Cylinder head - removal and refitting

Sump pan - removal and refitting

Pistons/connecting rods - removal and

refitting

Oil pump - removal and refitting

Engine mountings - renewal

1116 cc and 1301 cc engines

Valve clearances - checking and adjusting

Camshaft and camshaft carrier - removal

and refitting

Timing belt - removal and refitting

Cylinder head - removal and refitting

Sump pan - removal and refitting

Oil pump - removal and refitting

Pistons/connecting rods - removal and

refitting

Engine mountings - renewal

Part 2:

903 cc engine

5 Valve clearances -

adjustment

2

1 Adjust the valves when the engine is cold.

2 Unbolt and remove the rocker cover.

3 It is important that the clearance is set

when the cam follower of the valve being

adjusted is on the heel of the cam (ie;

opposite the peak). This can be done by

carrying out the adjustments in the following

order, which also avoids turning the

crankshaft more than necessary.

4 Turn the crankshaft either using a spanner

on the pulley nut or by raising a front

roadwheel, engaging a gear (3rd or 4th) and

turning the wheel in the forward direction of

travel. It will be easier to turn the engine if the

spark plugs are first removed.

Valve fully open Check and adjust

Valve No. 8 EX Valve No. 1 EX

Valve No. 6 IN Valve No. 3 IN

Valve No. 4 EX Valve No. 5 EX

Valve No. 7 IN Valve No. 2 IN

Valve No. 1 EX Valve No. 8 EX

Valve No. 3 IN Valve No. 6 IN

Valve No. 5 EX Valve No. 4 EX

Valve No. 2 IN Valve No. 7 IN

5 Count the valves from the timing cover end

of the engine.

6 Remember, the inlet and exhaust valve

clearances are different.

7 Insert the appropriate feeler gauge between

the end of the valve stem and the rocker arm.

It should be a stiff sliding fit (photo).

8 If the clearance is incorrect, release the

rocker arm adjuster screw locknut using a ring

spanner. Turn the adjuster screw using a

small open-ended spanner, but tie something

to it in case it is inadvertently dropped

through one of the pushrod holes.

9 Once the clearance is correct, tighten the

locknut without moving the position of the

adjuster screw.

10 Repeat the operations on the remaining

seven valves.

11 Re-check all the clearances. Make sure

that the rocker cover gasket is in good

condition and fit the rocker cover.

6 Timing chain and sprockets

- removal and refitting

3

1 Remove the alternator drivebelt as

described in Chapter 2.

2 Unscrew and remove the crankshaft pulley

nut.

3 Disconnect the hoses from the fuel pump.

4 Unbolt and remove the fuel pump with

spacer and rod.

5 Support the engine on a hoist or under the

sump and disconnect and remove the

right-hand mounting. Then unscrew and

remove the timing cover bolts. The base of

the cover is secured by the front two sump

pan studs. Unbolt and lower the front end of

the sump. Avoid breaking the gasket. Remove

the timing cover.

6 Undo and remove the camshaft sprocket

securing bolt; this will also release the fuel

pump drive cam from the end of the camshaft.

Note the timing marks on the camshaft and

crankshaft sprockets.

7 Using two tyre levers, carefully ease the two

sprockets forwards away from the crankcase.

Lift away the two sprockets and timing chain.

8 Remove the Woodruff key from the

crankshaft nose with a pair of pliers and note

how the channel in the pulley is designed to fit

over it. Place the Woodruff key in a container

as it is a very small part and can easily

become lost. The camshaft sprocket is

located on the camshaft by a dowel peg.

Refitting

9 Fit the Woodruff key to the front of the

crankshaft.

10 Tap the crankshaft sprocket onto the front

of the crankshaft.

11 Turn the sprocket so that the Woodruff

key is uppermost.

12 Turn the camshaft until it is in such a

position that if the sprocket was fitted the

dimple timing mark on the sprocket would be

nearest to and in alignment with, the one on

the crankshaft sprocket.

903 cc engine 1•9

5.7 Adjusting a valve clearance

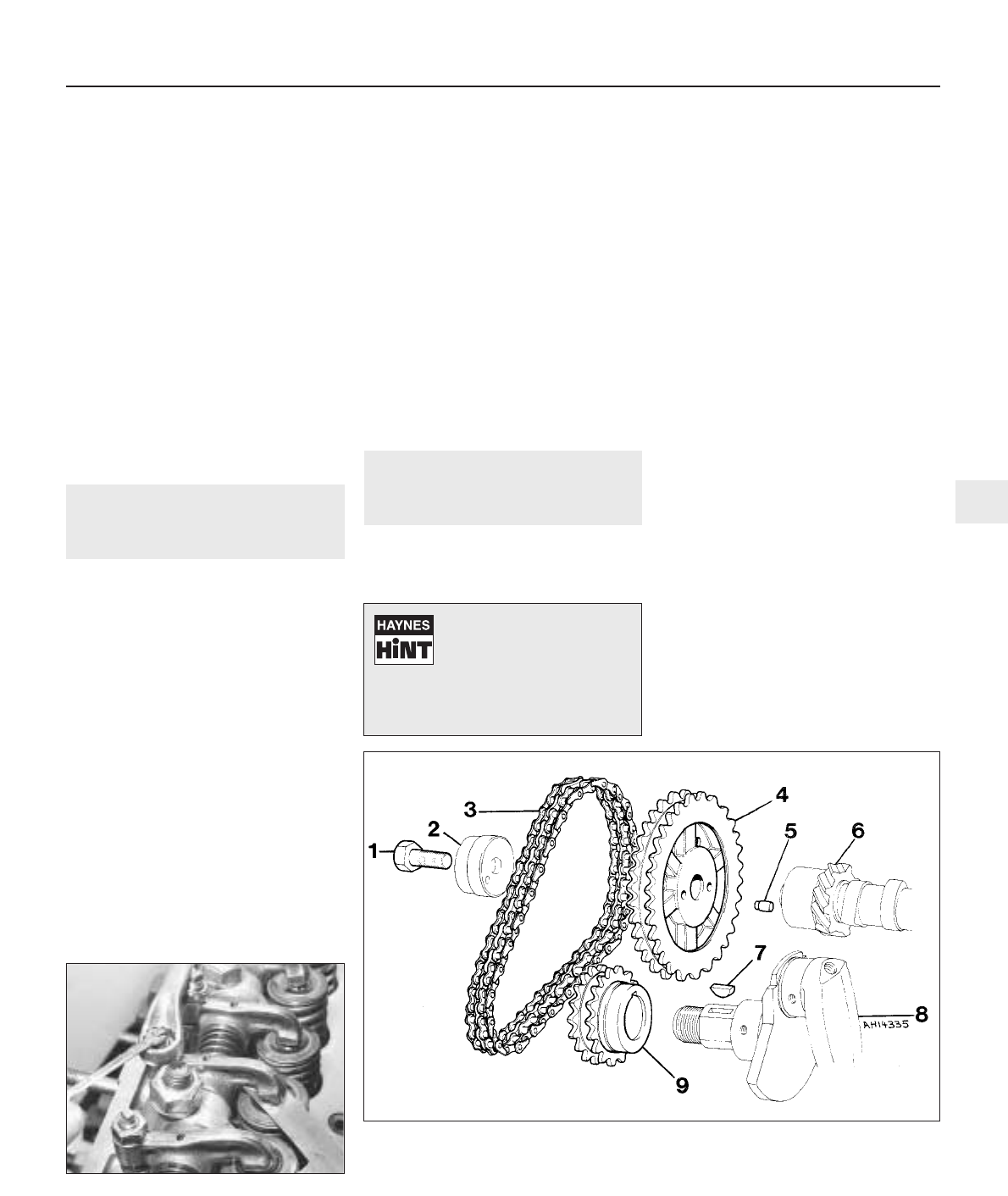

1 Sprocket retaining bolt

2 Fuel pump eccentric cam

3 Timing chain

4 Camshaft sprocket

5 Sprocket locating dowel

6 Camshaft

7 Woodruff key

8 Crankshaft

9 Crankshaft sprocket

Fig. 1.6 Timing chain and sprockets (Sec 6)

1

To prevent the crankshaft

rotating, either select a gear

and have an assistant apply

the footbrake hard or

remove the starter motor and lock the

ring gear teeth with a large cold chisel

or screwdriver.