15

Reference Manual

00809-0100-4444, Rev AC

Section 2: Quick Installation and Start-Up

January 2015

Quick Installation and Start-Up

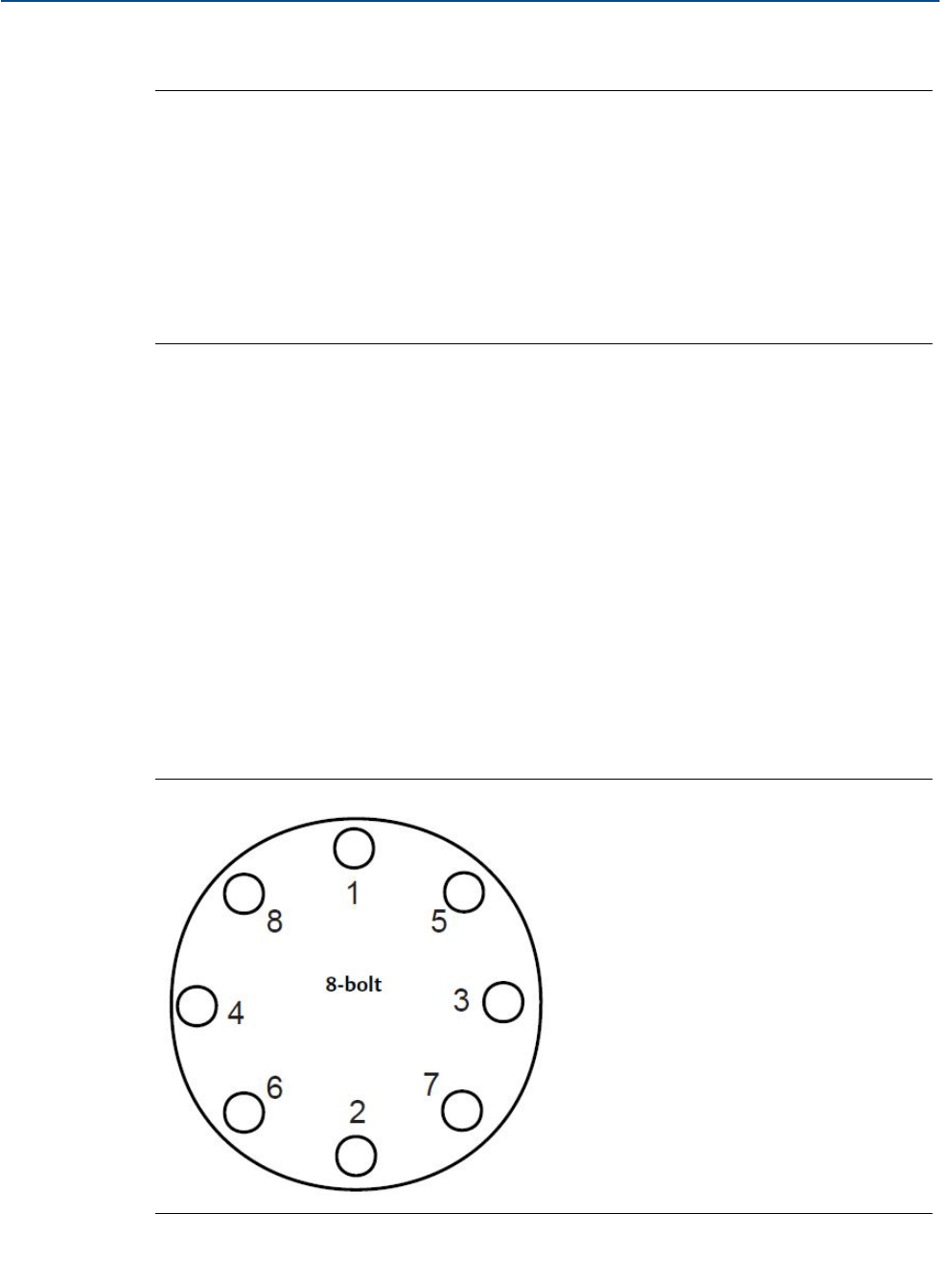

2.9.2 Flange bolts

Note

Do not bolt one side at a time. Tighten both sides simultaneously. Example:

1. Snug upstream

2. Snug downstream

3. Tighten upstream

4. Tighten downstream

Do not snug and tighten the upstream side and then snug and tighten the downstream side.

Failure to alternate between the upstream and downstream flanges when tightening bolts may

result in liner damage.

Suggested torque values by sensor line size and liner type are listed in Ta ble 2- 4 for ASME B16.5

flanges and Ta ble 2 -5 for EN flanges. Consult the factory if the flange rating of the sensor is not

listed. Tighten flange bolts on the upstream side of the sensor in the incremental sequence

shown in

Figure 2-8 to 20% of the suggested torque values. Repeat the process on the

downstream side of the sensor. For sensors with greater or fewer flange bolts, tighten the bolts

in a similar crosswise sequence. Repeat this entire tightening sequence at 40%, 60%, 80%, and

100% of the suggested torque values.

If leakage occurs at the suggested torque values, the bolts can be tightened in additional 10%

increments until the joint stops leaking, or until the measured torque value reaches the

maximum torque value of the bolts. Practical consideration for the integrity of the liner often

leads the user to distinct torque values to stop leakage due to the unique combinations of

flanges, bolts, gaskets, and sensor liner material.

Check for leaks at the flanges after tightening the bolts. Failure to use the correct tightening

methods can result in severe damage. While under pressure, sensor materials may deform over

time and require a second tightening 24 hours after the initial installation.

Figure 2-8. Flange Bolt Torquing Sequence