2-24 PERIODIC MAINTENANCE

Periodic Maintenance Procedures

Valve Clearance Inspection

NOTE

○

Valve clearance must be checked and adjusted when

the engine is cold (at room temperature).

•

Remove:

Lower Fairings (see Frame chapter)

Pickup Coil Cover

Cylinder Head Cover (see Cylinder Head Cover Re-

moval)

•

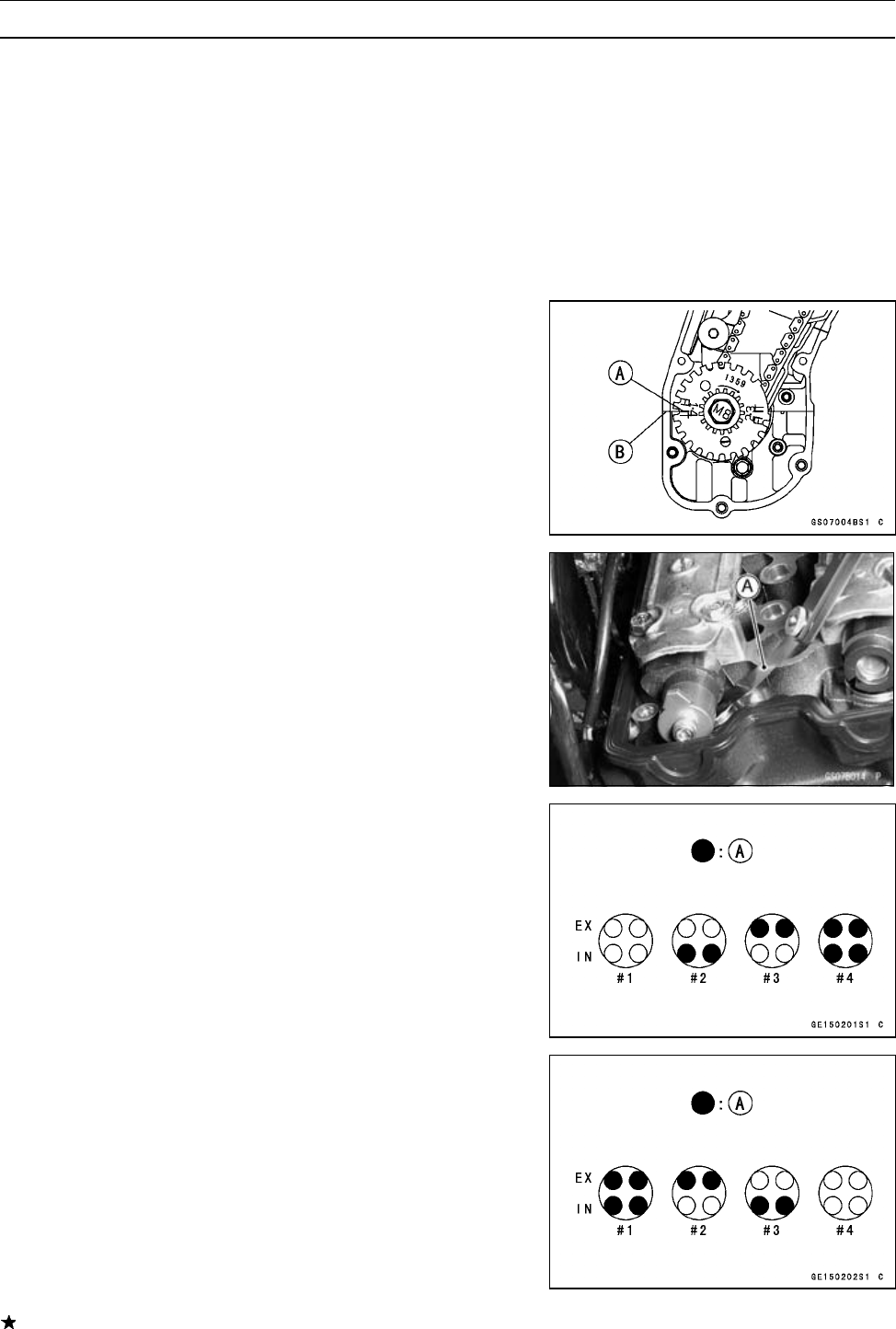

Position the crankshaft at 1,4 piston TDC.

TDC Mark [A] for #1, 4 Pistons

Timi

ng Mark [B]

•

Using a thickness gauge [A], measure the valve clearance

between the cam and the valve lifter.

Valve Clearance

Standard:

IN:

0.15 ∼ 0.24 mm (0.0059 ∼ 0.0094 in.)

EX: 0.22 ∼ 0.31 mm (0.0087 ∼ 0.0122 in.)

○

When positioning #4 piston TDC at the end of the

compression stroke:

Inlet valve clearance of #2 and #4 cylinders

Exhaust valve clearance of #3 and #4 cylinders

Measuring Valve [A]

○

When positioning #1 piston TDC at the end of the

compression stroke:

Inlet valve clearance of #1 and #3 cylinders

Exhaust valve clearance of #1 and #2 cylinders

Measuring Valve [A]

If the valve clearance is not within the specified range,

first record the clearance, and then adjust it.