10-10 WHEELS/TIRES

Wheels (Rims)

Axle Inspection

•

Visually inspect the front and rear axle for damages.

If the a

xle is damaged or bent, replace it.

•

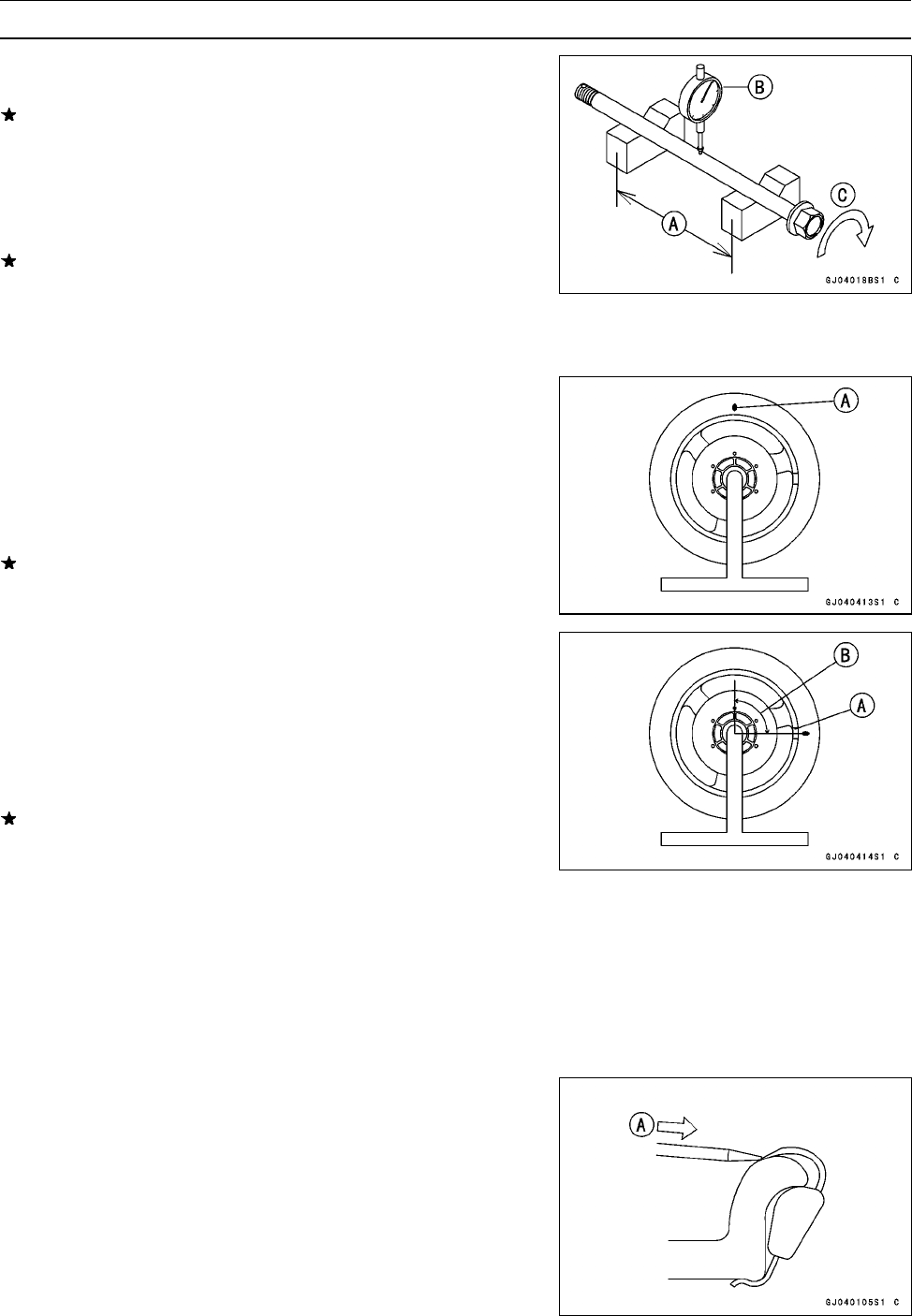

Place the axle in V blocks that are 100 mm (3.94 in.) [A]

apart, and set a dial gauge [B] on the axle at a point

halfw

ay between the blocks. Turn [C] the axle to mea-

sure the runout. The difference between the highest and

lowest dial readings is the amount of runout.

If ax

le runout exceeds the service limit, replace the axle.

Axle Runout/100 mm (3.94 in.)

Standard: TIR 0.05 mm (0.0020 in.) or less

Service Limit: TIR 0.2 mm (0.008 in.)

Balance Inspection

•

Remove the wheel.

•

Support the wheel so that it can be spun freely.

•

Spin the wheel lightly, and mark [A] the wheel at the top

when the wheel stops.

○

Repeat this procedure several times. If the wheel stops

of its own accord in various positions, it is well balanced.

If the wheel always stops in one position, adjust the wheel

balance.

Balance Adjustme nt

•

If the wheel always stops in one position, provisionally

attach a balance weight [A] on the rim at the m arking using

adhesive tape.

•

Rotate the wheel 1/4 t urn [B], and see whether or not the

wheel stops in this position. If it does, the correct balance

weight is being used.

If the wheel rotates and the weight goes up, replace the

weight with the next heavier size. If the w heel rotates and

the weight goes down, replace the weight with the next

lighter size. Repeat these steps until the wheel remains

at rest after being rotated 1/4 turn.

•

Rotate the wheel another 1/4 turn and then another 1/4

turn to see i f the wheel is correctly balanced.

•

Repeat the entire procedure as many times as necessary

to achieve correct wheel balance.

•

Permanently install the balance weight.

Balance Weight Remov al

(a) When the tire is not on the rim.

•

Push [A] the blade portion toward the outside with a regu-

lar tip screw-driver, and slip the weight off the rim flange.

•

Discard the used balance weight.