FINAL DRIVE

7.25

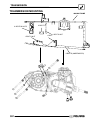

5. Refit CV joint on interconnecting shaft by tapping

with a plastic hammer on the joint housing. Take

care not to damage threads on the outboard CV

joint. The joint is fully assembled when the snap

ring is located in the groove on the

interconnecting shaft.

Tap joint onto shaft

6. Install and tighten large boot clamp with boot

clamp pliers.

7. Remove excess grease from the CV joint’s

external surfaces and position joint boot over

housing, making sure boot is seated in groove.

Position clamp over boot end and make sure

clamp tabs are located in slots. Note:

Before

tightening boot clamp on inboard

joint, make sure

any air pressure which may have built up in joint

boot has been released. The air should be

released after the plunging joint has been

centered properly. Tighten boot clamp using boot

clamp pliers.

Open snap ring and pull

CV joint away from shaft

(Boot Replacement)

1. Remove CV joint from end of shaft.

2. Remove boot from shaft.

NOTE: When replacing a damaged boot, check the

grease for contamination by rubbing it between two

fingers. A gritty feeling indicates contamination. If

the grease is not contaminated, the boot can be

replaced without cleaning the CV joint. Use the

recommended amount of grease for boot

replacement only (see below). Proceed to Boot

Installation.

(CV JOINT CLEANING / REPLACEMENT)

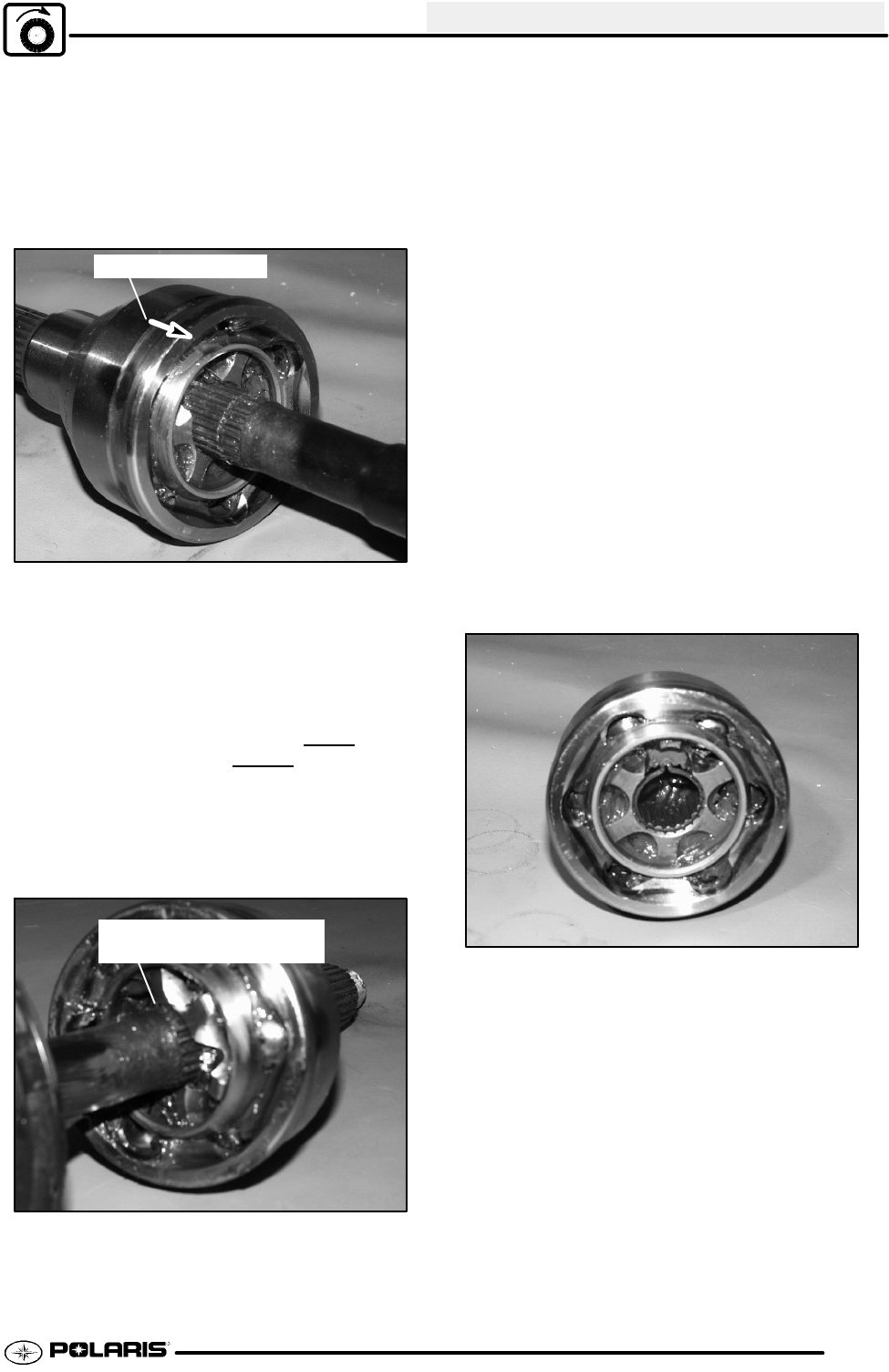

3. Thoroughly clean and dry the CVjoint and inspect

ball tracks and cages for wear, cracks or other

damage.

NOTE: Shiny areas in ball tracks and on the cage

spheres are normal. Do not replace CV joints because

parts have polished surfaces. Replace CV joint only

if components arecracked, broken, worn or otherwise

unserviceable.

4. Add the recommended amount of grease for CV

joint cleaning to the joint as shown below. Be

sure grease penetrates all parts of the joint.