155

Reference Manual

00809-0100-4444, Rev AC

Section 9: Troubleshooting

January 2015

Tro ubles hooting

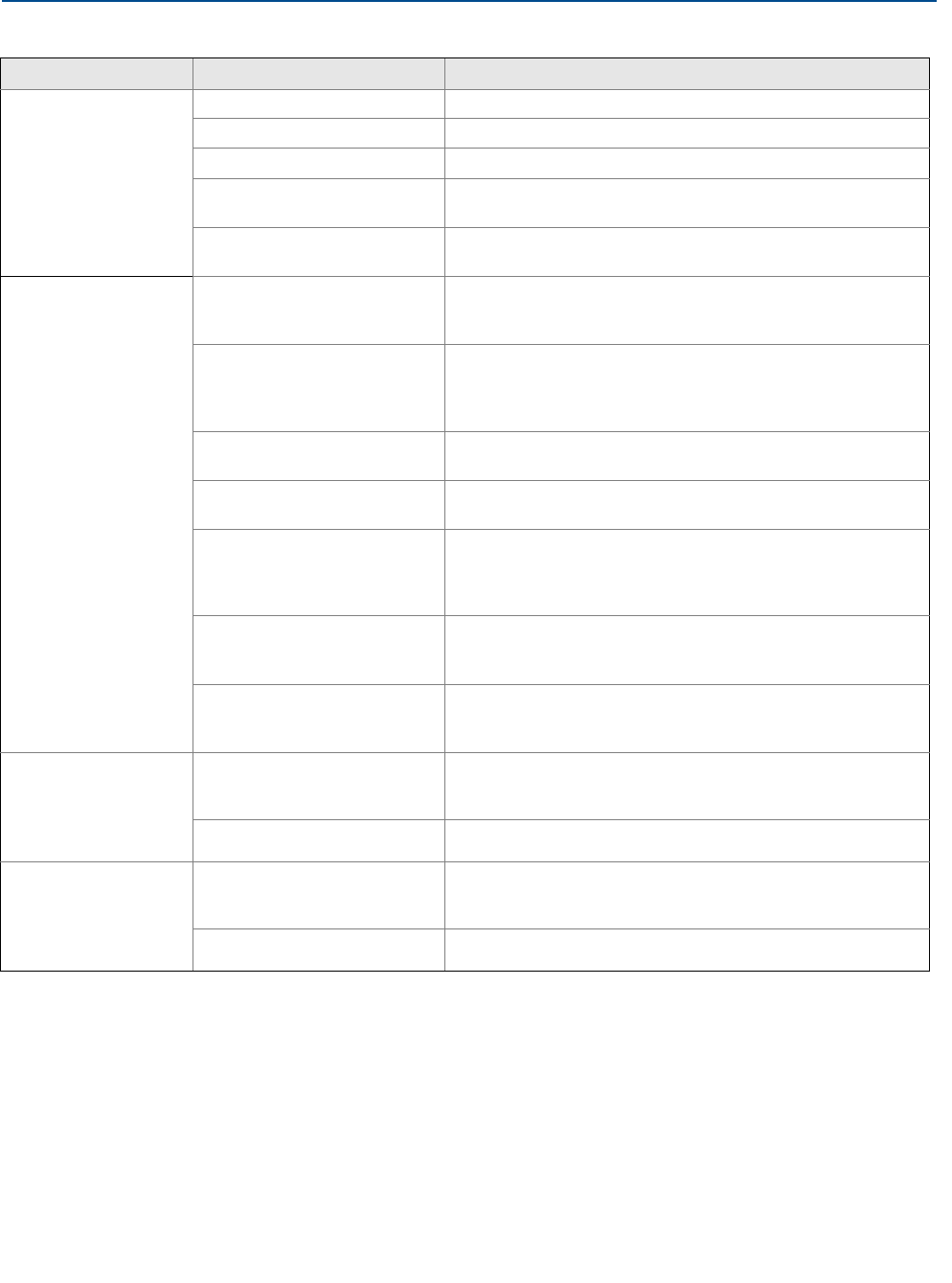

Table 9-2. Advanced Process Diagnostic Messages

Error message Potential cause Corrective action

Improper installation of wiring • See Wiring the transmitter on page 25

Grounding/Wiring Fault

Coil/electrode shield not connected •See Wiring the transmitter on page 25

Improper process grounding • See Process reference connection on page 21

Faulty ground connection

• Check wiring for corrosion, moisture in the terminal block -see

Process reference connection on page 21

Sensor not full

• Verify sensor is full

• Enable empty pipe detection

High Process Noise

Slurry flows - mining/pulp stock

• Decrease the flow rate below 10 ft/s (3 m/s)

• Complete the possible solutions listed under Troubleshooting high

process noise on page 158

Chemical additives upstream of the

sensor

• Move injection point downstream of the sensor or move the sensor to

a new location

• Complete the possible solutions listed under Troubleshooting high

process noise on page 158

Electrode not compatible with the

process fluid

•Refer to the Rosemount Magnetic Flowmeter Material Selection Guide

(00816-0100-3033)

Gas/air in line

• Move the sensor to another location in the process line to ensure that

it is full under all conditions

Electrode coating

• Enable coated electrode etection diagnostic

• Use bullet-nose electrodes

• Downsize sensor to increase flowrate above 3 ft/s (1 m/s)

•Periodically clean sensor

Styrofoam or other insulating

particles

• Complete the possible solutions listed under Troubleshooting high

process noise on page 158

• Consult factory

Low conductivity fluids

(below 10 microsiemens/cm)

• Trim electrode and coil wires - see Sensor installation on page 14

• Use integral mount transmitter

• Set coil drive frequency to 37Hz

Electrode Coating Level 1

Coating is starting to buildup on

electrode and interfering with

measurement signal

• Schedule maintenance to clean electrode

• Use bullet nose electrodes

• Downsize sensor to increase flow rate above 3ft/s (1ms)

Process fluid conductivity has

changed

• Verify process fluid conductivity

Electrode Coating Level 2

Coating has built-up on electrode

and is interfering with measurement

signal

• Schedule maintenance to clean electrode

• Use bullet nose electrodes

• Downsize sensor to increase flow rate above 3ft/s (1ms)

Process fluid conductivity has

changed

• Verify process fluid conductivity