PERIODIC MAINT EN ANCE 2-17

Periodic Maintenan ce Procedures

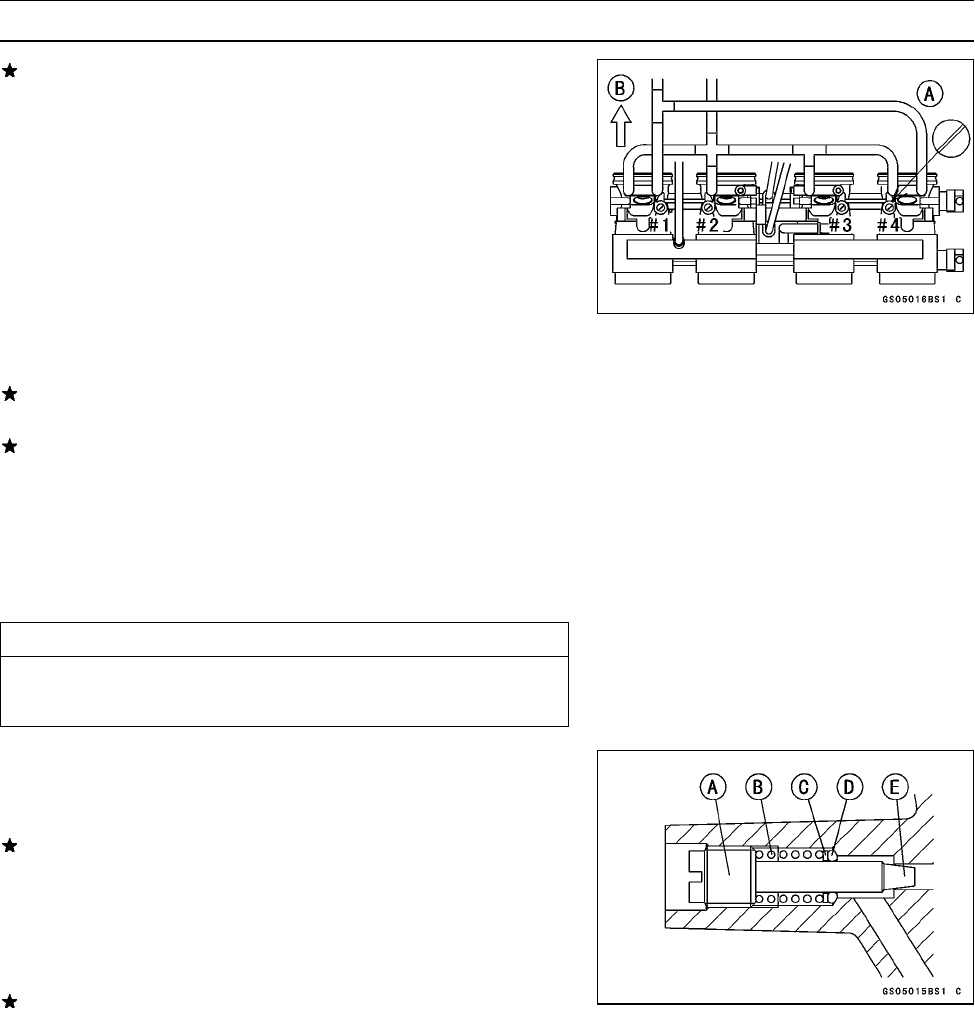

If any one vacuum measurement is out of the standard

measurement after synchronization, adjust the bypass

screws [A].

Front [B]

Special Tool - Pilot Screw Adjuster, C: 57001-1292

•

Adjust the lowest vacuum between #1 and #2 to the high-

est of #1 and #2.

•

Adjust the lowest vacuum between #3 and #4 to the high-

est of #3 and #4.

•

Open and close the throttle after each measurement and

adjust the idle speed as necessary.

•

Inspect the vacuums as before.

If all vacuums are within the specification, finish the en-

gine vacuum synchronization.

If any vacuum cannot be adjusted within the specification,

remove the bypass screws #1 ∼ #4 and clean them.

○

Turn in the bypass screw and count the number of turns

until it seats fully but not tightly. Record the number of

turns.

Torque - Bypass Screw: 0.2 N·m (0.02 kgf·m, 1.7 in·lb)

CAUTION

Do not over tighten them. They could be damaged,

requiring replacement.

○

Remove the bypass screw [A], spring [B], washer [C] and

O-ring [D].

○

Check the bypass screw and its hole for carbon deposits.

If any carbon accumulates, wipe the carbon off the bypass

screw and the hole, using a cotton pad penetrated with a

high-flash point solvent.

○

Replace the O-ring with a new one.

○

Check the tapered portion [E] of t he bypass screw for

wear or damage.

If the bypass screw is worn or damaged, replace it.

•

Turn in the bypass screw until it seats fully but not tightly.

Torque - Bypass Screw: 0.2 N·m (0.02 kgf·m, 1.7 in·lb)