164

Reference Manual

00809-0100-4444, Rev AC

Section 9: Troubleshooting

January 2015

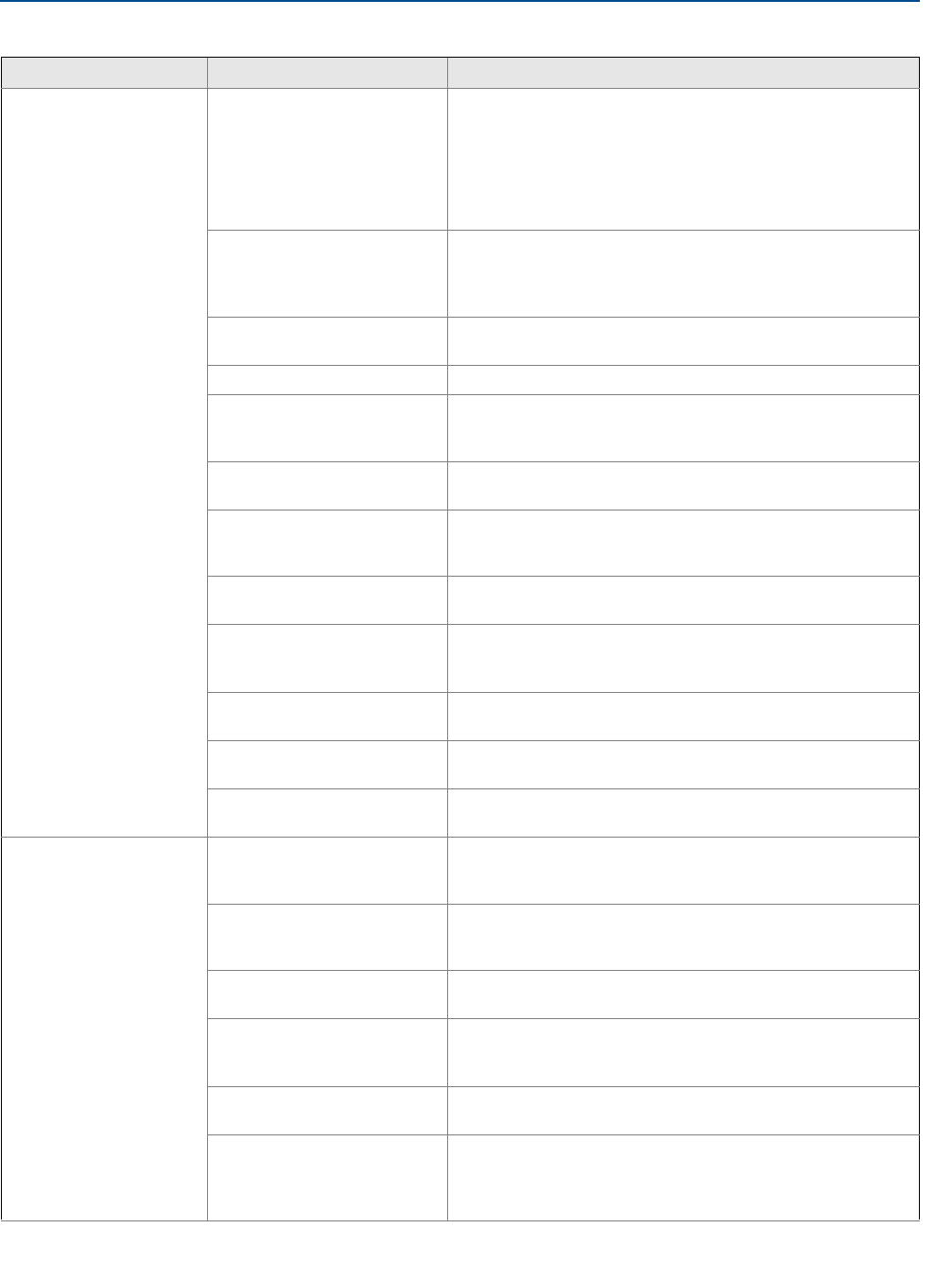

Troubleshooting

Reading does not appear to

be within rated accuracy

• Transmitter, control system, or

other receiving device not

configured properly

• Check all configuration variables for the transmitter, sensor,

communicator, and/or control system

• Check these other transmitter settings:

•Sensor calibration number

•Units

•Line size

•Perform a loop test to check the integrity of the circuit

• Electrode Coating •Enable Coated Electrode Detection diagnostic

• Use bullet-nose electrodes

• Downsize sensor to increase flow rate above 3 ft/s

• Periodically clean sensor

• Gas/air in line • Move the sensor to another location in the process line to ensure it is

full under all conditions

• Moisture problem •Perform the sensor tests - see Table 9-8 on page 168

• Insufficient

upstream/downstream pipe

diameter

• Move sensor to a new location with 5 pipe diameters upstream and 2

pipe diameters downstream if possible

• Cables for multiple magmeters

run through same conduit

• Use dedicated conduit run for each sensor and transmitter

• Improper wiring • If electrode shield and electrode signal wires are switched, flow

indication will be about half of what is expected. Check wiring

diagrams.

• Flow rate is below 1 ft/s

(specification issue)

• See accuracy specification for specific transmitter and sensor

• Auto zero was not performed

when the coil drive frequency

was changed from 5 Hz to 37 Hz

• Set the coil drive frequency to 37 Hz, verify the sensor is full, verify

there is no flow, and perform the auto zero function

• Sensor failure–shorted

electrode

• Perform the sensor tests - see Table 9-8 on page 168

• Sensor failure–shorted or open

coil

• Perform the sensor tests - see Table 9-8 on page 168

• Transmitter failure • Verify transmitter operation with an 8714 Calibration Standard or

replace the electronics board

Noisy Process

• Chemical additives upstream of

magnetic flowmeter

• See Troubleshooting high process noise on page 158

• Move injection point downstream of magnetic flowmeter, or move

magnetic flowmeter

• Sludge flows–mining/coal/

sand/slurries (other slurries with

hard particles)

• Decrease flow rate below 10 ft/s

• Styrofoam or other insulating

particles in process

• See Troubleshooting high process noise on page 158

• Consult factory

• Electrode coating • Enable Coated Electrode Detection diagnostic

• Use a smaller sensor to increase flow rate above 3 ft/s

• Periodically clean sensor

• Gas/air in line • Move the sensor to another location in the process line to ensure it is

full under all conditions

• Low conductivity fluids (below

10 microsiemens/cm)

• Trim electrode and coil wires – see Cable preparation on page 29

• Keep flow rate below 3 FPS

• Integral mount transmitter

• Use component cable - see Table 2-11 on page 27

Table 9-7. Common Magmeter Issue (continued)

Symptom Potential cause Corrective action