CRANKSHAFT/TR ANSMISSION 9-17

Crankshaft and Connecting Rods

Connecting Rod Big End Bearing Insert/Crankpin

Wear

•

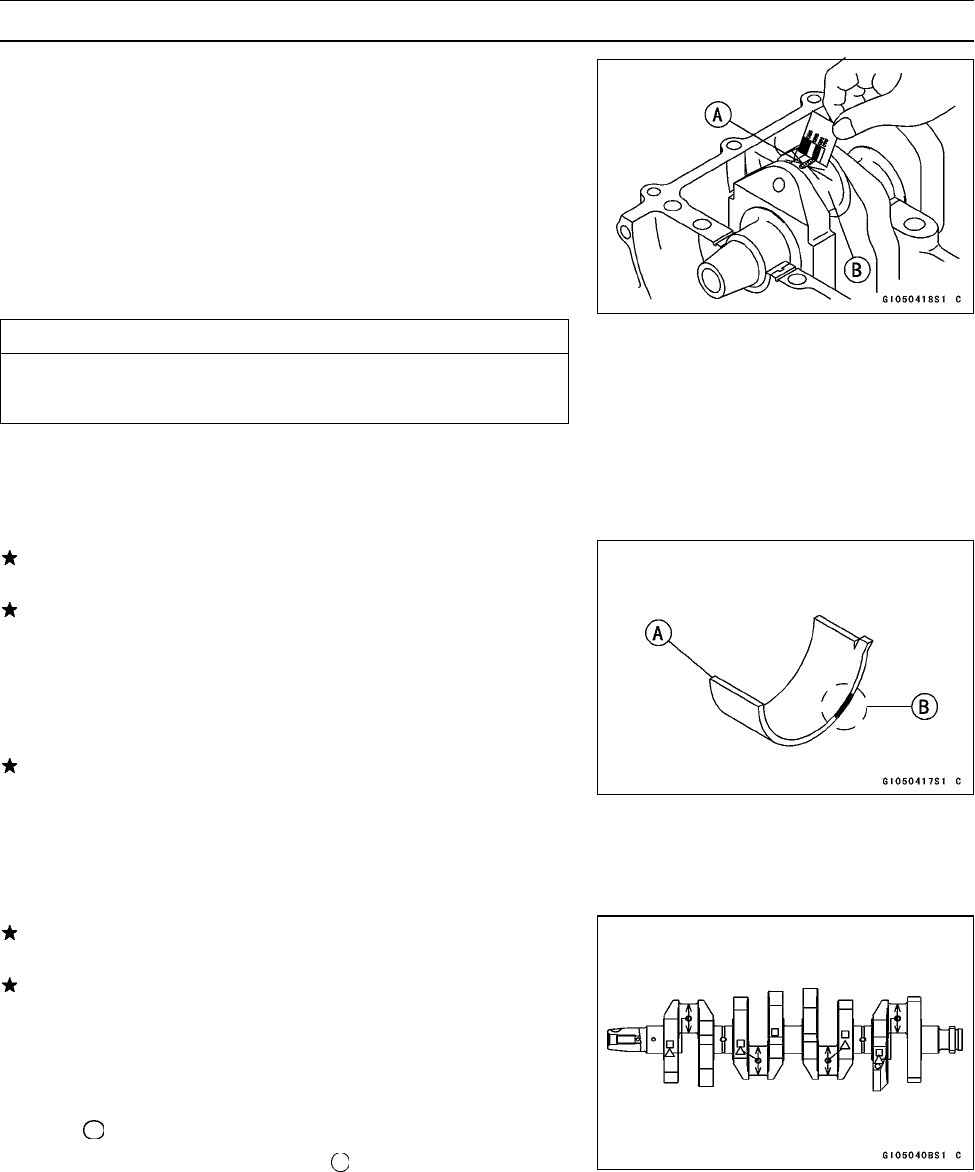

Measure the bearing insert/crankpin [B] clearance with

plastigage [A].

○

Tighten the big end nuts to the specified torque (see C on-

necting Rod Installation).

NOTE

○

Do not move the connecting rod and crankshaft during

clearance measurement.

CAUTION

After measurement, replace the connecting rod

bolts.

Connecting Rod Big End Bearing Insert/Crankpin Clearance

Standard: 0.041 ∼ 0.071 mm (0.0016 ∼ 0.0028 in.)

Service Limit: 0.11 mm (0.0043 in.)

If the clearance is within the standard, no bearing replace-

me

nt is required.

If the clearance is between 0.072 mm (0.00284 in.) and

the service limit (0.11 mm, 0.0043 in.), replace the bear-

in

g inserts [A] with inserts painted blue [B]. Check i n-

sert/crankpin clearance with the plastigage. The clear-

ance may exceed the standard slightly, but it must not be

l

ess than the minimum in order to avoid bearing seizure.

If the clearance exceeds the service limit, measure the

diameter of the crankpins.

Crankpin Diameter

Standard: 34.984 ∼ 35.000 mm (1.3773 ∼ 1.3780 in.)

Service Limit: 34.97 mm (1.3768 in.)

If any crankpin has worn past the service limit, replace the

crankshaft with a new one.

If the measured crankpin diameters are not less than the

service limit, but do not coincide with the original diameter

markings on the crankshaft, make new marks on it.

Crankpin Diameter Marks

None

34.984 ∼ 34.992 mm (1.3773 ∼ 1.3776 in.)

34.993 ∼ 35.000 mm (1.3777 ∼ 1.3780 in.)

∆: Crankpin Diameter Marks, " "ornomark.

•

Measure the connecting rod big end inside diameter, and

mark each connecting rod big end in accordance with the

inside diameter.

•

Tighten the connecting r od big end nuts to the specified

torque (see Connecting Rod Installation).

NOTE

○

The mark already on the big end should almost coincide

with the measurement.