ENGINE

3.52

A

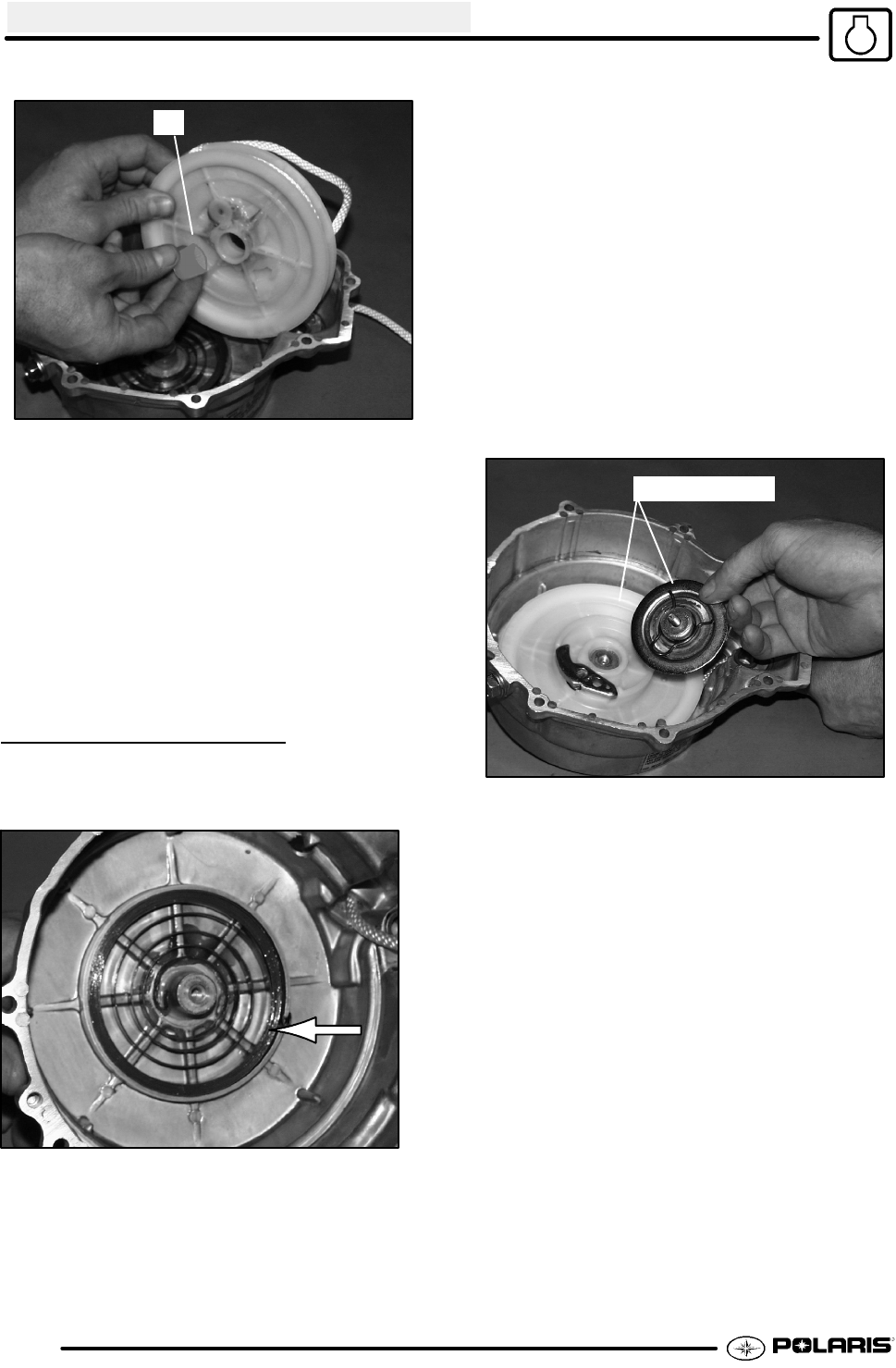

16. Slowly and carefully remove reel from recoil

housing making sure the spring remains in the

housing. Inspect the reel hub and bushing (A) for

wear.

17. Unwind rope and inspect for cuts or abrasions.

18. Inspect drive tab on hub return spring for damage.

To remove hub return spring, hold outer coils in

place with one hand and slowly remove spring

one coil at a time from the inside out.

19. Pull knot out of of recoil reel. Untie knot. Remove

rope from reel.

RECOIL ASSEMBLY

CAUTION: Be sure to wear a face shield and eye

protection when performing this procedure.

To install a new spring:

1. Place spring in housing with the end positioned so

the spring spirals inward in a counterclockwise

direction. See photo at right.

2. Hold spring in place and cut retaining wire.

To reinstall an old spring:

1. Hook outer tab in place in recoil housing and wind

spring in a counterclockwise direction one coil at a

time while holding the installed coils in place.

2. Lubricate the spring with light lubricant such as

Premium All Season Grease (PN 2871423).

To complete recoil assembly:

1. Route rope through guide bushing in recoil

housing and into reel. Tie a secure knot in end of

the rope.

2. Wind rope counterclockwise onto the reel, as

viewed from ratchet side of reel.

3. Lock rope into notch on outer edge of reel.

4. Apply a small amount of grease or equivalent to

the center post of the housing and the bushing.

Open end here

5. Install reel into housing making sure the spring

drive tab on the reel engages the spring and the

reel is fully seated in the housing.

6. Apply downward pressure on the reel and rotate

counterclockwise approximately 6-7 turns to

pre-wind the spring. Continue rotating

counterclockwise until rope on outer edge aligns

with rope guide bushing.

7. Release rope from notch and allow reel to rewind

completely. If more pre-wind is required, place rope

in notch and add additional turns of pre-wind.

8. Install ratchet pawland return spring, withlongleg

of spring engaged in reel.

9. Reinstall friction plate. NOTE: Thefrictionplate

must be positioned with both end tabs of the

friction spring opposite the ratchet pawl.

10. Torque friction plate retaining bolt to 5-6 ft. lbs.

(7-9 Nm).

11. Reinstall recoil housing using a new gasket. Seal

stator wire harness grommet with RTV silicone.