inhibitor should be used. Again, a reputable

make giving full protection must be chosen

and renewed every two years. Inhibitors with

dyes are useful for finding leaks, and on some

makes the dye shows when the inhibiting

ability is finished.

4 Thermostat -

removal, testing and refitting

1

1 The thermostat assembly is mounted on the

flywheel end of the cylinder block.

2 Unfortunately, the thermostat/housing is a

complete unit and failure of the thermostat will

necessitate the purchase of the complete

component (photo).

3 If the thermostat/housing is removed from

the engine, it can be suspended in water and

the water heated to check out its opening

temperature. Movement of the thermostat

valve can be observed to some extent

through the openings in the housing.

4 When refitting, always use a new gasket at

its mounting face (photo).

5 Radiator fan thermostatic

switch - removal, checking

and refitting

1

1 Drain the cooling system.

2 If the thermostatic switch is being removed

because the fan is not operating and the

switch is suspect, check the fan fuse first,

before removing the switch.

3 To remove the switch, disconnect the leads

from the terminals and unscrew the switch.

4 Connect a test bulb and battery across the

switch terminals and then immerse the

sensing part of the switch in a container of

water. Heat the water and, using a

thermometer, check the temperature of the

water when the bulb lights up, indicating the

switch is functioning. The switch should

operate at approximately 194ºF (90ºC). Allow

the water to cool and check that the switch

cuts out at 185ºF (85ºC). Renew a faulty

switch.

5 Refitting of the switch is the reverse of the

removal procedure. Always fit a new O-ring on

the switch.

6 Radiator fan -

removal and refitting

1

1 Disconnect the electrical leads from the

radiator fan motor.

2 Unbolt the fan mounting struts from the

radiator and lift the complete assembly away.

3 Refitting is a reversal of removal.

7 Radiator -

removal and refitting

1

1 Drain the cooling system.

2 Disconnect the electrical leads from the

radiator fan motor and thermostatic switch.

3 Disconnect the coolant hoses from the

radiator (photos).

4 Release the clips from the top of the

radiator and withdraw the radiator complete

with fan from the engine compartment

(photos).

5 The radiator is of combined plastic/metal

construction and any repair should be left to

specialists. In an emergency however, minor

leaks from the radiator may be cured by using

a radiator sealant with the radiator in situ.

6 Refitting is a reversal of removal. Fill the

cooling system as described in Section 2.

8 Drivebelt -

tensioning and renewal

1

1 The drivebelt for the alternator and coolant

pump is correctly tensioned if it deflects

through 10.0 mm (0.39 in) under moderate

thumb pressure at the mid point of the longest

run of the belt.

2 To tighten the belt, release the mounting

and adjuster nuts on the alternator and prise

the alternator away from the engine. Tighten

the nuts when the belt is taut and then

re-check the tension as previously described.

Never over-tension a belt or the coolant pump

or alternator bearings may be damaged.

3 Check the condition of the belt at regular

intervals. If frayed or cracked, renew it in the

following way.

4 Release the alternator mounting and

adjuster nuts and push the alternator fully in

Cooling and heating systems 2•3

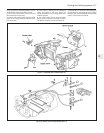

7.3A Radiator top hose4.4 Fitting thermostat housing

(1116 cc engine)

4.2 Thermostat housing

7.4B Removing radiator/fan assembly7.4A Radiator fixing clip7.3B Radiator hose to thermostat housing

2