ENGINE TOP END 5-23

Valves

Valve Guide Installation

•

Apply oil to the valve guide outer surface before i nstalla-

tion.

•

Heat the area around the valve guide hole to about 120 ∼

150 °C (248 ∼ 302 °F).

•

Drive the valve guide in from the t op of the head using the

valve guide arbor. The flange stops the guide from going

in too far.

Spec

ial Tool -

Valv

e G uide A rbor,

4.5: 57001–1331

•

Wait until the cylinder head cools down and then ream the

valve guide with the valve guide reamer [A] even if the old

guide is reused.

○

Turn the reamer in a clockwise direction until the reamer

turns freely in the guide. Never turn the reamer counter-

clockwise or it will be dulled.

○

Once the guides are reamed they must be cleaned thor-

oughly.

Special Tool - Valve Guide Reamer, 4.5: 57001–1333

V

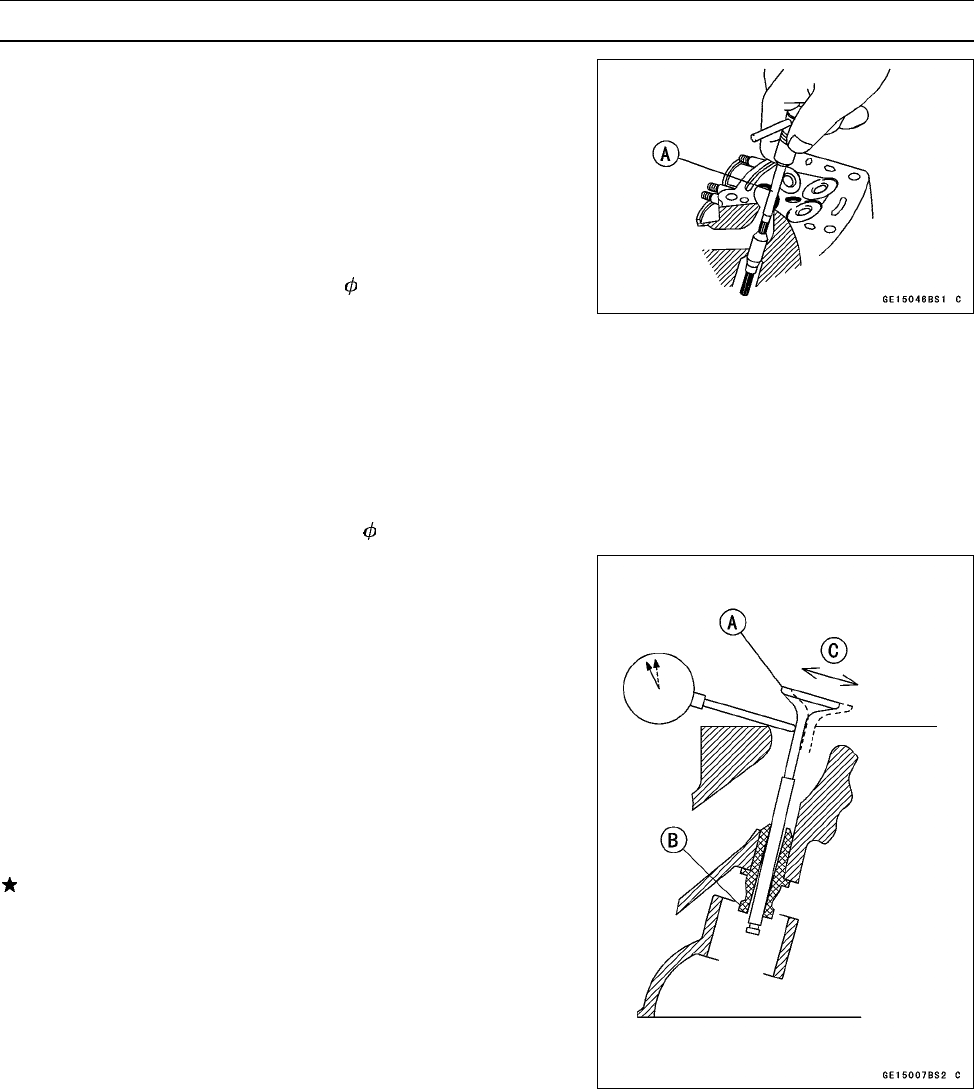

alve-to-Guide Clearance Measurement (Wobble

Method)

If a small bore gauge is not available, inspect the valve

g

uide wear by measuring the valve to valve guide clearance

with the wobble method as indicated below.

•

Insert a new valve [A] into the guide [B] and set a dial

gauge against the stem perpendicular to it as close as

possible to the cylinder head mating surface.

•

Move the stem back and forth [C] to measure valve/valve

guide clearance.

•

Repeat the measurement in a direction at a right angle to

the first.

If the reading exceeds the service limit, replace the guide.

NOTE

○

The reading is not actual valve/valve guide clearance

because the measuring point is above the guide.

Valve/Valve Guide Clearance (Wobble Method)

Inlet Exhaust

Standard:

0.03 ∼ 0.12 mm 0.09 ∼ 0.18 mm

(0.0012 ∼ 0.0047 in.) (0.0035 ∼ 0.0071 in.)

Service

0.33 mm 0.40 mm

Limit:

(0.013 in.) (0.016 in.)