CRANKSHAFT/TRANSMISSION 9-19

Crankshaft and Connecting Rods

•

Measure the connecting rod big end inside diameter, and

mark each connecting rod big end in accordance with the

inside diameter.

•

Tighten the connecting rod big end nuts to the specified

torque (see Connecting Rod Installation).

NOTE

○

The mark already on the big end should almost coincide

with the measurement.

Connecting Rod Big End Inside Diameter Marks

None

38.000 ∼ 38.008 mm (1.4961 ∼ 1.4964 in.)

38.009 ∼ 38.016 mm (1.4964 ∼ 1.4967 in.)

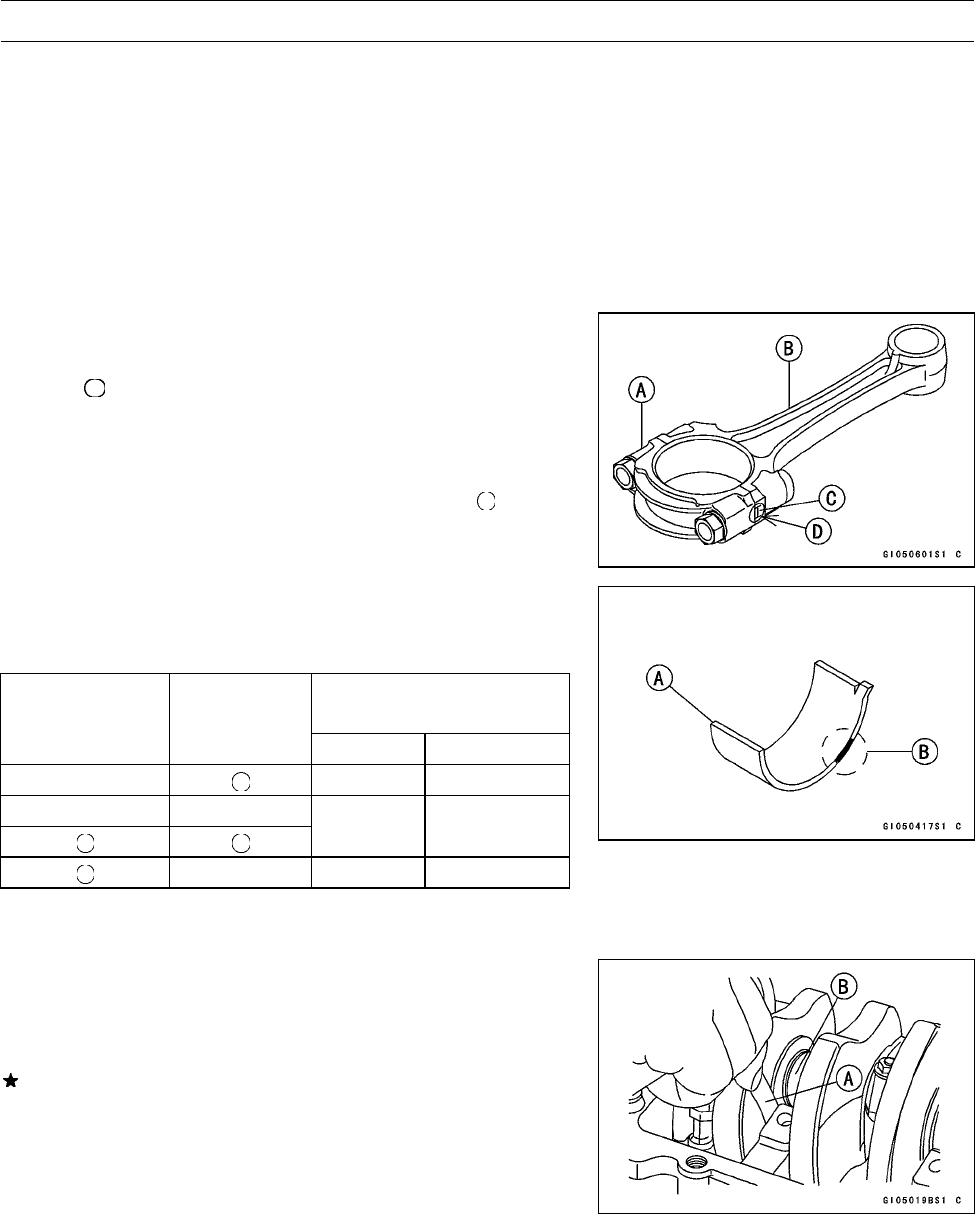

BigEndCap[A]

Connecting Rod [B]

Weight Mark, Alphabet [C]

Diameter Mark (Around Weight Mark) [D]: “

”orno

mark

•

Select the proper bearing insert [A] in accordance with the

combination of the connecting rod and crankshaft coding.

Size Color [B]

Bearing Insert

Con-rod Big End

Inside Diameter

Marking

Crankpin

Diameter

Marking

Size Color Part Number

None Brown 92139–1110

None None

Black 92139–1109

None Blue 92139–1108

•

Install the new inserts in the connecting rod and check

insert/crankpin clearance with the plastigage.

Crankshaft Side Clearance

•

Insert a thickness gauge [A] between the crankcase main

bearing and the crank web at the No. 2 journal [B] to

determine clearance.

If the clearance exceeds the service limit, replace t he

crankcase halves as a set.

NOTE

○

The upper and lower crankcase halves are machined

at the factory in the assembled state, so the crankcase

halves must be replaced as a set.

Crankshaft Side Clearance

Standard: 0.05 ∼ 0.20 mm (0.0020 ∼ 0.0079 in.)

Service Limit: 0.40 mm (0.0157 in.)