

•

Inspect the friction plate thickness (see Clutch Plate,

Wear, Damage Inspection).

•

Measure the length [A] of the clutch plate assembly as

shown.

○

Assemble:

Clutch Hub [B]

Spring Seat [C]

Spring [D]

Friction Plates [E]

Steel Plates [F]

Spring Plate [G]

Springs [H]

Spring Holders [I]

Spring Bolts [J]

Torque - Clutch Spring Bolts: 8.8 N·m (0.90 kgf·m, 78 in·lb)

Clutch Plate Assembly

Standard: 37.7 ∼ 38.3 mm (1.48 ∼ 1.51 in.)

If the length is not within the specified r ange, adjust the

length (see Clutch Plate Assembly Adjustment).

Clutch Plate A ssem bly Adjustment

•

Inspect the clutch plate assembly length, and then re-

place the steel plate(s) which brings the length within the

specified range.

•

Remove:

Spring Bolts

Spring Holders

Springs

Spring Plate

•

Replace the following steel plate(s).

Part No. Thickness

13089–1126 1.4 mm (0.055 in.)

13089–013 1.6 mm (0.063 in.) (STD)

13089–1073 2.0 mm (0.079 in.)

NOTE

○

Do not use the steel plate of 1.4 mm (0.055 in.) and 2.0

mm (0.079 in.) thickness at the same time.

•

Install the removed parts, and inspect the clutch plate as-

sembly length.

Torque - Clutch Spring Bolts: 8.8 N·m (0.90 kgf·m, 78 in·lb)