4-18 ENGINE TOP END

NOTE

ODo not use a wire brush to remove the metal particles

from the cutter. It will take off the diamond particles.

4. Setting the valve seat cutter holder in position, operate

the cutter in one hand. Do not apply too much force

to the diamond portion.

NOTE

0 Prior to grinding, apply engine oil to the cutter and

during the operation, wash off any ground particles

sticking to the cutter with washing oil.

5. After use, wash it with washing oil and apply thin layer

of engine oil before storing.

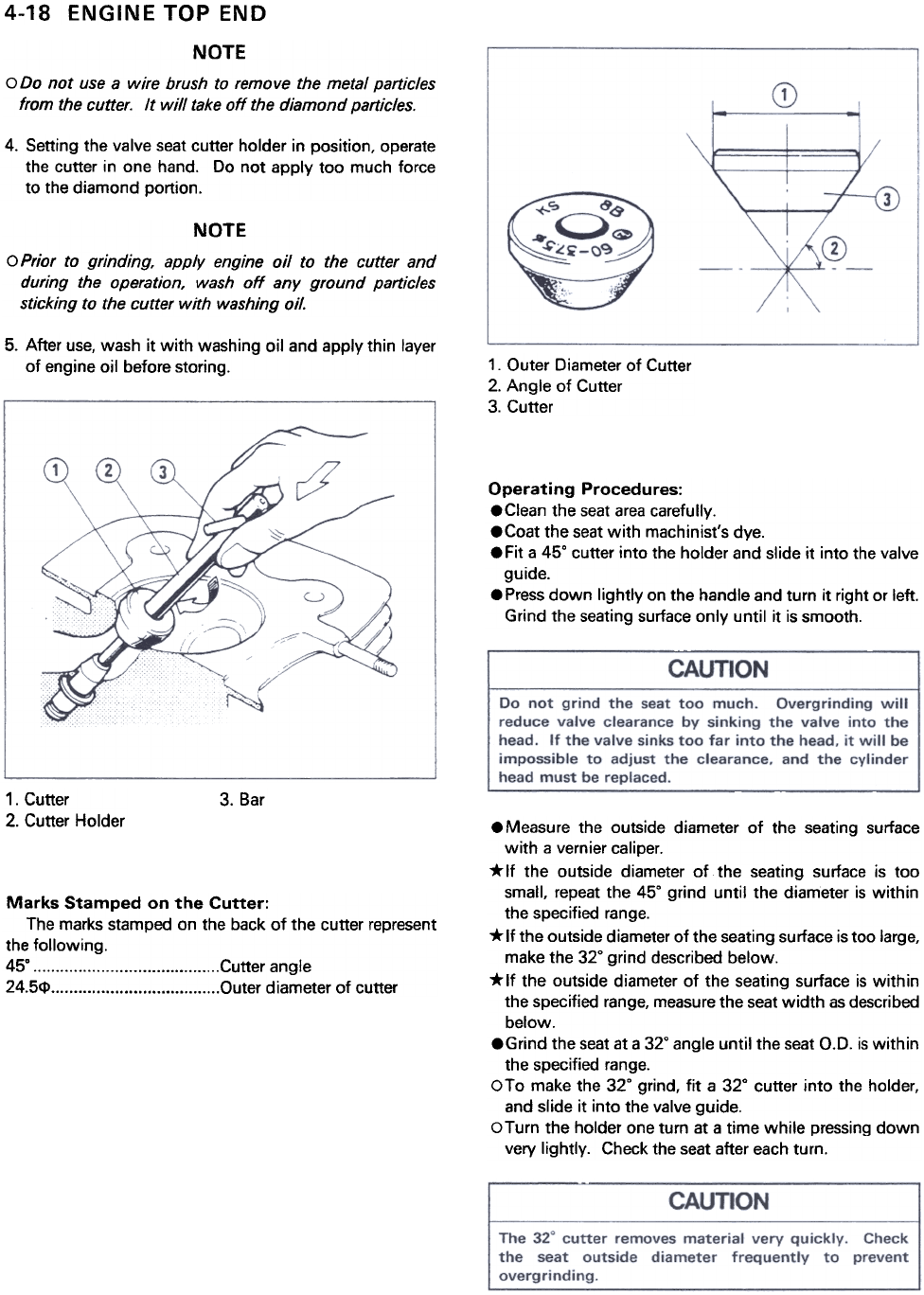

1. Outer Diameter of Cutter

2. Angle of Cutter

3. Cutter

Operating Procedures:

.Clean the seat area carefully.

.Coat the seat with machinist's dye.

.Fit a 45° cutter into the holder and slide it into the valve

guide.

.Press down lightly on the handle and turn it right or left.

Grind the seating surface only until it is smooth.

1. Cutter

2. Cutter Holder

3. Bar

Marks Stamped on the Cutter:

The marks stamped on the back of the cutter represent

the following.

45° Cutter angle

24.5<1> Outer diameter of cutter

.Measure the outside diameter of the seating surface

with a vernier caliper.

*If the outside diameter of the seating surface is too

small, repeat the 45° grind until the diameter is within

the specified range.

*If the outside diameter of the seating surface is too large,

make the 32° grind described below.

*If the outside diameter of the seating surface is within

the specified range, measure the seat width as described

below.

.Grind the seat at a 32° angle until the seat O.D. is within

the specified range.

OTo make the 32° grind, fit a 32° cutter into the holder,

and slide it into the valve guide.

OTurn the holder one turn at a time while pressing down

very lightly. Check the seat after each turn.