The hose ends can then be unclipped from

the brackets. The mounting brackets,

particularly on the body frame, are not very

heavy gauge and care must be taken not to

wrench them off (photo).

4 With the flexible hose removed, examine

the internal bore. If it is blown through first, it

should be possible to see through it. Any

specks of rubber which come out, or signs of

restriction in the bore, mean that the inner

lining is breaking up and the pipe must be

renewed.

5 When refitting the flexible hoses check they

cannot be under tension, or rub, when the

wheels are at the full range of suspension or

steering movement.

6 Bleed the system (see Section 12) on

completion.

Rigid pipes

7 Inspect the condition of the braking system

rigid pipelines at frequent intervals. They must

be cleaned off and examined for any signs of

dents (or other percussive damage) and rust

and corrosion. Rust and corrosion should be

scraped off and, if the depth of pitting in the

pipes is significant, they will need renewal.

This is particularly likely in those areas

underneath the car body and along the rear

axle where the pipes are exposed to the full

force of road and weather conditions.

8 Rigid pipe removal is usually straight-

forward. The unions at each end are undone,

the pipe and union pulled out, and the centre

sections of the pipe removed from the body

clips where necessary. Underneath the car,

exposed unions can sometimes be very tight.

As one can use only an open-ended spanner

and the unions are not large, burring of the

flats is not uncommon when attempting to

undo them. For this reason, a self-locking grip

wrench (Mole) is often the only way to remove

a stubborn union.

9 Rigid pipes which need renewal can usually

be purchased at any garage where they have

the pipe, unions and special tools to make

them up. All they need to know is the total

length of the pipe, the type of flare used at

each end with the union, and the length and

thread of the union. Fiat is metric, remember.

10 Fitting your new pipes is a straightforward

reversal of the removal procedure. If the rigid

pipes have been made up, it is best to get all

the sets bends in them before trying to fit

them. Also, if there are any acute bends ask

your supplier to put these in for you on a tube

bender. Otherwise, you may kink the pipe and

thereby restrict the bore area and fluid flow.

11 Bleed the system (see Section 12) on

completion.

12 Hydraulic system -

bleeding

3

1 If the master cylinder or the pressure

regulating valve has been disconnected and

reconnected then the complete system (both

circuits) must be bled.

2 If a component of one circuit has been

disturbed then only that particular circuit need

be bled.

3 The two disc brakes comprise the front

circuit and the two rear brakes the rear circuit.

4 Unless the pressure bleeding method is

being used, do not forget to keep the fluid

level in the master cylinder reservoir topped

up to prevent air from being drawn into the

system which would make any work done

worthless.

5 Before commencing operations, check that

all system hoses and pipes are in good

condition with all unions tight and free from

leaks.

6 Take great care not to allow hydraulic fluid

to come into contact with the vehicle

paintwork as it is an effective paint stripper.

Wash off any spilled fluid immediately with

cold water.

7 As the system on 55 and 70 models

incorporates a vacuum servo, destroy the

vacuum by giving several applications of the

brake pedal in quick succession. The car

should be loaded with enough weight to

actuate the pressure regulating valve before

bleeding commences.

Bleeding - two man method

8 Gather together a clean glass jar and a

length of rubber or plastic tubing which will be

a tight fit on the brake bleed screws (photo).

9 Engage the help of an assistant.

10 Push one end of the bleed tube onto the

flrst bleed screw and immerse the other end

of the glass jar which should contain enough

hydraulic fluid to cover the end of the tube.

11 Open the bleed screw one half a turn and

have your assistant depress the brake pedal

fully then slowly release it. Tighten the bleed

screw at the end of each pedal downstroke to

obviate any chance of air or fluid being drawn

back into the system.

12 Repeat this operation until clean hydraulic

fluid, free from air bubbles, can be seen

coming through into the jar.

13 Tighten the bleed screw at the end of a

pedal downstroke and remove the bleed tube.

Bleed the remaining screws in a similar way.

Bleeding - using a one way

valve kit

14 There are a number of one-man, one-way

brake bleeding kits available from motor

accessory shops. It is recommended that one

of these kits is used wherever possible as it will

greatly simplify the bleeding operation and also

reduce the risk of air or fluid being drawn back

into the system quite apart from being able to

do the work without the help of an assistant.

15 To use the kit, connect the tube to the

bleedscrew and open the screw one half a

turn.

16 Depress the brake pedal fully and slowly

release it. The one-way valve in the kit will

prevent expelled air from returning at the end

of each pedal downstroke. Repeat this

operation several times to be sure of ejecting

all air from the system. Some kits include a

translucent container which can be positioned

so that the air bubbles can actually be seen

being ejected from the system.

17 Tighten the bleed screw, remove the tube

and repeat the operations on the remaining

brakes.

18 On completion, depress the brake pedal. If it

still feels spongy repeat the bleeding operations

as air must still be trapped in the system.

Bleeding - using a pressure

bleeding kit

19 These kits too are available from motor

accessory shops and are usually operated by

air pressure from the spare tyre.

Braking system 8•7

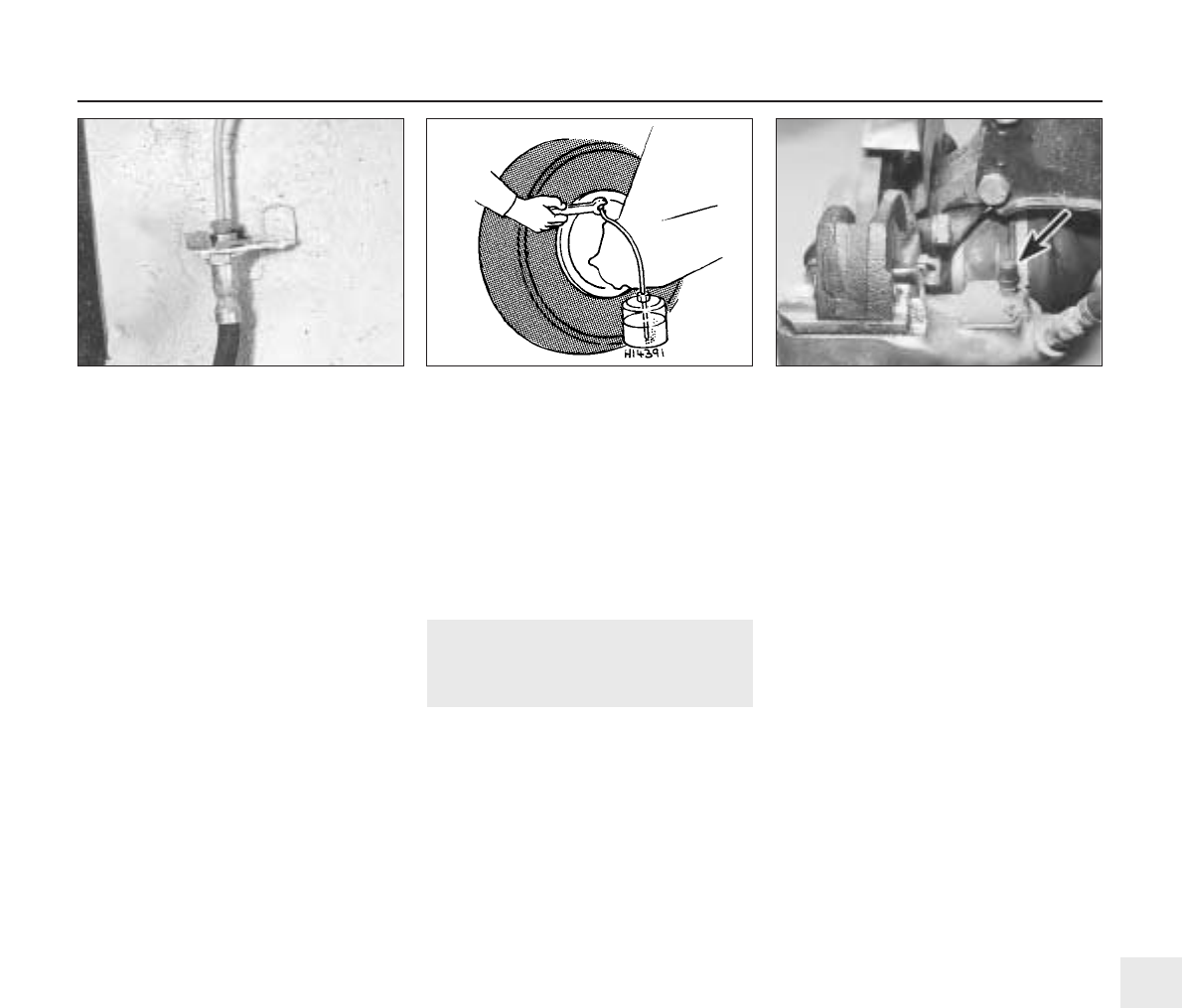

12.8 Caliper bleed screw with dust cap

fitted

Fig. 8.12 Bleeding a rear wheel cylinder

(Sec 12)

11.3 Front hydraulic hose bracket

8