new oil seal, ensuring that it is correctly

orientated, and drive it squarely into position.

149 Refit all disturbed components.

Flywheel - removal,

inspection and refitting #

150 If not already done, remove the clutch as

described in Chapter 5.

151 Prevent the flywheel from turning by

jamming the ring gear teeth, or by bolting a

strap between the flywheel and the cylinder

block.

152 Make alignment marks on the flywheel

and the end of the crankshaft, so that the

flywheel can be refitted in its original position.

153 Unscrew the securing bolts and remove

the washer plate, then withdraw the flywheel.

Do not drop it, it is very heavy.

154 With the flywheel removed, the ring gear

can be examined for wear and damage.

155 If the ring gear is badly worn or has

missing teeth it should be renewed. The old

ring gear can be removed from the flywheel by

cutting a notch between two teeth with a

hacksaw and then splitting it with a cold

chisel. Wear eye protection when doing this.

156 Fitting of a new ring gear requires heating

the ring to a temperature of 80ºC (176ºF). Do

not overheat, or the hard-wearing properties

will be lost. The gear has a chamfered inner

edge which should fit against the shoulder on

the flywheel. When hot enough, place the gear

in position quickly, tapping it home if

necessary, and let it cool naturally without

quenching in any way.

157 Ensure that the mating faces are clean,

then locate the flywheel on the rear of the

crankshaft, aligning the previously made

marks on the flywheel and crankshaft.

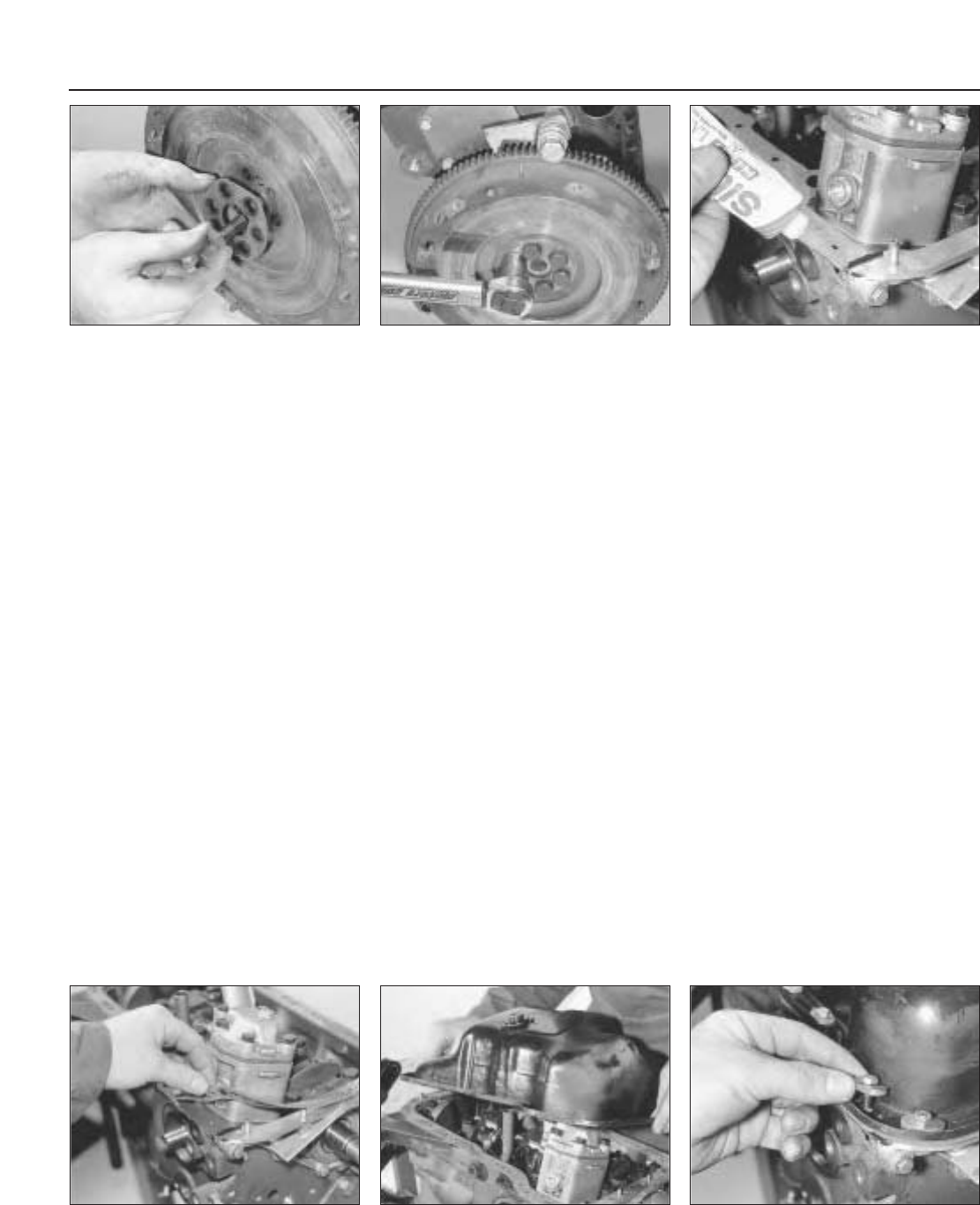

158 Fit the washer plate, and insert the

securing bolts, then prevent the flywheel from

turning as described in paragraph 151 whilst

the bolts are tightened progressively to the

specified torque setting in a diagonal

sequence (photos).

159 If applicable, refit the clutch as described

in Chapter 5.

Sump -

removal and refitting ¡

160 Drain the engine oil from the sump as

described in Chapter 1.

161 Disconnect the lead from the engine oil

level sensor in the sump.

162 Unscrew and remove the bolts retaining the

gear linkage mounting bracket (where applicable)

and the clutch housing lower cover bolts.

Remove the cover from the clutch housing.

163 Unscrew and remove the sump retaining

bolts and nuts and lower the sump from the

crankcase. Recover the gasket.

164 Clean all traces of old gasket from the

sump, crankcase and both oil seal housing

mating surfaces.

165 Commence reassembly by applying

sealing compound (FIAT No. 5882442 or

equivalent) to the joints between the

crankshaft front and rear oil seal housings and

the mating face of the crankcase (photo).

166 Locate the new gasket in position on the

crankcase then fit the sump. As it is fitted it

will need to be twisted to avoid fouling the oil

pump unit. Refit the retaining bolts and nuts

and tighten them to the specified torque

(photos).

167 Check that the sump drain plug is refitted

and fully tightened. If the engine is in the car,

top up the engine oil level.

Oil pump - removal,

checking and refitting ™

168 Drain the engine oil and remove the

sump as described in the previous

sub-Section.

169 Unscrew the retaining bolts then

withdraw the oil pump and intake pipe/filter

from its location within the crankcase.

Remove the gasket.

170 If oil pump wear is suspected, first check

the cost and availability of new parts and the

cost of a new pump. Then examine the pump

as described below and decide whether

renewal or repair is the best course of action.

171 Unscrew the three securing bolts and

remove the oil pump cover (photo). Note that

as the cover is removed, the oil pressure relief

valve components will be released.

172 Recover the oil pressure relief valve,

spring and spring seat.

13•46 Supplement: Revisions and information on later models

7B.166C . . . and insert the retaining bolts7B.166B . . . refit the sump . . .7B.166A Locate the new gasket . . .

7B.165 Apply sealant to the front oil seal

housing/cylinder block joint

7B.158B . . . tighten the bolts to the

specified torque

7B.158A Locate the flywheel, washer plate

and bolts . . .