CRANKSHAFT/TRANSMISSION 9-13

Crankshaft and Connecting Rods

Crankshaft Removal

•

Split the crankcase (see Crankcase S plitting).

•

Remove the crankshaft [A].

Crankshaft Installation

CAUTION

If the crankshaft, bearing inserts, or crankcase

halves are replaced with new ones, select the bear-

ing inserts and check clearance with a plastigage

(press gauge) before assembling engine to be sure

the correct bearing inserts are installed.

•

Apply molybdenum disulfide oil solution to the crankshaft

main bearing inserts.

•

Install the crankshaft with the camshaft chain [A] hanging

on it.

Connecting Rod Removal

•

Split the crankcase (see Crankcase S plitting).

•

Remove the connecting rod nuts [A].

•

Remove the crankshaft.

NOTE

○

Mark and record the locations of the connecting rods

and their big end caps so that they can be reassembled

in their original positions.

•

Remove the connecting rods from the crankshaft.

CAUTION

Discard the connecting rod bolts. To prevent dam-

age to the crankpin surfaces, do not allow the con-

necting rod bolts to bump against the crankpins.

Connecting Rod Install ation

CAUTION

To minimize vibration, the connecting rods should

have the sam e weight mark.

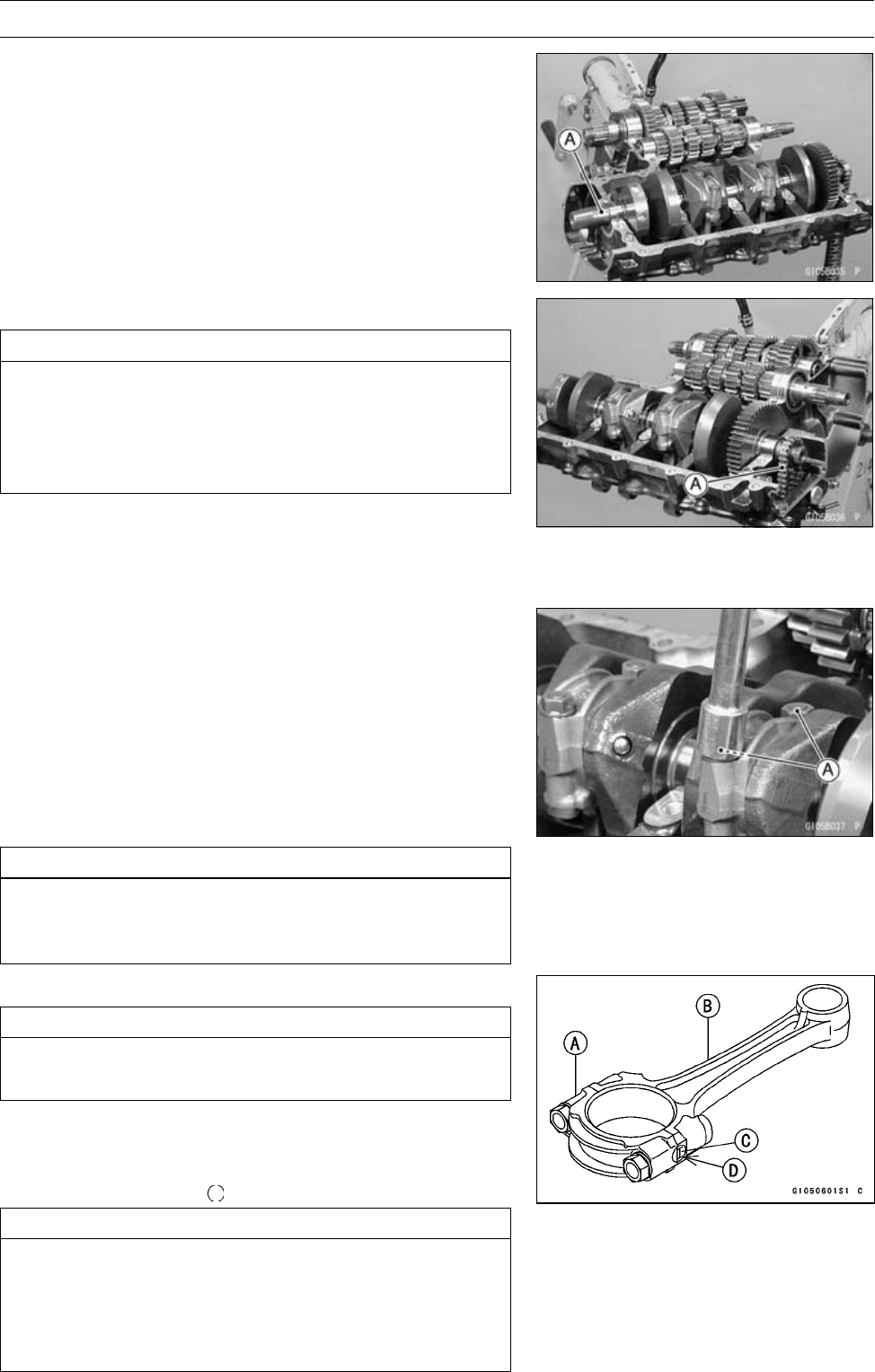

BigEndCap[A]

Connecting Rod [B]

Weight Mark, Alphabet [C]

Diameter Mark [D]: “

”ornomark

CAUTION

If the connecting rods, big end bearing inserts, or

crankshaft are replaced with new ones, select the

bearing insert and check clearance with a plasti-

gage (press gauge) before assembling engine to be

sure the correct bearing inserts are installed.