169

Reference Manual

00809-0100-4444, Rev AC

Section 9: Troubleshooting

January 2015

Tro ubles hooting

9.6.3 Installed sensor tests

If a problem with an installed sensor is identified, refer to Table 9-8 on page 168 to assist in trou-

bleshooting the sensor. Disconnect or turn off power to the transmitter before performing any

of the sensor tests. Always check the operation of test equipment before each test.

If possible, take all readings from feed-through pins in the sensor adapter. If the pins in the

sensor adapter are inaccessible, take measurements at the sensor terminal block or through

remote cabling as close to the sensor as possible. Readings taken through remote cabling that is

more than 100 feet (30 meters) in length may provide incorrect or inconclusive information and

should be avoided.

The expected values in the test below assume the measurements have been taken directly at

the pins.

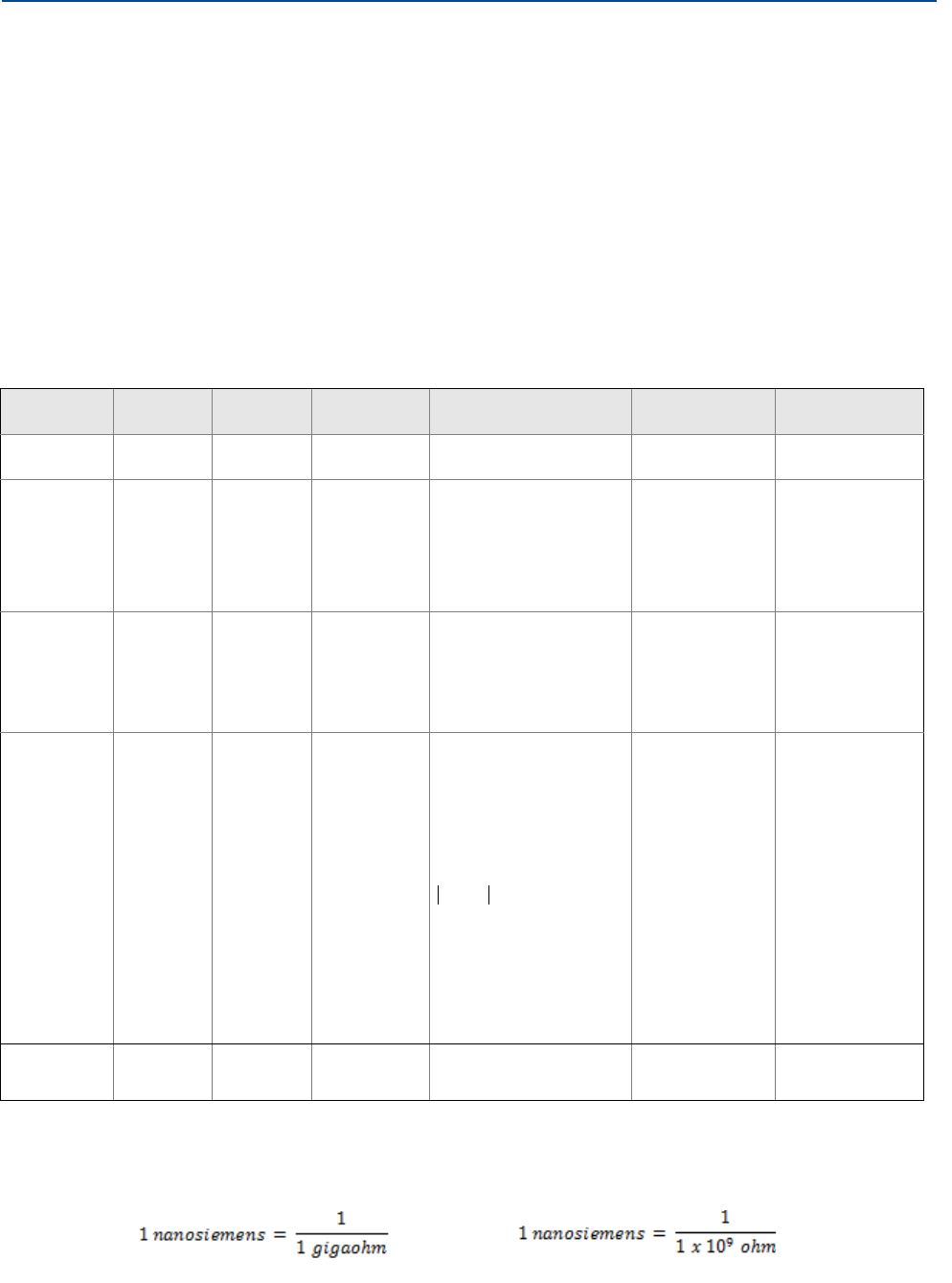

To test the sensor, a multimeter capable of measuring conductance in nanoSiemens is

preferred. Conductance is the reciprocal of resistance.

Or:

Table 9-8. Sensor Tests and Expected Values

Test

Sensor

location

Required

equipment

Measuring at

connections Expected value Potential cause Corrective action

A. Sensor coil

Installed or

uninstalled

Multimeter 1 and 2 = R

• Open or shorted

coil

•Remove and

replace sensor

B. Shields to

case

Installed or

uninstalled

Multimeter

17 and 3

3 and case

ground

17 and case

ground

•Moisture in

terminal block

• Leaky electrode

• Process behind

liner

• Clean terminal

block

•Remove sensor

C. Coil to coil

shield

Installed or

uninstalled

Multimeter

1 and 3

2 and 3

(< 1nS)

(< 1nS)

• Process behind

liner

• Leaky electrode

•Moisture in

terminal block

•Remove sensor

and dry

• Clean terminal

block

• Confirm with

sensor coil test

D. Electrode to

electrode

shield

Installed

LCR (Set to

Resistance

and 120 Hz)

18 and 17 = R

1

19 and 17 = R

2

R

1

and R

2

should be stable

•Unstable R

1

or R

2

values confirm

coated electrode

•Shorted

electrode

•Electrode not in

contact with

process

• Empty pipe

• Low conductivity

• Leaky electrode

•Process

reference

ground not

connected

properly

•Remove coating

from sensor wall

•Use bullet-nose

electrodes

•Repeat

measurement

•Remove sensor

and complete

tests in Ta bl e 9- 9

• Connect process

reference ground

per 2.11 Process

reference

connection

E. Electrode to

Electrode

Installed

LCR (set to

resistance

and 120 Hz)

18 and 19

Should be stable and same

relative magnitude of R

1

and

R

2

from Test D

• See Test D above • See Test D above

2 R18

0.3

R

1

R–

2

300