9-16 CRANKSHAFT/T RANSMISSION

Crankshaft and Connecting Rods

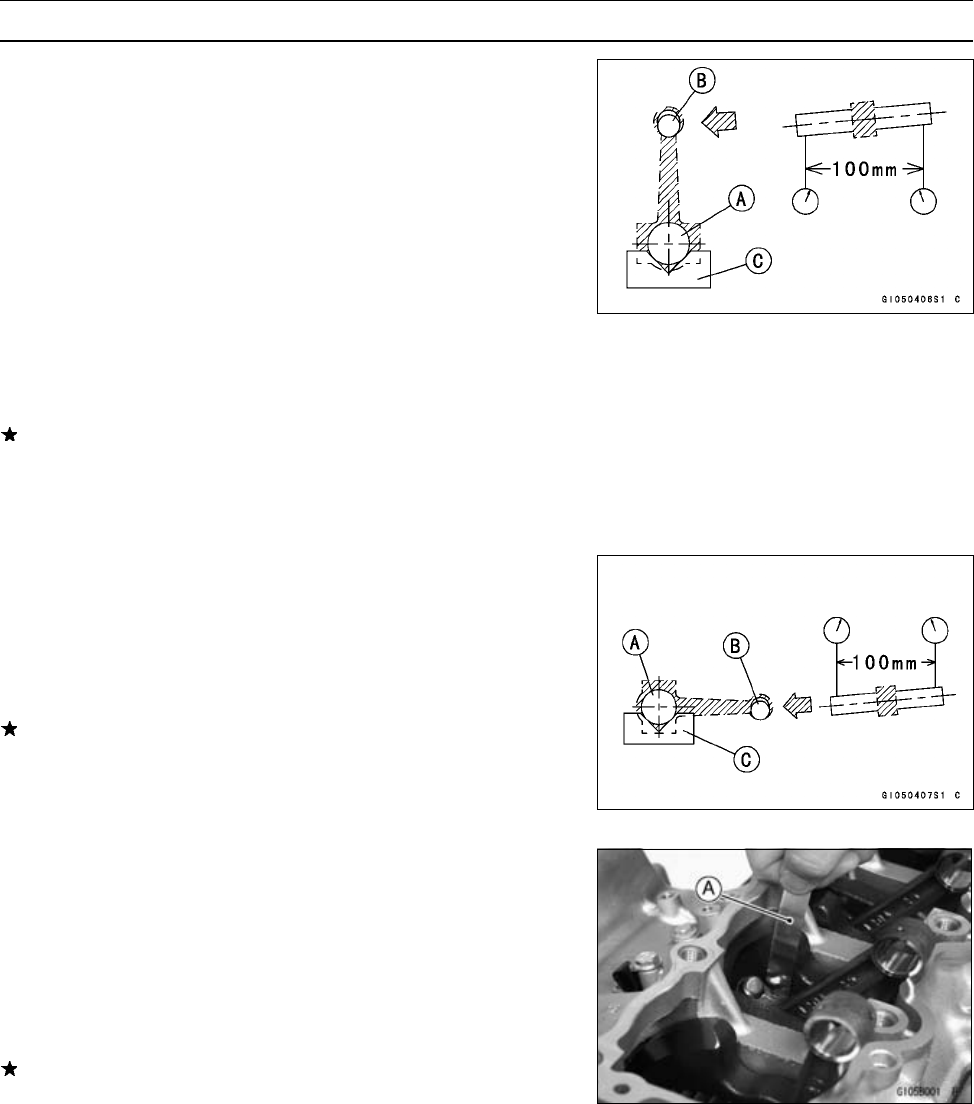

Connecting Rod Bend

•

Remove the connecting rod big end bearing inserts, and

reinst

all the connecting rod big end cap.

•

Select an arbor [A] of the same diameter as the connect-

ing rod big end, and insert the arbor through the connect-

ing ro

d big end.

•

Select an arbor of the same diameter as the piston pin and

more than 105 m m (4.13 in.) long, and insert the arbor [B]

thro

ugh the c onnecting rod small end.

•

On a surface plate, set the big-end arbor on V blocks [C].

•

With the connecting rod held vertically, use a height

gaug

e to measure the difference in the height of the

arbor above the surface plate over a 100 mm (3.94 in.)

length to determine the amount of connecting rod bend.

If c

onnecting rod bend exceeds the service limit, the con-

necting rod must be replaced.

Connecting Rod Bend

Service Limit: TIR 0.2/100 mm (0.008/3.94 in.)

Connecting Rod Twist

•

With the big-end arbor [A] still on V block [C], hold the con-

necting rod horizontally and measure the amount that the

arbor [B] varies from being parallel with the surface plate

over a 100 mm (3.94 in.) length of the arbor to determine

the amount of connecting rod twist.

If connecting rod twist exceeds the service limit, the con-

necting rod must be replaced.

Connecting Rod Twist

Service Limit: TIR 0.2/100 mm (0.008/3.94 in.)

Connecting Rod Big End Side Clearance

•

Measure connecting rod big end side clearance.

○

Insert a thickness gauge [A] between the big end and ei-

ther crank web to determine clearance.

Connecting Rod Big End Side Clearance

Standard: 0.13 ∼ 0.38 mm (0.0051 ∼ 0.0150 in.)

Service Limit: 0.58 mm (0.023 in.)

If the clearance exceeds the service limit, replace the con-

necting rod with new one and then check clearance again.

If clearance is too large after connecting rod replacement,

the crankshaft also must be replaced.