20

Reference Manual

00809-0100-4444, Rev AC

Section 2: Installation

January 2015

Quick Installation and Startup

2.10.2 Alignment

1. On 1.5 through 8-inch (40 through 200 mm) line sizes, Rosemount requires installing

the alignment spacers to ensure proper centering of the wafer sensor between the

process flanges.

2. Insert studs for the bottom side of the sensor between the pipe flanges and center the

alignment spacer in the middle of the stud. See Figure 2-9 for the bolt hole locations

recommended for the spacers provided. Stud specifications are listed in Table 2-7.

3. Place the sensor between the flanges. Make sure the alignment spacers are properly

centered on the studs. For vertical flow installations slide the O-ring over the stud to

keep the spacer in place. See Figure 2-9. Ensure the spacers match the flange size and

class rating for the process flanges. See Table 2-8.

4. Insert the remaining studs, washers, and nuts.

5. Tighten to the torque specifications shown in Table 2-9. Do not over-tighten the bolts

or the liner may be damaged.

Table 2-7. Stud Specifications

Nominal sensor size Stud specifications

1.5 through 8-in. (40 through 200 mm) CS, ASTM A193, Grade B7, threaded mounting studs

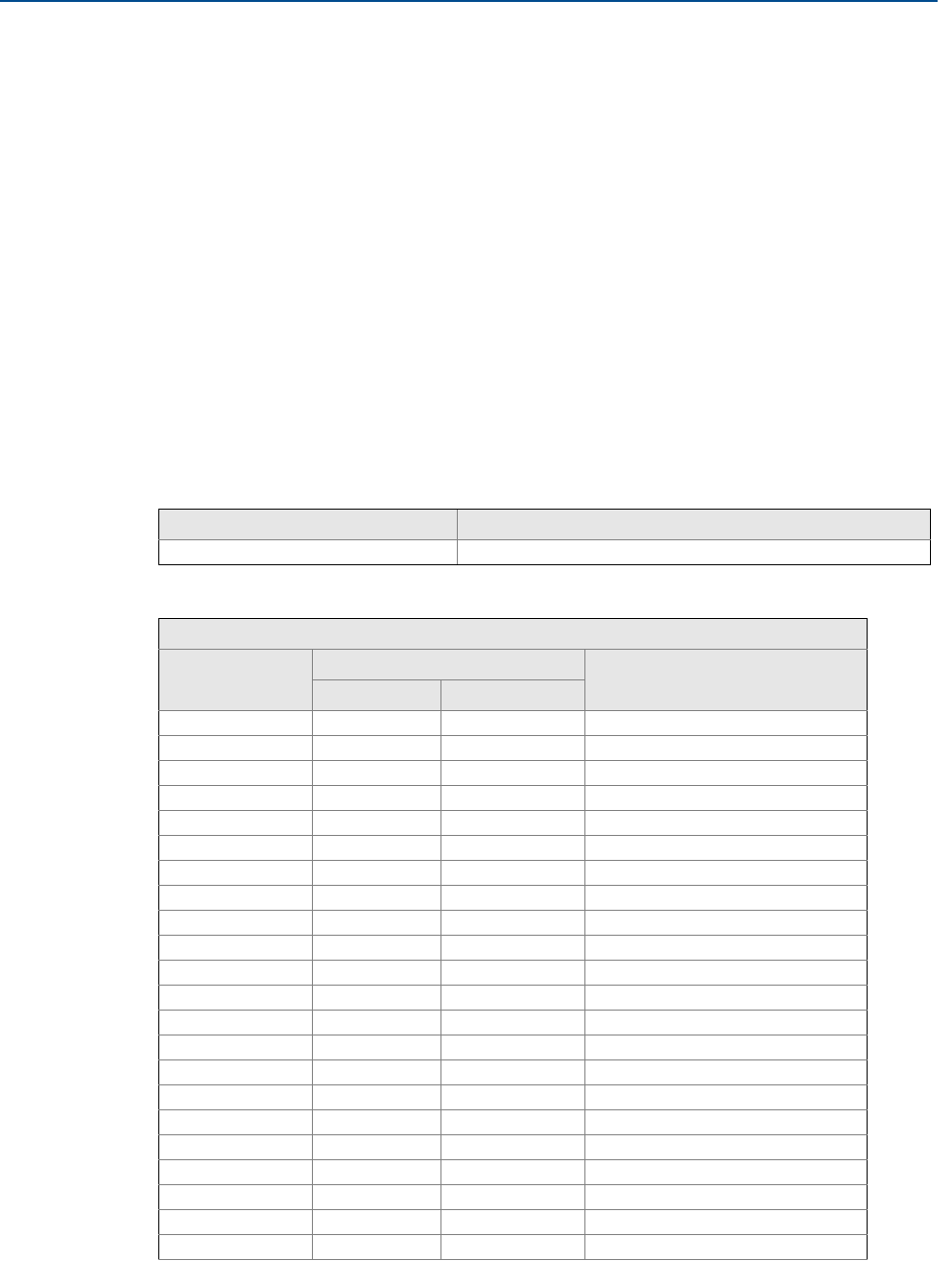

Table 2-8. Rosemount Alignment Spacer Table

Rosemount alignment spacer table

Dash no.

(-xxxx)

Line size

Flange rating(in) (mm)

0A15 1.5 40 JIS 10K-20K

0A20 2 50 JIS 10K-20K

0A30 3 80 JIS 10K

0B15 1.5 40 JIS 40K

AA15 1.5 40 ASME- 150#

AA20 2 50 ASME - 150#

AA30 3 80 ASME - 150#

AA40 4 100 ASME - 150#

AA60 6 150 ASME - 150#

AA80 8 200 ASME - 150#

AB15 1.5 40 ASME - 300#

AB20 2 50 ASME - 300#

AB30 3 80 ASME - 300#

AB40 4 100 ASME - 300#

AB60 6 150 ASME - 300#

AB80 8 200 ASME - 300#

DB40 4 100 EN 1092-1 - PN10/16

DB60 6 150 EN 1092-1 - PN10/16

DB80 8 200 EN 1092-1 - PN10/16

DC80 8 200 EN 1092-1 - PN25

DD15 1.5 40 EN 1092-1 - PN10/16/25/40

DD20 2 50 EN 1092-1 - PN10/16/25/40