CLUTCHING

6.14

NON--EBS -- DRIVE BELT

TENSION

NOTE: Belt tension is not adjustable on EBS

models.

NOTE: Pinch the sheaves lightly together with clamp

to prevent the belt from being pushed into the driven

sheave.

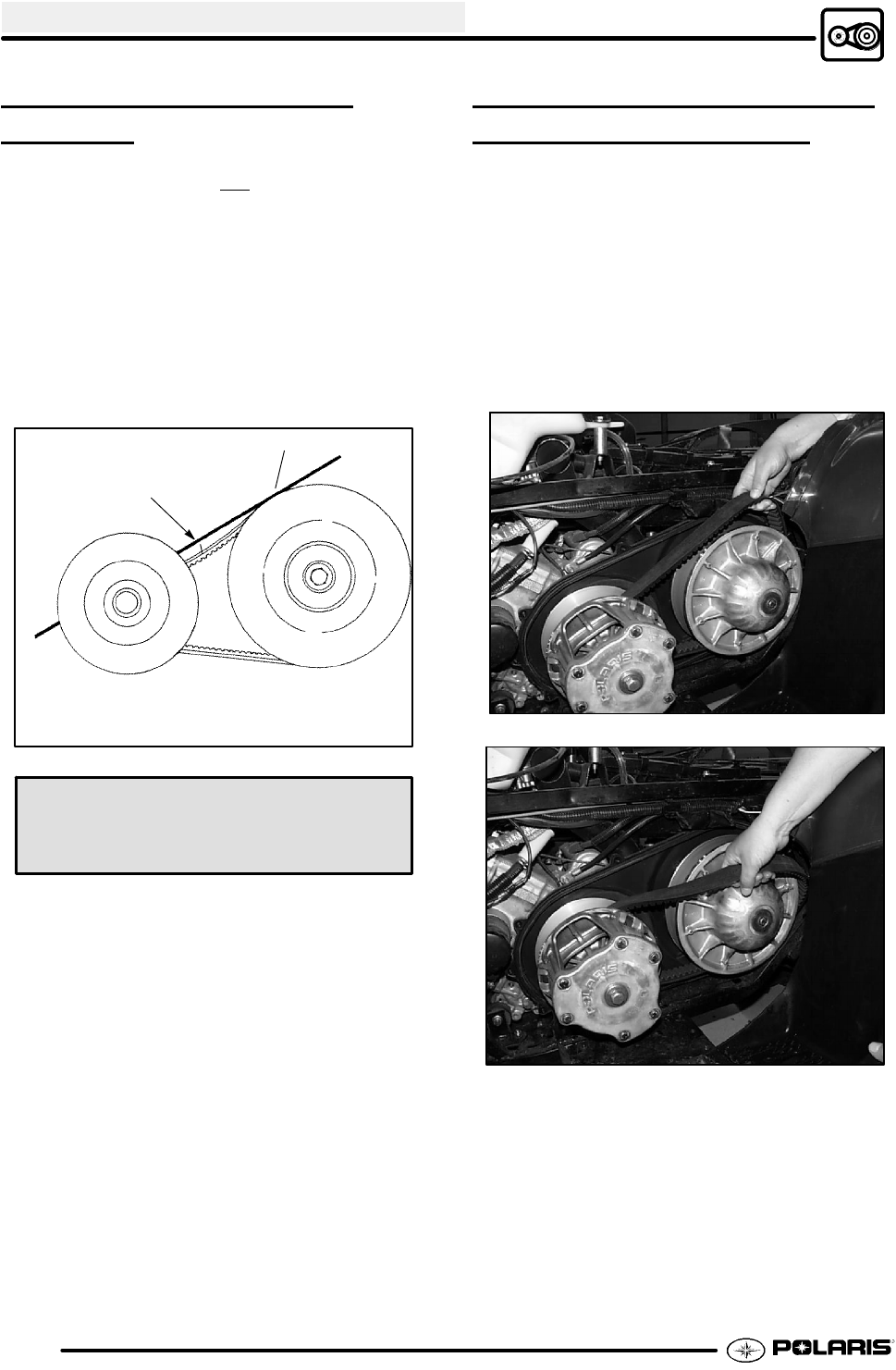

1. Place a straight edge on top of the belt between

drive and driven clutch.

2. Push down on drive belt until it is lightly tensioned.

3. Measure belt deflection as shown in illustration.

11/8″ (28.5 mm)

Straight Edge

Belt Deflection (Tension):

11/8″ (2.9 cm) - 1 1/4″ (3.2 cm)

If belt deflection is out of specification, adjust by

removing or adding shims between the driven clutch

sheaves.

S Remove shims to decrease belt

deflection

S Add shims to increase belt deflection

See Driven Clutch Disassembly/Inspection, Pages

6.19 - 6.20.

NOTE: At least one shim must remain between the

inner and outer sheave of the driven clutch. If proper

belt deflection cannot be obtained, measure drive belt

width, length, and center distance of drive and driven

clutch, outlined in this section; all have an effect on

belt deflection.

ALL MODELS -- DRIVE BELT

REMOV

AL/INSPECTION

1. Remove outer PVT cover as described in PVT

Disassembly.

2. Mark drive belt direction of rotation so that it can

be installed in the same direction. NOTE:

Normally positioned so part numbers are easily

read.

3. To remove drive belt, apply brake, pull upward

and rearward on belt to open driven clutch

sheaves, pull out and down on belt to slip over the

driven clutch outer sheave.

NOTE: When reinstalling thebelt with the drive clutch

and driven clutch already removed follow these steps:

S Install the driven clutch.

S Install the belt onto the driven clutch.

S Loop the drive clutch through the

belt.

S Install the drive clutch onto the

crankshaft.