MAINTENANCE

2.27

CAUTION: Failure to position the crankshaft at TDC

on compression stroke will result in improper valve

adjustment.

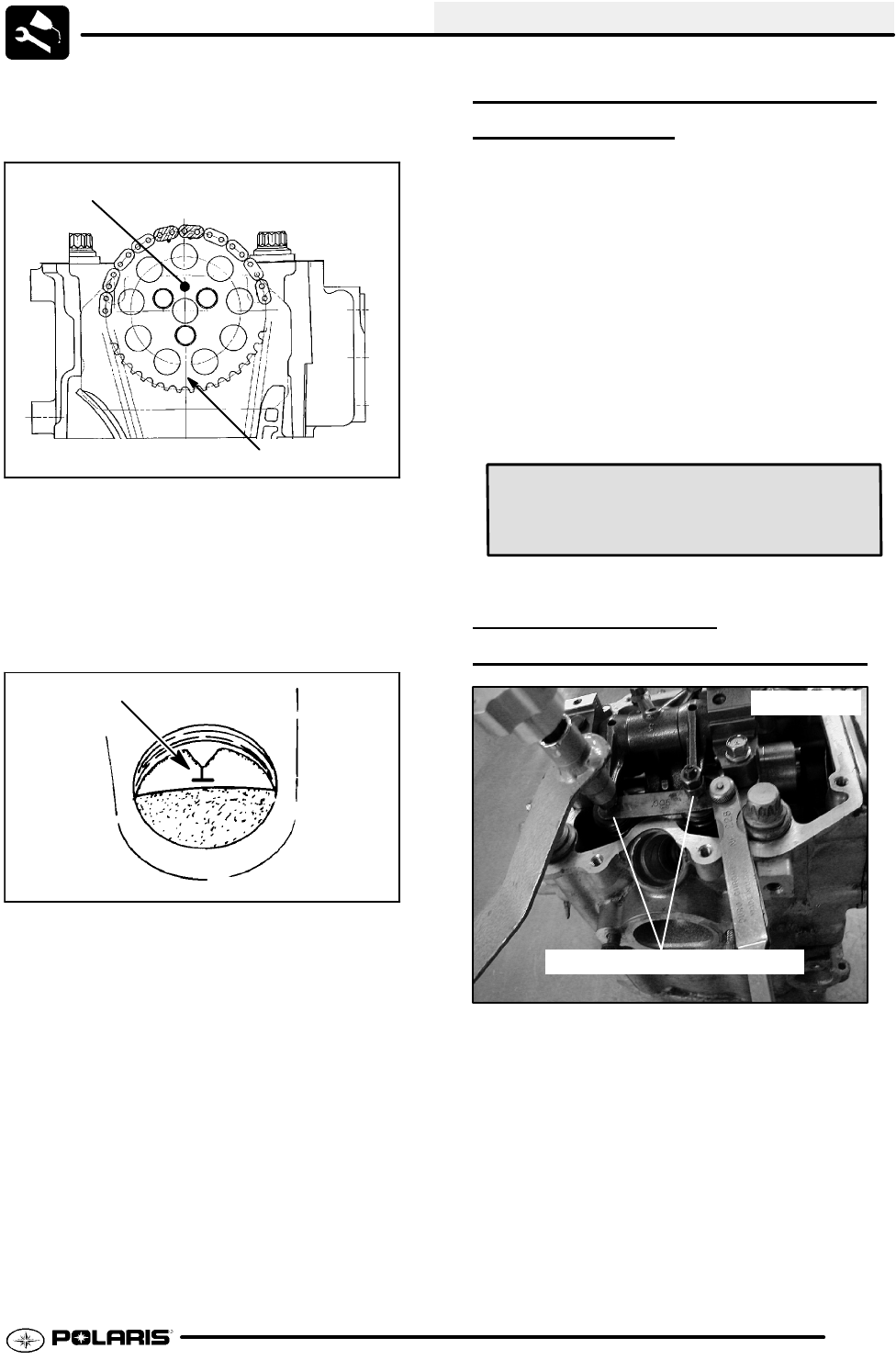

Sprocket alignment pin facing up

Crankshaft-to-Camshaft Centerline

6. Rotate engine slowly with recoil rope, watching

the intake valve(s) open and close.

NOTE: At this point watch the camshaft sprocket

locating pin and slowly rotate engine until locating pin

is facing upward, directly in line with the crankshaft to

camshaft center line as shown. The camshaft lobes

should be pointing downward.

7. Verify accurate TDC positioning by observing the

“T” mark aligned with the pointer in the timing

inspection hole. In this position there should be

clearance on all valves.

INTAKE VALVE CLEARANCE

ADJUSTMENT

1. Insert a .006″ (.15mm) feeler gauge between end

of intake valve stem and clearance adjuster

screw.

2. Using a 10 mm wrench and a screwdriver, loosen

adjuster lock nut and turn adjusting screw until

there is a slight drag on the feeler gauge.

3. Hold adjuster screw and tighten adjuster lock nut

securely.

4. Re-check the valve clearance.

5. Repeat adjustment procedure if necessary until

clearance is correct with locknut secured.

6. Repeat this step for the other intake valve.

.006″ (.15 mm)

INTAKE VALVE CLEARANCE

EXHAUST VALVE

CLEARANCE

ADJUSTMENT

Feeler Gauge for Both Valves

500 Engine

NOTE: The exhaust valves share a common rocker

arm, and must be adjusted using two feeler gauges.

1. Insert .006 feeler gauge(s) between end of

exhaust valve stem and adjuster screw(s).

2. Loosen locknut(s) and turn adjuster screw(s) until

there is a slight drag on feeler gauge(s). The

Valve/Clutch Adjuster Tool (PA--44689) can be

used to adjust the engines valves. NOTE: Both

feeler gauges should remain inserted during

adjustment of each valve.