16-32 ELECTRICAL SYSTEM

Charging System

•

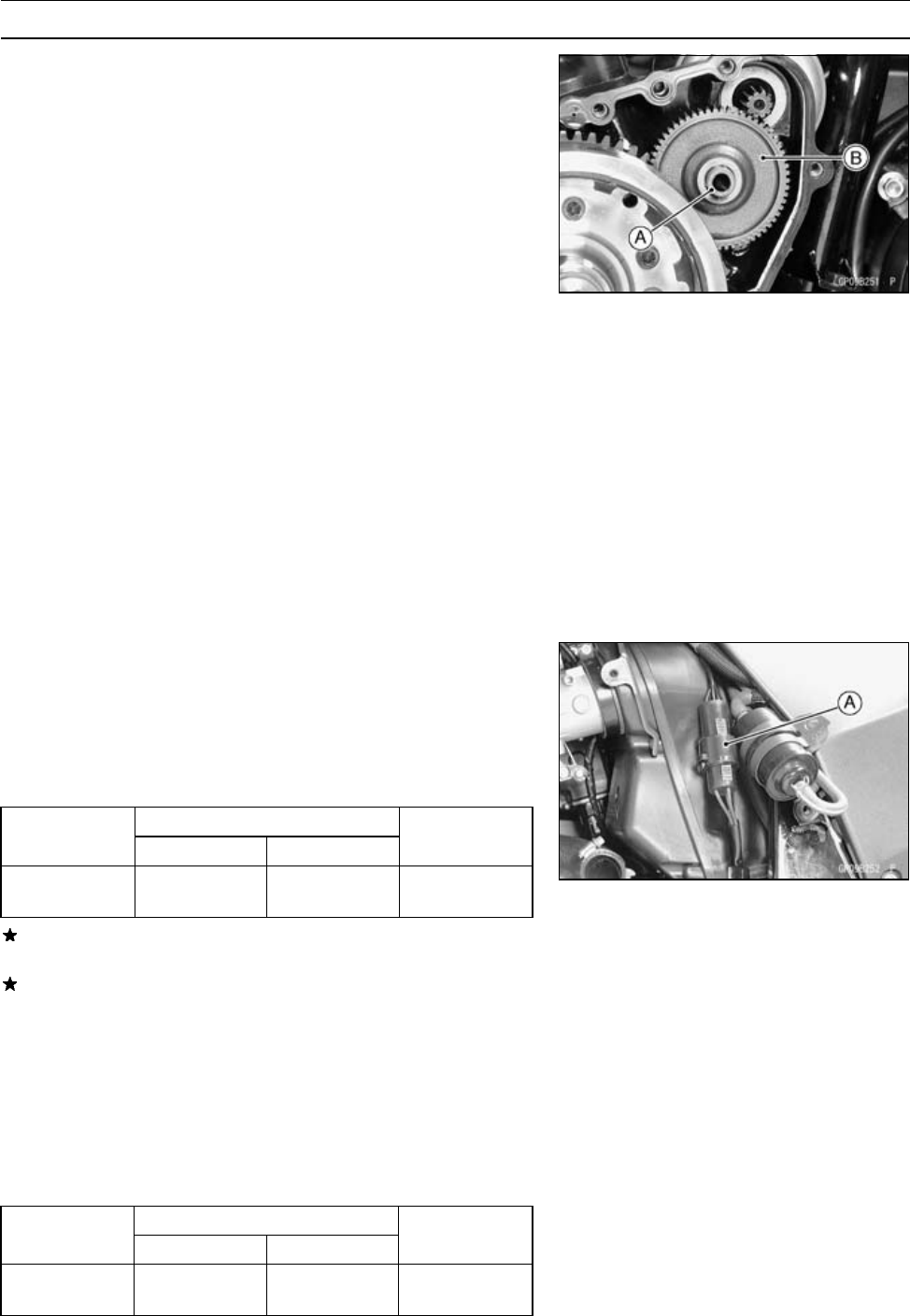

Apply a thin coat of molybdenum disulfide grease to the

shaft [A], and install it and starter idle gear [B].

•

Install the alternator cover (see Alternator Cover Installa-

tion).

Alternator Inspection

There are three types of alternator failures: short, open

(wire burned out), or loss in rotor magnetism. A short or

open in one of the coil wires will result in either a low output,

or no output at all. A loss in rotor magnetism, which may be

caused by dropping or hitting the alternator, by leaving it

near an electromagnetic field, or just by aging, will result in

low output.

•

To check the alternator output voltage, do the following

procedures.

○

Turn off the ignition switch.

○

Remove the left frame cover (see Alternator Cover Re-

moval).

○

Disconnect the alternator lead connector [A].

○

Connect the hand tester as shown in the table 1.

○

Start the engine.

○

Run it at the rpm given in the table 1.

○

Note the voltage readings (total 3 measurements).

Table 1 Alternator Output Voltage

Tester Connections Reading

Range Tester (+) to Te ster ( –) to @ 4,000 rpm

250 V AC

One Black

lead

Another Black

lead

42 V or more

If the output voltage shows the value in the table, the al-

ternator operates properly.

If the output voltage shows a much higher than the v alue

in the table, the regulator/rectifier is dam aged. A much

lower reading than that given in the table indicates that

the alternator is defective.

•

Check the stator coil resistance as follows.

○

Stop the engine.

○

Connect the hand tester as shown in the table 2.

○

Note the readings (total 3 measurement).

Table 2 Stator Coil Resistance

Tester

Connections

Range

Tester (+) to Tester (–) to

Reading

×1Ω

One Black

lead

Another Black

lead

0.3 ∼ 0.4 Ω