ELECTRICAL SYSTEM 16-39

Ignition System

Crankshaft Sensor Resistance: 375 ∼ 565 Ω

•

Using the highest resistance range of the tester, measure

the resistance between the crankshaft sensor leads and

chassis ground.

Any tester reading less than infinity (∞) indicates a short,

necessitating replacement of the crankshaft sensor as-

sembly.

Crankshaft Sensor Peak Voltage Inspection

NOTE

○

Be sure the battery is fully charged.

○

Using the peak voltage adapter is a more reliable way

to determine the condition of the crankshaft sensor than

crankshaft sensor internal resistance m easurements.

•

Remove:

Frame Cover (see Frame chapter)

Crankshaft Sensor Lead Connector (see Crankshaft

Sensor Removal)

•

Set the hand tester [B] to the × 10 V DC range, and con-

nect it a commercially available peak voltage adapter [A]

as shown in the diagram.

•

Connect the black lead of the adapter to black lead and

red lead to yellow lead in the crankshaft sensor connector

[C].

•

T urn the ignition switch and engine stop switch on.

•

Pushing the starter button, turn the engine 4 ∼ 5sec-

onds with the transmission gear in neutral to measure the

crankshaft sensor peak voltage.

•

Repeat the m easurement 5 or m ore times.

Crankshaft Sensor Peak Voltage

Standard:

1.9 V or more

Special Tool - Hand Tester: 57001–1394

Recommended Tool- Peak Voltage Adapter

Type: KEK-54-9-B

Brand: KOWA SEIKI

If the tester reading is not specified one, check the crank-

shaft sensor.

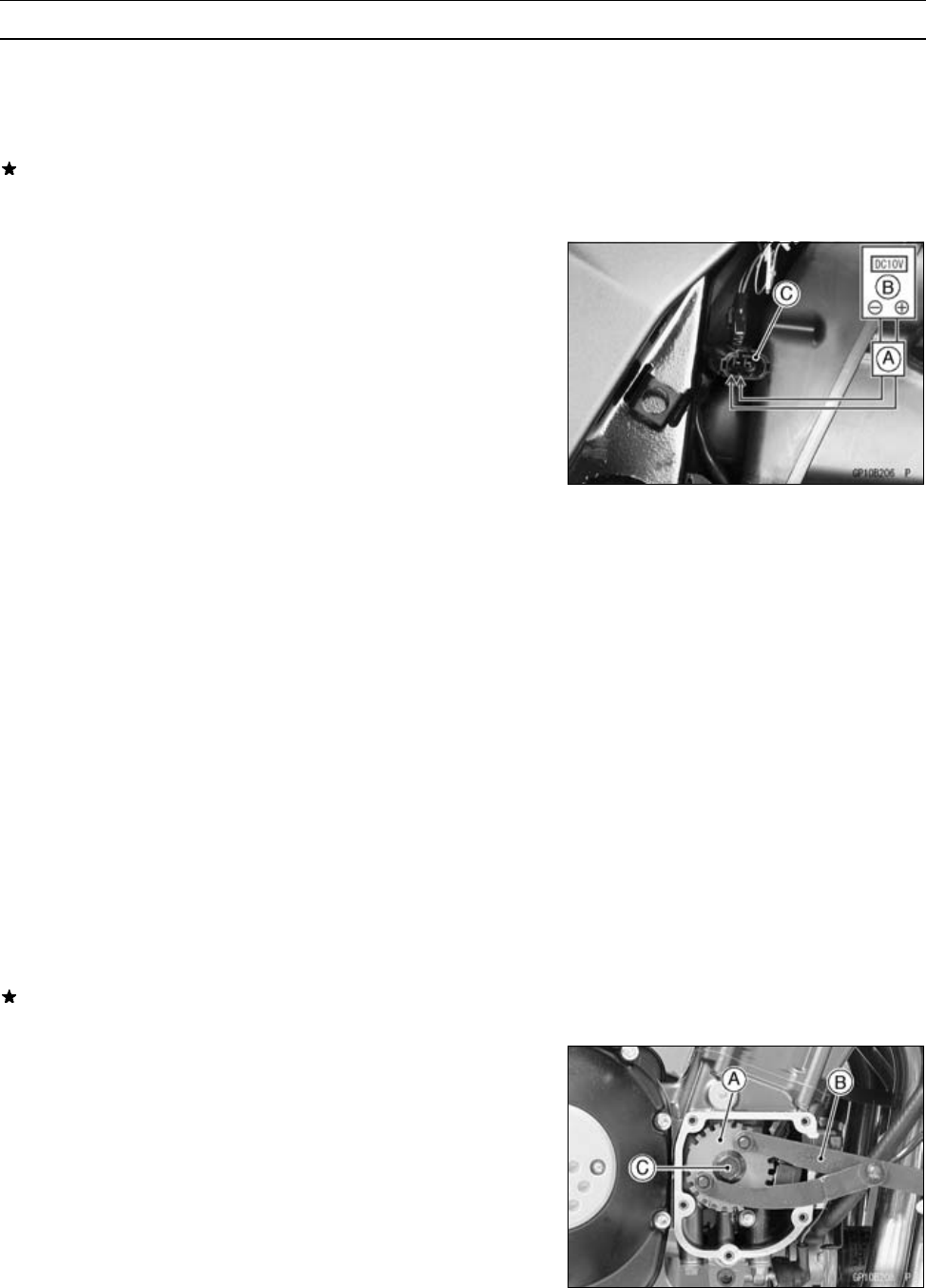

Timing Rotor Removal

•

Remove the crankshaft sensor cover (see Crankshaft

Sensor Removal)

•

Remove the timing rotor [A].

○

Holding the timing rotor with the flywheel and pulley holder

[B] and unscrew the bolt [C].

Special Tool - Flywheel and Pulley Holder : 57001–1343

Timing Rotor Installation

•

Fit the rotor to the crankshaft.

•

Tighten the rotor bolt.

Torque - Timing Rotor Bolt : 39 N·m (4.0 kgf·m, 29 ft·lb)

•

Install the crankshaft sensor cover ( see Crankshaft Sen-

sor Installation).