3-82 FUEL SYSTEM (DFI)

Fuel Injectors

Removal/Installation

•

Refer to t he Throttle Body Assy Disassembly/Assembly.

Audible Inspection

•

Start the engine.

•

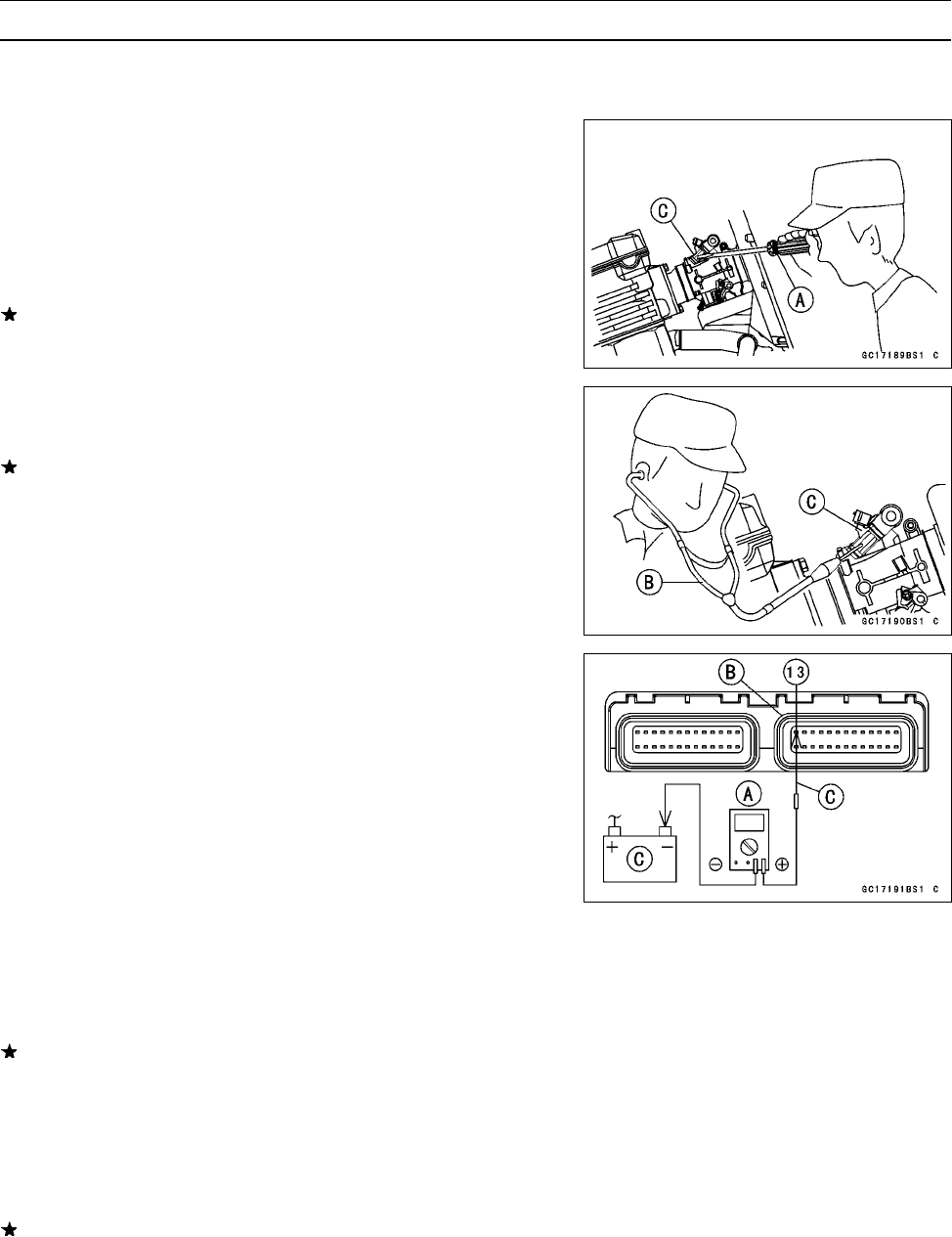

Apply the tip of a screwdriver [A] to the injector [C]. Put

the grip end onto your ear, and listen whether the injector

is clicking or not.

○

A sound scope [B] can also be used.

•

Do the same for the other injectors.

If all the injectors click at a regular intervals, the injectors

are good. The trouble may be related to the fuel line,

requiring fuel pressure inspection (see Fuel Line section

in this chapter).

○

The click interval becomes shorter as the engine speed

rises.

If any injector(s) doesn’t click, the DFI circuit or the injector

is suspect. Perform “Power Source Voltage Inspection”,

first.

Power Source Voltage Inspection

•

Remove the ECU (see ECU section). Do not disconnect

the ECU connector.

•

Connect a digital meter [A] to the ECU connector [B], us-

ing the needle adapter [C].

Special Tool - Needle Adapter Set: 57001–1457

○

Measure the power source voltage with the engine

stopped, and with the connector joined.

•

Turn the ignition switch ON.

Injector Power Source Voltage at ECU

Connections: Meter (+) → W/Y (terminal 13)

Meter (–) → Battery (–) Terminal

Service Limit: Voltage (12.6 V or more)

If the meter doesn’t read as specified, check the following.

Main Fuse 30A (see Electrical System chapter)

Fuel P ump Relay (see DFI Power Source section)

Power Source Wiring (see Wiring diagram below)

○

To check the W/R leads between the injector connector

and the fuel pump relay, remove the fuel tank (see Fuel

Tank Removal) and the seat cover (see Frame chapter).

If the power source voltage is normal, check the output

voltage of the injectors.