this type is used and the engine is in good

condition, the spark plugs should not need

attention between scheduled replacement

intervals. Spark plug cleaning is rarely

necessary and should not be attempted unless

specialised equipment is available as damage

can easily be caused to the firing ends.

2 At the specified intervals, the plugs should

be renewed. The condition of the spark plug

will also tell much about the overall condition

of the engine.

3 If the insulator nose of the spark plug is

clean and white, with no deposits, this is

indicative of a weak mixture, or too hot a plug.

(A hot plug transfers heat away from the

electrode slowly - a cold plug transfers it away

quickly.)

4 If the tip of the insulator nose is covered

with sooty black deposits, then this is

indicative that the mixture is too rich. Should

the plug be black and oily, then it is likely that

the engine is fairly worn, as well as the mixture

being too rich.

5 The spark plug gap is of considerable

importance, as, if it is too large or too small

the size of the spark and its efficiency will be

seriously impaired. The spark plug gap should

be set to the gap shown in the Specifications

for the best results.

6 To set it, measure the gap with a feeler

gauge, and then bend open, or close, the

outer plug electrode until the correct gap is

achieved. The centre electrode should never

be bent as this may crack the insulation and

cause plug failure, if nothing worse.

7 When fitting new plugs, check that the plug

seats in the cylinder head are quite clean.

Refit the leads from the distributor in the

correct firing order, which is 1-3-4-2; No 1

cylinder being the one nearest the flywheel

housing (903 cc) or timing belt (1116 or

1301 cc). The distributor cap is marked with

the HT lead numbers to avoid any confusion.

Simply connect the correctly numbered lead

to its respective spark plug terminal (photo).

12 Ignition switch -

removal and refitting

1

1 Access to the steering column lock/ignition

switch is obtained after removing the steering

wheel and column shrouds (Chapter 10) and

the column switch unit (Chapter 9).

2 In the interest of safety, disconnect the

battery negative lead and the ignition switch

wiring plug (photo).

3 Insert the ignition key and turn to the STOP

position (photo).

4 Pull the two leads from the switch.

5 Turn the ignition key to MAR.

6 Using a screwdriver depress the retaining

tabs (1) (Fig. 4.16) and release the ignition

switch.

7 Set the switch cam (2) so that the notches

(3) are in alignment.

8 Insert the switch into the steering lock and

engage the retaining tabs.

9 Turn the ignition key to STOP and connect

the two leads.

10 Reconnect the battery and refit the

steering wheel, switch and shrouds.

11 Removal and refitting of the steering

column lock is described in Chapter 10.

Note: The ignition key is removable when set

to the STOP position and all electrical circuits

will be off. If the interlock button is pressed,

the key can be turned to the PARK position in

order that the parking lamps can be left on

and the steering lock engaged, but the key

can be withdrawn.

4•8 Ignition system

Fig. 4.16 Typical ignition switch (Sec 12)

1 Retaining tabs 3 Alignment notches

2 Switch cam 4 Locating projection

12.3 Ignition key positions

1 AVV (Start) 3 Stop (Lock)

2 Park (Parking lights on) 4 MAR (Ignition)

12.2 Ignition switch and lock

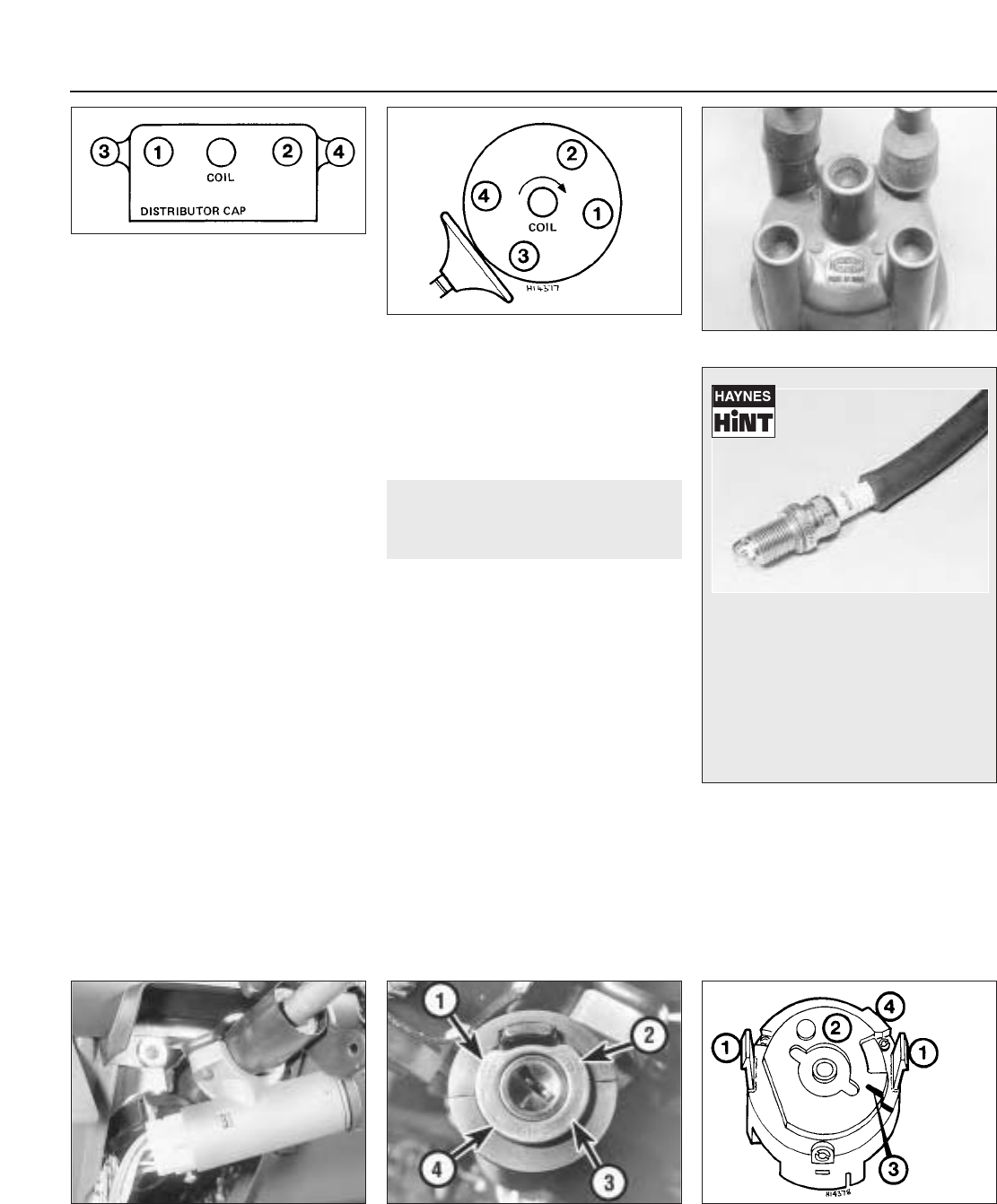

11.7 Distributor cap HT lead markings

Fig. 4.15 Spark plug connections on

1116 cc and 1301 cc engines (Sec 11)

Fig. 4.14 Spark plug connections on

903 cc engine (Sec 11)

It’s often difficult to insert spark plugs

into their holes without cross-threading

them. To avoid this possibility, fit a

short piece of rubber hose over the end

of the spark plug. The flexible hose

acts as a universal joint, to help align

the plug with the plug hole. Should the

plug begin to cross-thread, the hose

will slip on the spark plug, preventing

thread damage.