ENGINE

3.38

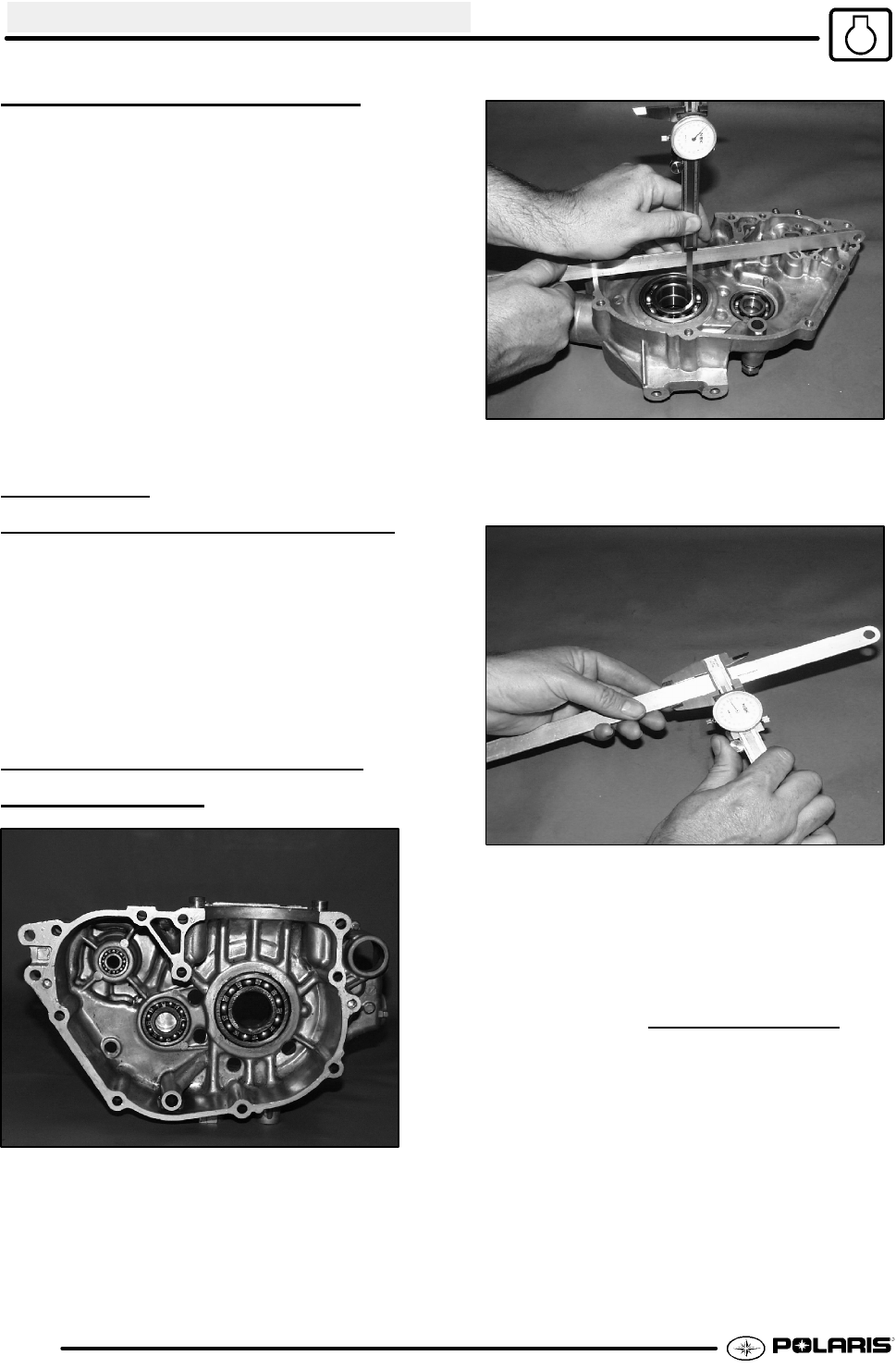

BEARING INSTALLATION

NOTE: To ease bearing installation, warm the

crankcase until hot to the touch. Place the bearings in

a freezer.

1. Install the bearings so the numbers are visible.

2. Drive or press new bearings into the crankcases,

using the proper driver. CAUTION: Press only on

outer race of bearing to prevent bearing damage.

S 70 mm (2.755″) driver- For

crankshaft main bearings.

S 46 mm (1.810″) For counter balancer

bearings.

S 28 mm (1.100″) For pump shaft

bearing.

END PLAY

INSPECTION/ADJUSTMENT

Before reassembling the crankcase,the following

steps should be performed to determine the amount

of crankshaft, counter balancer shaft, and pump shaft

end play. Excessive end play may cause engine noise

at idle and slow speeds. Too little play will side load

the bearings which may lead to premature bearing

failure.

CRANKSHAFT END PLAY

ADJUSTMENT

1. Make sure all bearings are firmly seated in the

both Mag and PTO crankcase.

2. Measure the distance from the PTO crankcase

mating surface to the main bearing using a dial

caliper and a straight edge.

3. Subtract the thickness of the straightedge from

the measurement obtained in Step 2 and record.

PTO Case Depth