160

Reference Manual

00809-0100-4444, Rev AC

Section 9: Troubleshooting

January 2015

Troubleshooting

a paper mill. The type of noise can be mitigated by switching to the 37Hz coil drive frequency

and enabling the digital signal processing.

White noise

This type of noise results in a high amplitude signal that is relatively constant over the frequency

range. Common sources of white noise include chemical reactions or mixing that occurs as the

fluid passes through the flowmeter and high concentration slurry flows where the particulates

are constantly passing over the electrode head. An example of this type of flow stream would be

a basis weight stream in a paper mill. This type of noise can be mitigated by switching to the

37Hz coil drive frequency and enabling the digital signal processing.

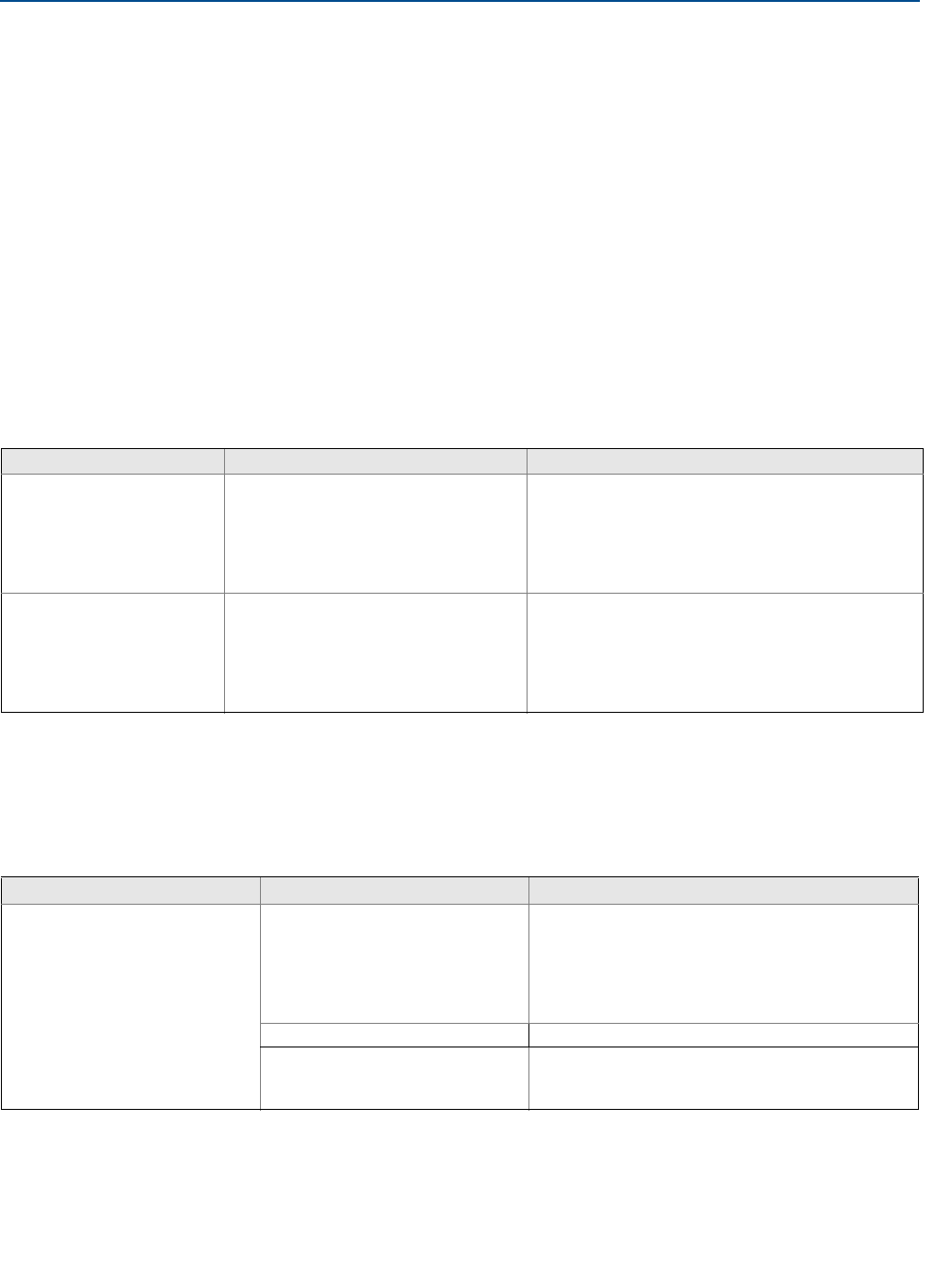

9.4.4 Troubleshooting coated electrode detection

In the event that electrode coating is detected, use the following table to determine the

appropriate course of action.

9.4.5 Troubleshooting 4-20 mA loop verification

In the event that the 4-20 mA Loop Verification fails, use the following table to determine the

appropriate course of action.

Table 9-4. Troubleshooting the Electrode Coating Diagnostic

Error message Potential causes of error Steps to correct

Electrode Coating Level 1

• Insulating coating is starting to build up on

the electrode and may interfere with the

flow measurement signal

• Process fluid conductivity has decreased to

a level close to operational limits of the

meter

• Verify process fluid conductivity

• Schedule maintenance to clean the electrodes

• Use bullet nose electrodes

• Replace the meter with a smaller diameter meter to

increase the flow velocity to above 3 ft/s (1 m/s)

Electrode Coating Level 2

• Insulating coating has built up on the

electrodes and is interfering with the flow

measurement signal

• Process fluid conductivity has decreased to

a level below the operational limits of the

meter

• Verify process fluid conductivity

• Schedule maintenance to clean the electrodes

• Use bullet nose electrodes

• Replace the meter with a smaller diameter meter to

increase the flow velocity to above 3 ft/s (1 m/s)

Table 9-5. Troubleshooting the Analog Loop Verification Diagnostic

Test Potential cause Corrective action

4-20 mA Loop Verification Failure

• Analog loop not powered • Check analog loop wiring

• Check loop resistance

• Check analog loop power switch – see Internal/external

analog power on page 42

• Check external supply voltage to the transmitter

• Check for parallel paths in the current loop

• Analog drift • Perform D/A trim

• Transmitter failure •Perform transmitter self-test

• Perform manual analog loop test

• Replace the electronics stack